General

OM-257 675 Page 65

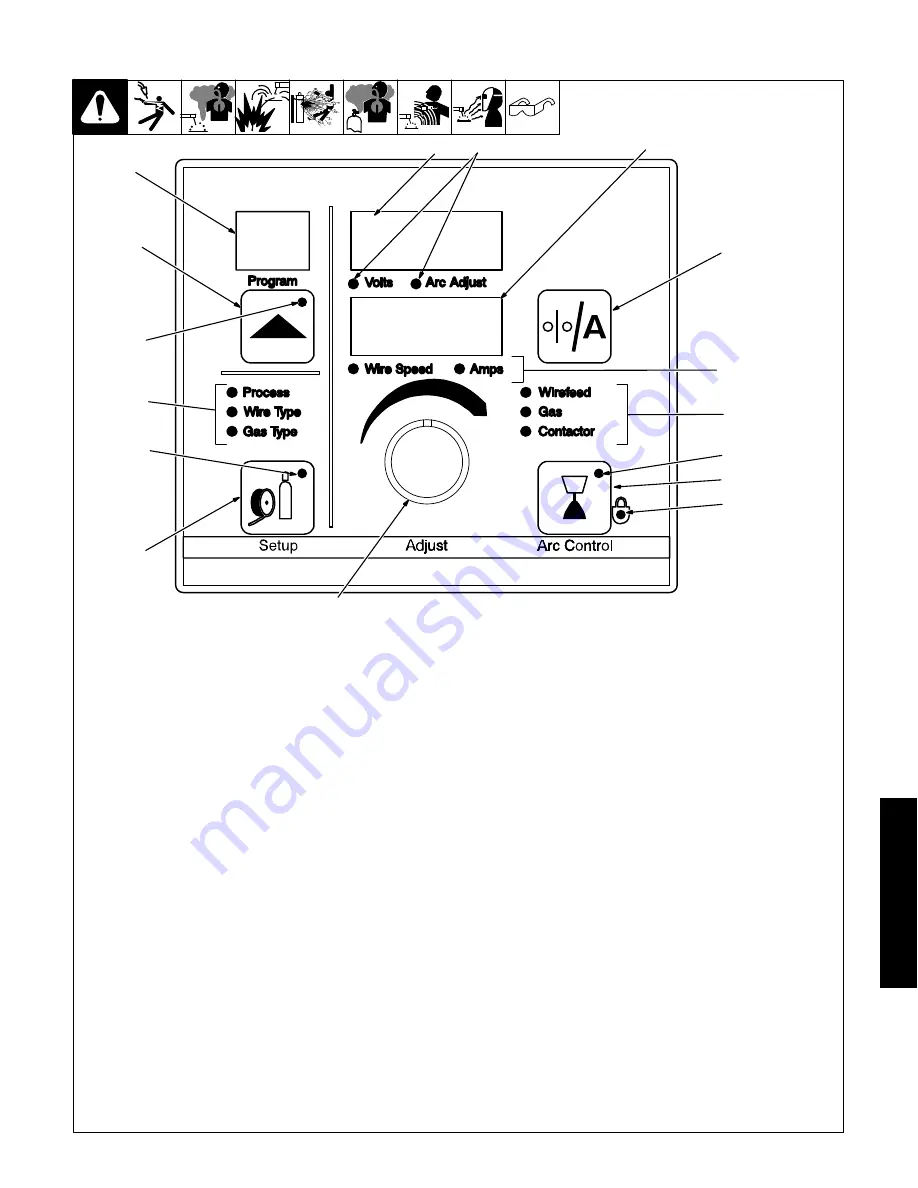

10-3. Front Panel Controls (See Section 10-4)

.

When an LED is lit, it means the related function is active.

1. Program Display

Displays the number of the active program.

2. Adjust Knob

Turn the Adjust knob to change program

number, Setup, Arc Control, and weld

parameters.

3. Program Push Button LED

The LED lights when the Program Push

Button is active.

4. Program Push Button

Press push button (LED lights) and turn Adjust

knob to select active program.

.

The program cannot be changed through

the front panel while welding.

Press and hold button to see program name.

