Form 44201460

4

Mar 2019

Mestek, Inc. will not recognize the warranty for any use other than space heating.

This heater is for Indoor and Outdoor Installation and is used in Unvented mode. The term Unvented actually means

Indirect Vented. While the products of combustion are expelled into the building, national codes require 4 CFM/1000

BTU of heater input ventilation in the building to dilute these products of combustion. This ventilation may be

provided by gravity or mechanical means.

This heater is not an explosion proof heater. Where the possibility of exposure to volatile and low flash point

materials exists, it could result in property damage or death. This heater must not be installed in a spray booth where

the heater can operate during the spraying process. Consult your local fire marshal or insurance company.

This heater must be applied and operated under the general concepts of reasonable use and installed using best

building practices.

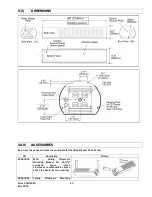

It is the responsibility of the qualified installer to supply the appropriate lifting equipment to safely install the radiant

heater. Tools required for the safe installation, startup and maintenance are various screwdrivers, wrenches, pipe

wrenches, voltmeter, air and gas manometer, level and required tools to safely install the chosen hanging materials.

Do not install this heater indoors in a structure with no insulation in the roof—condensation will

occur.

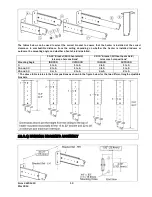

The heater, when installed in aircraft hangars and public garages, must be installed in accordance with ANSI/NFPA

409-latest edition (Standard for Aircraft Hangars), ANSI/NFPA 88a-latest edition (Standard for Parking Structures),

and ANSI/NFPA 88b-latest edition (Standard for Repair Garages) with the following clearances:

a.

At least 10 feet above the upper surfaces of wings or engine enclosures of the highest aircraft that may be

housed in the hangar and at least 8 feet above the floor in shops, offices, and other sections of hangars

communicating with aircraft storage or service areas.

b.

At least 8 feet above the floor in public garages. ▲WARNING: Minimum clearances marked on the heater must

be maintained from vehicles parked below the heater.

(FOR CANADA ONLY)

a.

Installation of this appliance is to be in accordance with latest edition of CSA B149.1 (Natural Gas and Propane

Installation Code).

b.

For installation in public garages or aircraft hangars, the minimum clearances from the bottom of the infrared

heater to the upper surface of the highest aircraft or vehicle shall be 50 percent greater than the certified

minimum clearance, but the clearance shall not be less than 8 feet.

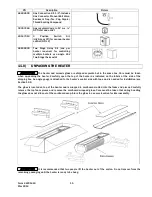

MINIMUM CLEARANCES TO COMBUSTIBLES

4.0)

A critical safety factor to consider before installation is the clearances to combustible materials. Clearance to

combustibles is defined as the minimum distance you must have between the surfaces of the heater and the

combustible item. Considerations must also be made for moving objects around the infrared heater.

This heater must not be installed where the products of combustion can build up and prevent them

being exhausted to the atmosphere. This includes applications such as; enclosures, recessed ceilings and alcoves.

Содержание 44625000

Страница 37: ...Form 44201460 37 Mar 2019...

Страница 45: ......