.

A complete Parts List is available at www.MillerWelds.com

OM-264 267 Page 14

SECTION 5

−

INSTALLATION

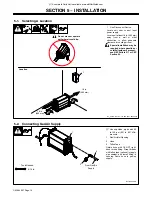

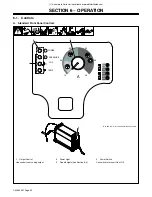

5-1. Selecting A Location

loc_2 3/96 - Ref. ST-151 556 / Ref. 264 254-B

1

Line Disconnect Device

Locate unit near correct input

power supply.

Locate unit at least 18 in. (460 mm)

away from a wall or other

obstruction to allow adequate

clearance for cooling air flow.

!

Special installation may be

required where gasoline or

volatile liquids are present

−

see NEC Article 511 or CEC

Section 20.

Location

1

18 in.

(460 mm)

18 in.

(460 mm)

!

Do not move or operate

unit where it could tip.

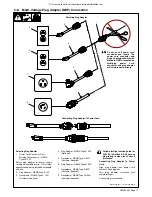

5-2. Connecting Gas/Air Supply

Ref. 805 326-A

.

Use only clean, dry air with 90

to 120 psi (621 to 827 kPa)

pressure.

1

Gas/Air Inlet Opening

2

Hose

3

Teflon Tape

Obtain hose with 1/4 NPT right-

hand thread fitting. Wrap threads

with teflon tape (optional) or apply

pipe sealant, and install fitting in

opening. Route hose to gas/air

supply.

Tools Needed:

9/16 in.

3

From Gas/Air

Supply

1

2

Содержание XT40 Torch

Страница 23: ...A complete Parts List is available at www MillerWelds com OM 264 267 Page 19 Notes...

Страница 40: ...OM 264 267 Page 36 SECTION 9 ELECTRICAL DIAGRAM Figure 9 1 Circuit Diagram For Spectrum 625 X TREME...

Страница 41: ...OM 264 267 Page 37 264 143 A...

Страница 42: ...OM 264 267 Page 38 Figure 9 2 Circuit Diagram For Spectrum 625 X TREME CNC...

Страница 43: ...OM 264 267 Page 39 265 480 A...

Страница 48: ...Notes...

Страница 50: ...Notes Work like a Pro Pros weld and cut safely Read the safety rules at the beginning of this manual...