OM-257 675 Page 36

9-3. Automated Welding Equipment Recommendations

Planning proper layout and routing of welding cables and control cables should be considered when setting up automated equipment.

1.

Whenever possible all cables should be routed out of the path of moving equipment.

2.

Cable installation in a stationary position will decrease the likelihood of wires breaking down in the cable.

3.

Cables that are moving will breakdown over time. This time can be increased by making sure there are no stress points when installing cables,

and deciding how and where to tie cables down.

4.

If at all possible, do not route weld cables and control cables together. Leave as much space as reasonable between the weld cables and any

other control cables. Welding generates electrical noise which is present on the weld cables (see 9-9 for grounding information).

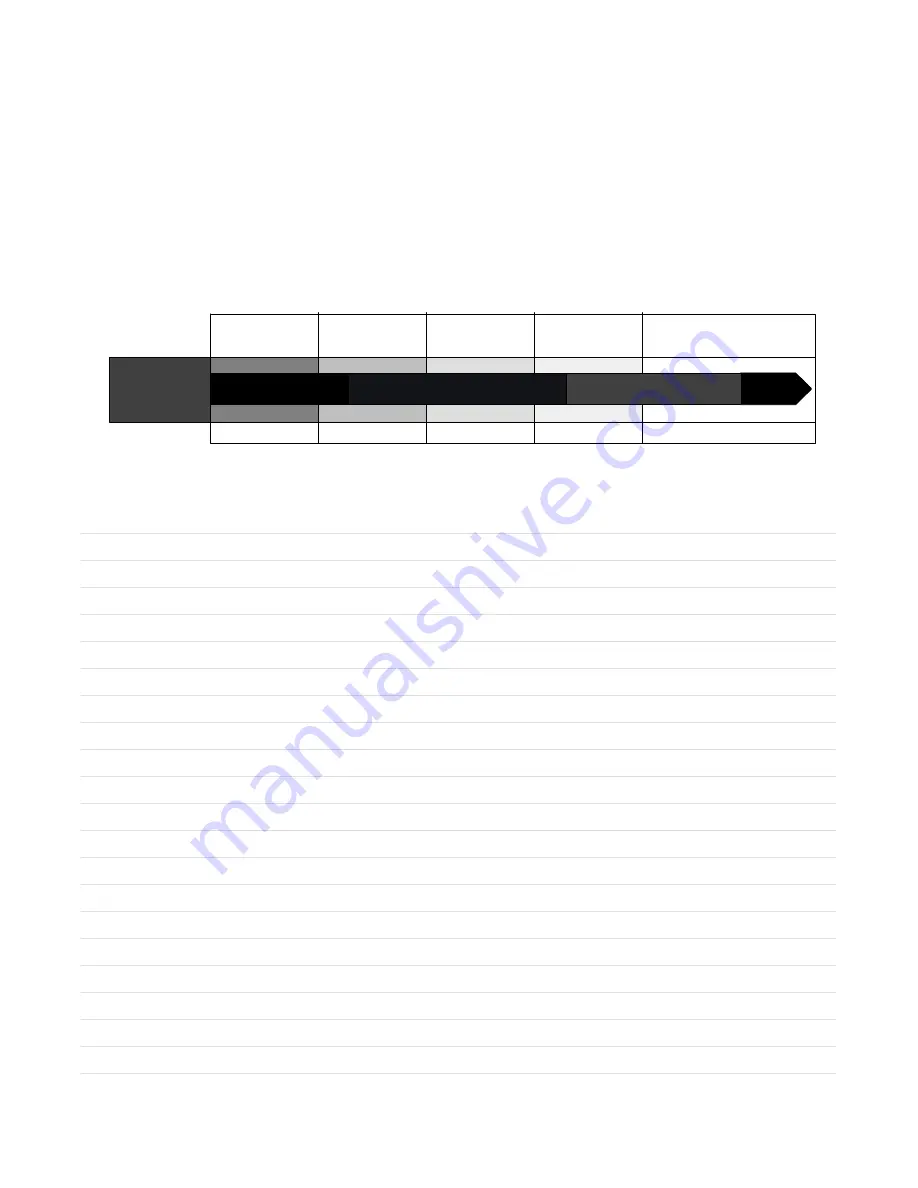

9-4. Process Considerations

To obtain the most performance from the welding equipment, it is important to use the right transfer mode for the application. There are no hard and fast

rules, but there are general guidelines to follow when making a selection. The transfer modes available depend on the power source being used. The

possible transfer modes are as follows: Short Arc, Spray, Pulsed Spray, Accu-pulse, and RMD (Regulated Metal Deposition).

Weld Puddle

Control

Process

Standard

Spray

Pulsed

Spray

Accu-pulse

t

Standard

Short Circuit

RMD

t

Regulate Metal

Deposition

Flat/Horizontal

All Position Performance

Thin Material/Gap Filling

Note: To achieve optimum performance, 4/0 welding secondary cable is recommended and the supplied work sense lead must be

connected as close to the arc as possible.

Notes

Содержание Auto-Axcess E Digital

Страница 6: ......

Страница 16: ...OM 257 675 Page 10...

Страница 18: ...OM 257 675 Page 12 Notes...

Страница 22: ...OM 257 675 Page 16 Notes...

Страница 26: ...OM 257 675 Page 20 Notes...

Страница 30: ...OM 257 675 Page 24 Notes...

Страница 37: ...General OM 257 675 Page 31 Notes...

Страница 98: ...Safety OM 257 675 Page 92 Notes...

Страница 115: ...Trouble OM 257 675 Page 109 Notes...

Страница 120: ...OM 257 675 Page 114 Figure 15 2 Circuit Diagram For Auto Axcess E 300 Digital Welding Power Source Part 2 Of 2...

Страница 121: ...Circuits OM 257 675 Page 115 257 679 A Part 2 Of 2...

Страница 122: ...OM 257 675 Page 116 Figure 15 3 Circuit Diagram For Auto Axcess E 450 Digital Welding Power Source Part 1 Of 2...

Страница 123: ...Circuits OM 257 675 Page 117 257 678 A Part 1 Of 2...

Страница 124: ...OM 257 675 Page 118 Figure 15 4 Circuit Diagram For Auto Axcess E 450 Digital Welding Power Source Part 2 Of 2...

Страница 125: ...Circuits OM 257 675 Page 119 257 678 A Part 2 Of 2...

Страница 126: ...OM 257 675 Page 120 Figure 15 5 Circuit Diagram For Auto Axcess E 675 Digital Welding Power Source Part 1 Of 2...

Страница 127: ...Circuits OM 257 675 Page 121 257 676 A Part 1 Of 2...

Страница 128: ...OM 257 675 Page 122 Figure 15 6 Circuit Diagram For Auto Axcess E 675 Digital Welding Power Source Part 2 Of 2...

Страница 129: ...Circuits OM 257 675 Page 123 257 676 A Part 2 Of 2...

Страница 130: ...OM 257 675 Page 124 Figure 15 7 Circuit Diagram For Axcess E Digital Module...

Страница 131: ...Circuits OM 257 675 Page 125 257 680 A...

Страница 132: ...OM 257 675 Page 126 Figure 15 8 Circuit Diagram For Motor And Digital I O Interface...

Страница 133: ...Circuits OM 257 675 Page 127 258 246 A...

Страница 143: ...E450 Parts OM 257 675 Page 137 Notes...

Страница 153: ...E675 Parts OM 257 675 Page 147 Notes...