.

A complete Parts List is available at www.MillerWelds.com

OM-264 267 Page 16

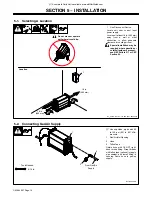

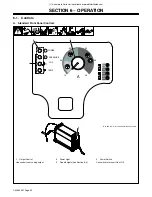

5-5. Connecting Work Clamp

Ref. 803 640-A

1

Work Clamp

2

Workpiece

Connect work clamp to a clean,

paint-free location on workpiece, as

close to cutting area as possible.

1

2

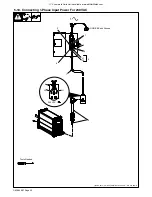

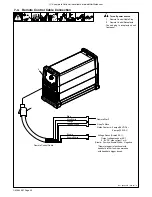

5-6. Electrical Service Guide

Elec Serv 2014

−

01

Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These

recommendations are for a dedicated circuit sized for the rated output and duty cycle of the welding power source.

In dedicated circuit installations, the National Electrical Code (NEC) allows the receptacle or conductor rating to be less than the rating

of the circuit protection device. All components of the circuit must be physically compatible. See NEC articles 210.21, 630.11, and

630.12.

NOTICE

−

Actual input voltage should not be 10% less than minimum and/or 10% more than maximum input voltages listed in table. If actual input

voltage is outside this range, output may not be be available.

60 Hz Single Phase

Input Voltage (V)

120

240

Input Amperes (A) At Rated Output

A 15 or 20

ampere individual

branch circuit

protected by

time-delay fuses

or circuit breaker

is required.

See Section 4-2

27

Max Recommended Standard Fuse Rating In Amperes

1

Time-Delay Fuses

2

35

Normal Operating Fuses

3

45

Min Input Conductor Size In AWG

4

10

Max Recommended Input Conductor Length In Feet (Meters)

130

(40)

Min Grounding Conductor Size In AWG

4

10

Reference: 2014 National Electrical Code (NEC) (including article 630)

1 If a circuit breaker is used in place of a fuse, choose a circuit breaker with time-current curves comparable to the recommended fuse.

2 “Time-Delay” fuses are UL class “RK5” . See UL 248.

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amps), and UL class “H” ( 65 amps and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.15(B)(16). If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable

requirements.

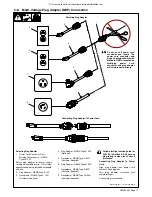

5-7. Extension Cord Data

.

When calculating max. cord length, remember to include conductor length from line disconnect device to input power receptacle.

Single Phase AC

Input Voltage

Conductor Size

−

AWG (mm

2

)*

6 (13.3)

8 (8.4)

10 (5.3)

12 (3.3)

14 (2.1)

Maximum Allowable Cord Length in ft (m)

120

182 (55)

114 (35)

72 (22)

45 (14)

29 (9)

240

340 (104)

210 (64)

130 (40)

−

−

−

−

*Conductor size is based on maximum 3% voltage drop

Содержание XT40 Torch

Страница 23: ...A complete Parts List is available at www MillerWelds com OM 264 267 Page 19 Notes...

Страница 40: ...OM 264 267 Page 36 SECTION 9 ELECTRICAL DIAGRAM Figure 9 1 Circuit Diagram For Spectrum 625 X TREME...

Страница 41: ...OM 264 267 Page 37 264 143 A...

Страница 42: ...OM 264 267 Page 38 Figure 9 2 Circuit Diagram For Spectrum 625 X TREME CNC...

Страница 43: ...OM 264 267 Page 39 265 480 A...

Страница 48: ...Notes...

Страница 50: ...Notes Work like a Pro Pros weld and cut safely Read the safety rules at the beginning of this manual...