Chapter 1 Before Use

1-11

1

2

2

2

2

4

When charging is complete, remove the IC

chip.

5

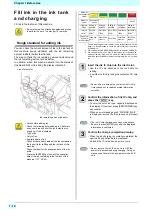

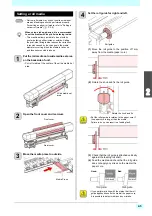

Take out the ink bottle, and slowly shake it

twenty times and more.

• To prevent ink from leaking when you shake it,

wear gloves and cover the ink bottle cap with a

paper towel etc. Being in that status, slowly shake

it twenty times and more by flowing ink.

6

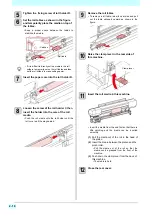

Remove the cap of the ink tank.

• First, cover the cap with a waste cloth etc. to

prevent your hands from getting dirty and then

remove it.

7

While checking the ink remaining amount

indicator, add ink.

• Depending on the ink type, aluminum sheet

adheres to the bottle top surface. In such a case,

remove it with a cutter.

• While checking the ink remaining amount

indicator below the ink tank, add ink. For details,

refer to P.1-25 “Rough standard for adding ink”.

8

Attach the ink tank cap firmly.

9

Lightly press down the ink tank.

• Press down the ink tank about 5 mm so that this

machine can correctly recognize the amount of

refilled ink. Then slowly replace the ink tank.

• After charging is complete, be sure to remove and

dispose of the IC chip. Do not reuse IC chips.

• If the error message “INVALID INK CHARGE”

appears on the display

• Charging was not possible for one or more of the

following reasons:

(1)

Faulty IC chip

(2)

The remaining amount of ink managed by

this machine is “FULL”.

(3)

Attempting to charge ink that has passed its

expiration date

• Before shaking it, check that the cap is firmly

closed.

• If you shake it too strong, it may cause ink

leakage. Therefore, perform this carefully.

• If the remaining amount of ink is less, ink in the

bottle cannot be beaten enough. Tilt the ink bottle

until it becomes vertical.

Cover with paper towel firmly and shake ink slowly

Repeat this

Cap

• Attach the cap firmly.

• UV ink may be cured by ultraviolet. If the cap is not

attached firmly after you add ink, it may cause

adverse effects on ink in the tank and it may

become unusable.

• Do not press down the ink tank 10 mm or more.

After pressing down the ink tank, be sure to slowly

replace the tank.

If the ink tank is returned intensely, the amount of

ink cannot be accurately detected.

• Do not press down the ink tank with strong force. It

may damage the tank.

• The ink tank, when containing 3 L or more of ink,

may not come down sufficiently even if you try to

press down the tank. In such a case, do not force

down the tank any more.

Содержание SIJ-320UV

Страница 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Страница 13: ...xii Warning labels 1 2 2 2 2 2 1 No Reorder Label 1 M905811 2 M903330 3 M905980 4 M907935 5 M903239 6 M903404 ...

Страница 14: ...xiii Warning labels ...

Страница 28: ...1 14 Chapter 1 Before Use ...

Страница 98: ...4 26 ...

Страница 116: ...5 18 Chapter 5 Troubleshooting ...

Страница 122: ...Chapter 6 Appendix 6 6 ...

Страница 124: ...MM FW 1 50 MIMAKI ENGINEERING CO LTD 2015 ...