4-9

4

2

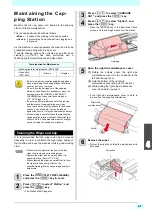

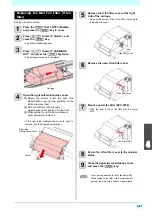

Washing the Ink Discharge Passage

Wash the ink discharge passage on a regular basis (once

every 2 - 3 months) to prevent ink coagulation from

clogging the passage.

1

Press the

(TEST PRINT/CLEANING)

,

and press the

key in Local.

2

Press

to select “Station”, and

press the

key.

• The Station MENU appears.

3

Press

to select “Pump Tube

Wash”, and press the

key.

• Press the [ENTER] key in the Execution Check

screen, and the carriage moves over the platen.

• Dry suction operation is performed repeatedly

until the washing work is completed.

4

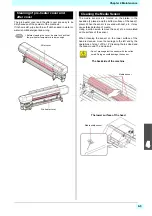

Open the right side maintenance cover.

(1)

Rotate the screws under the right side

maintenance cover (for two positions) to the

left and remove them.

(2)

Hold the bottom of the right side

maintenance cover and pull it to the front.

(3)

While pulling the right side maintenance

cover downward, remove it.

• If the right side maintenance cover is hard to

remove, use the supplied screwdriver.

5

Suction the cleaning solution into a

syringe and squirt about three syringes

worth of solution into each cap.

6

Close the right side maintenance cover

and press the

key.

• After running a dry suction for a certain period of

time?the screen returns to step2.

Carriage

Right side

maintenance cover

Screw

Содержание SIJ-320UV

Страница 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Страница 13: ...xii Warning labels 1 2 2 2 2 2 1 No Reorder Label 1 M905811 2 M903330 3 M905980 4 M907935 5 M903239 6 M903404 ...

Страница 14: ...xiii Warning labels ...

Страница 28: ...1 14 Chapter 1 Before Use ...

Страница 98: ...4 26 ...

Страница 116: ...5 18 Chapter 5 Troubleshooting ...

Страница 122: ...Chapter 6 Appendix 6 6 ...

Страница 124: ...MM FW 1 50 MIMAKI ENGINEERING CO LTD 2015 ...