Program name is shown in upper and lower

displays (items 13 and 15).

5. Setup Mode Indicators

The lit LED indicates which setup mode is

active. Setup mode parameters are shown in

Display Windows (see Items 13 and 15).

Process LED

When this LED is lit, turn the Adjust knob to

select the desired weld process. Choices

include pulse welding (displayed as PULS),

Accu-pulse, MIG welding (MIG), AccuCurve,

and RMD [Regulated Metal Deposition

(optional)].

Wire Type LED

When this LED is lit, turn the Adjust knob to

select the desired wire type, wire alloy, and

size. Wire type and size choices vary

according to the selected weld process.

Choices may include steel (displayed as

STL), stainless steel (SS), metal core

(MCOR), aluminum (ALUM). See Table 9-1

for all wire abbreviations.

Gas Type LED

When this LED is lit, turn the Adjust knob to

select the desired weld gas. Gas type choices

vary according to the selected weld process.

See Table 9-1 for all gas abbreviations.

6. Setup Push Button LED

The LED lights to indicate one of the setup

modes is active.

7. Setup Push Button

Press button to select Process, Wire Type,

Wire Diameter, or Gas Type parameters.

.

In order for selections to be retained in

memory, the Setup push button must be

pressed six times before any other push

button is pressed: once to select Process,

again to select Wire Type, again to select

Wire Alloy, again to select Wire Size,

again to select Gas Type, and a sixth time

to store selections in memory. The

displays will temporarily show “PROG

LOAD” to indicate the data is being stored

in memory.

200 410-A

1

3

5

7

2

9

10

11

14

15

4

12

13

6

8

16

Содержание Auto-Axcess E Digital

Страница 6: ......

Страница 16: ...OM 257 675 Page 10...

Страница 18: ...OM 257 675 Page 12 Notes...

Страница 22: ...OM 257 675 Page 16 Notes...

Страница 26: ...OM 257 675 Page 20 Notes...

Страница 30: ...OM 257 675 Page 24 Notes...

Страница 37: ...General OM 257 675 Page 31 Notes...

Страница 98: ...Safety OM 257 675 Page 92 Notes...

Страница 115: ...Trouble OM 257 675 Page 109 Notes...

Страница 120: ...OM 257 675 Page 114 Figure 15 2 Circuit Diagram For Auto Axcess E 300 Digital Welding Power Source Part 2 Of 2...

Страница 121: ...Circuits OM 257 675 Page 115 257 679 A Part 2 Of 2...

Страница 122: ...OM 257 675 Page 116 Figure 15 3 Circuit Diagram For Auto Axcess E 450 Digital Welding Power Source Part 1 Of 2...

Страница 123: ...Circuits OM 257 675 Page 117 257 678 A Part 1 Of 2...

Страница 124: ...OM 257 675 Page 118 Figure 15 4 Circuit Diagram For Auto Axcess E 450 Digital Welding Power Source Part 2 Of 2...

Страница 125: ...Circuits OM 257 675 Page 119 257 678 A Part 2 Of 2...

Страница 126: ...OM 257 675 Page 120 Figure 15 5 Circuit Diagram For Auto Axcess E 675 Digital Welding Power Source Part 1 Of 2...

Страница 127: ...Circuits OM 257 675 Page 121 257 676 A Part 1 Of 2...

Страница 128: ...OM 257 675 Page 122 Figure 15 6 Circuit Diagram For Auto Axcess E 675 Digital Welding Power Source Part 2 Of 2...

Страница 129: ...Circuits OM 257 675 Page 123 257 676 A Part 2 Of 2...

Страница 130: ...OM 257 675 Page 124 Figure 15 7 Circuit Diagram For Axcess E Digital Module...

Страница 131: ...Circuits OM 257 675 Page 125 257 680 A...

Страница 132: ...OM 257 675 Page 126 Figure 15 8 Circuit Diagram For Motor And Digital I O Interface...

Страница 133: ...Circuits OM 257 675 Page 127 258 246 A...

Страница 143: ...E450 Parts OM 257 675 Page 137 Notes...

Страница 153: ...E675 Parts OM 257 675 Page 147 Notes...