IM709

31

Unit Options

Duct High Limit

A duct high limit (DHL) pressure control is provided as stan-

dard with all units having variable air volume control. The

duct high limit is intended to protect the ductwork, etc. from

over pressurization caused by tripped fire dampers or a con-

trol failure. When the duct pressure exceeds the setting of the

control, the unit is de-energized via the MicroTech II con-

troller and an alarm condition indicated. After the reason for

trip has been identified and corrected, the control can be

reset via the MicroTech II keypad/display interface.

The duct high limit is preset for a 3.0" w.c. trip point. The

control can be readjusted in the field to match the specific

ductwork of a project. The switch has a field adjustable set

point range of 0.17 to 5.0 inches of H

2

O. Turn adjustment

screw clockwise to decrease differential pressure setting.

Turn adjustment screw counterclockwise to increase differ-

ential pressure setting. The DHL is located in the coil section

on the back side of the control panel.

Phase Fail/Under Voltage Protection

The monitor is a microprocessor controlled device which

provides protection against three-phase electrical motor loss

due to low voltage, phase loss, voltage unbalance and phase

reversal. The microprocessor constantly monitors the three-

phase line voltages and detects these harmful power line

conditions. Whenever any of these conditions occur, the

SWT controls are deactivated and remain deactivated until

power line conditions return to an acceptable level. Trip and

reset delays have been provided to prevent nuisance tripping

due to rapid power fluctuations. The trip and reset delays are

field adjustable. The monitor also provides a variable line

voltage adjustment.

Duct Static Pressure Sensor

All units provided with variable air volume control include a

factory mounted static pressure sensor (SPS1). The unit can

also have an optional second static pressure sensor, SPS2.

The sensor is factory wired and requires field installation of

1/4" l.D. sensor tubing to the selected duct location. Note: Be

sure that tubing complies with local code requirements.

Flame retardant plastic or metal tubing may be required.

Carefully select the ductwork sensing point for the pressure

sensor. Improper location of the sensing point will result in

unsatisfactory operation of the entire variable air volume

system. Follow these guidelines:

1.

Sense near the end of long duct runs to ensure that all

terminal box take-offs along the run will have adequate

static pressure to operate.

2.

The end of the sensing tube must be perpendicular to the

airflow in order to sense only static pressure.

3.

The sensing tube should be located in a non-turbulent

flow area of the duct. Keep several duct widths away

from take-off points, bends or neck downs.

