i-32V5H MIDI

Chiller and Inverter Air/Water heat pumps with axial fan

18

LEGEND

EV

1

PLATE HEAT EXCHANGER

W-IN

WATER INLET

DV

1

DRAIN TAP

W-OUT

WATER OUTLET

RV

1

SAFETY VALVE

P

1

ELECTRONIC CIRCULATOR

TE IN

1

WATER INLET TEMPERATURE PROBE

AV

1

AUTOMATIC AIR VENT VALVE

TE OUT

1

USER OUTLET WATER TEMPERATURE PROBE

FC

1

FLOW SWITCH

---

Accessory installed on board

In any case, each unit includes a safety valve with 6 bar opening pressure.

CAUTION: It is recommended to connect the safety valve vent to a suitable conveyor/discharge.

Otherwise, the discharged water could stagnate around the machine and become a danger due to slipping/falling.

3.3.4

Minimum water content and hydraulic circuit volumes

The table shows the minimum recommended plant water content for units The volume of the hydraulic circuit is also indicated.If this volume is

less than the recommended minimum water content, it must be ensured that the pipes connecting to the unit have sufficient capacity to com-

pensate for this difference. The additional volume required is shown in the table.

Model i-32V5H Midi

0121

0126

0128

0132

Minimum system water

content[l]

110

110

110

110

Hydraulic circuit volume [l]

2,4

2,4

3,4

3,4

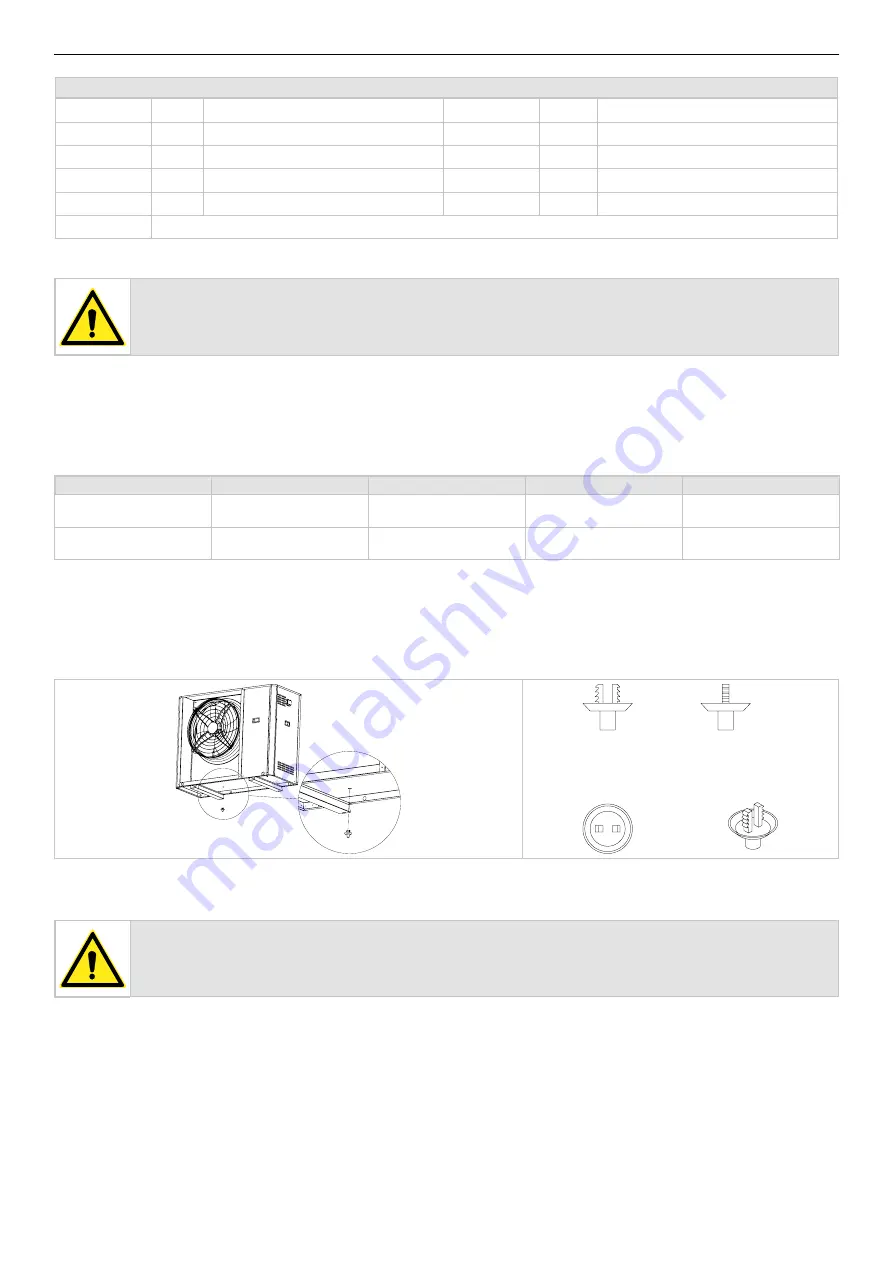

3.3.5 Condensate drainage system

As the pipes are well insulated, the production of condensation is minimal and does not lead to the accumulation of water inside the refriger-

ation compartment. All heat pumps are equipped with a hole in the basement for draining condensation, which is abundant especially in the

post-defrost phase.

FOR HEAT PUMP UNITS, IN PARTICULARLY RIGID CLIMATES, THE INSTALLATION OF THE KA ACCESSORY IS RECOMMENDED, WHICH PREVENTS

THE FORMATION OF ICE ON THE BASEMENT.

CAUTION: for heat pump units, in the event that the prepared ducting system is not used, a limited amount of water

(possible ice in the winter period) from the condensate drainage system may be deposited in the vicinity of the unit, with

consequent danger of slipping/falling.