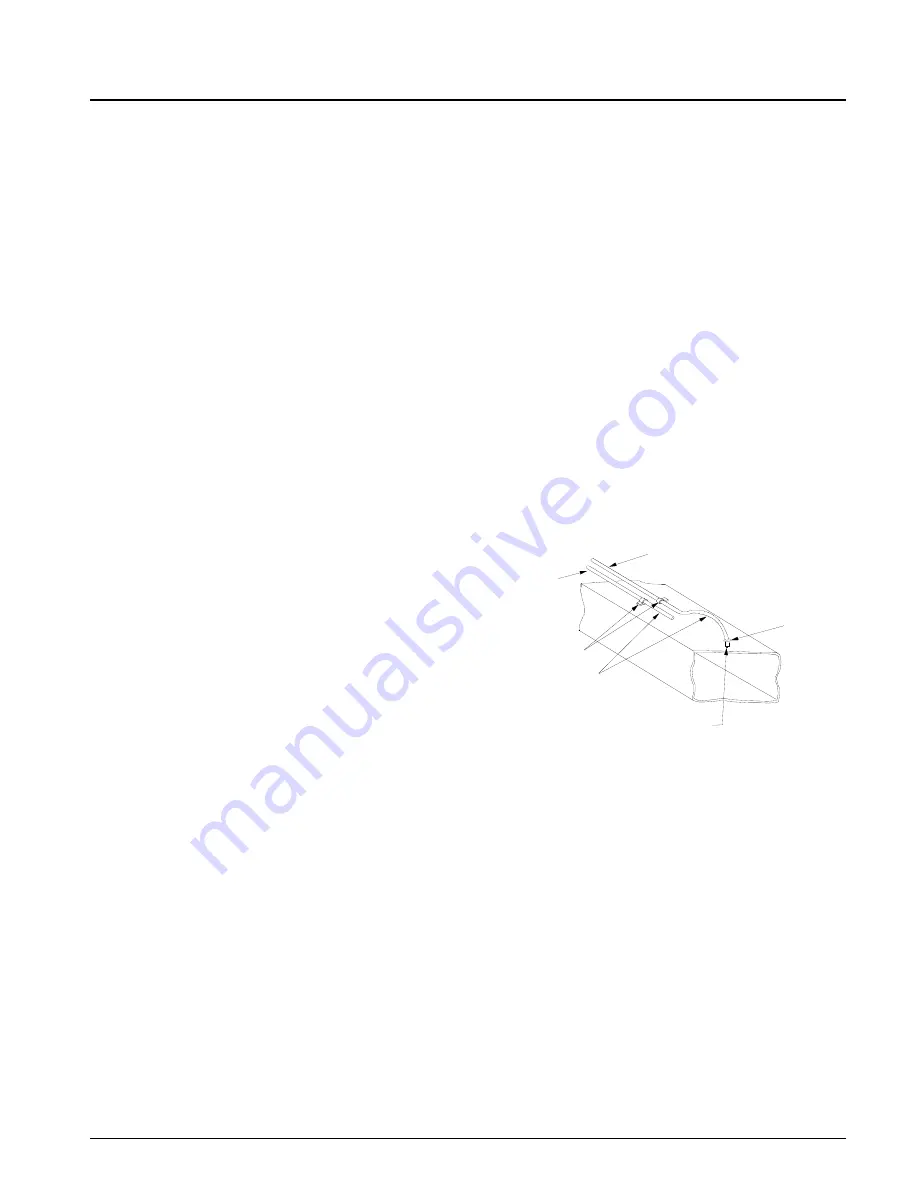

Mounting instructions (see Figure 26)

1.

Drill hole in duct at remote sensing point and install a

rubber grommet. Insert sensing tube 1/8" into the duct

and securely clamp tubing to the duct, being sure not to

stress or kink the tubing. The end of the sensing tube

must be smooth and cut straight across. An angle cut

will affect operation.

2.

Clamp a second tube to the outside of the duct at the

location of the sensing point.

3.

Run both tubes along the ductwork and back to the unit.

The tubing may be routed to the pressure sensor (SPS1)

by drilling two holes through the unit upright post. A

grommet must be used at each hole to protect the tubing

and seal the cabinet. Note: To avoid confusion between

"high" and "low" tubing, it is recommended that two

different tubing colors be used and that this information

be recorded, along with the sensing point location, on

the master building blueprints.

4.

Connect tubing to the high and low ports on the sensor.

Figure 26

Building Static Pressure Sensor

If a unit has direct building static pressure control capability,

static pressure taps must be field installed and connected to

pressure sensor SPS1 in the unit. This sensor is located on

the control panel.

The two static pressure sensing taps must be carefully

located and installed. Improper location or installation of the

sensing taps will cause unsatisfactory operation. Following

are pressure tap location and installation recommendations

for both building envelope and lab, or "space within a space':

pressure control applications. The installation must comply

with local code requirements.

TO SENSOR

"HI" INPUT

TO SENSOR

"LO" INPUT

TUBE CLAMPS

PRESSURE

SENSING

TUBING

RUBBER

GROMMET

TUBING EXTENDS

THRU APPROX. 1/8"

Содержание SWT C Series

Страница 23: ...IM709 23 Typical Wiring Schematics Figure 19 Power Schematic...

Страница 24: ...24 IM709 Figure 20 Input Schematic Discharge Air Control DAC...

Страница 25: ...IM709 25 Figure 21 Input Schematic Zone or Space Comfort Control SCC...

Страница 26: ...26 IM709 Figure 22 Output Schematic Actuator Control...

Страница 27: ...IM709 27 Figure 23 Output Schematic Auxiliary Fan Start Stop Control...

Страница 28: ...28 IM709 Figure 24 Output Schematic Actuator Control...

Страница 29: ...IM709 29 Figure 25 Output Schematic Compressor Control 4 Compressors 4 5 or 6 Stage...

Страница 44: ...13600 Industrial Park Boulevard Minneapolis MN 55441 USA 763 553 5330...