i-32V5H MIDI

Chiller and Inverter Air/Water heat pumps with axial fan

19

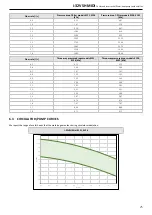

3.3.6 System charging/discharging

CAUTION: supervise all charging/reintegration operations.

CAUTION: Before charging/reintegration the system, disconnect the power supply to the units.

CAUTION: The charging/reintegration of the system must always take place under controlled pressure (1÷3 bar). Make sure

that a pressure reducer and a safety valve have been installed on the charging/reintegration line.

CAUTION: The water in the filling/reintegration line must be pre-filtered from impurities and suspended particles. Ensure

that a removable cartridge filter and a dirt separator are installed.

CAUTION: periodically check and vent the air that accumulates in the system

CAUTION: provide an automatic air release valve at the highest point of the installation

If it is necessary to top up the system or adjust the glycol content, the service tap can be used. Unscrew the

cap of the service tap (A) and connect a 14 or 12 mm pipe (internal diameter measurements - check the tap

model installed on your unit) to the hose connector connected to the water mains, then fill the system by

unscrewing the ring nut (B). After this operation, tighten the ring nut (B) again and screw the cap (A) back on.

In any case, it is advisable to use an external tap to fill the system.

B

A

If the unit must be completely drained, first close the manual inlet and outlet shutters (not supplied) and then disconnect the pipes externally

arranged on the water inlet and outlet in order to drain the liquid contained in the unit (to make the operation easier, it is advisable to install two

external drain cocks on the water inlet and outlet interposed between the unit and the manual shutters).

3.3.7

Air vent valve

È possibile lasciare la valvola in posizione chiusa chiudendo il tappino sullo scarico; allentando il tappino la

valvola rimane in posizione aperta e lo scarico dell’aria avviene in modo automatico The unit is equipped with

an air vent valve that automatically eliminates the air accumulated inside the circuit, avoiding: undesirable

effects such as premature corrosion and wear, lower efficiency and reduced exchange yield.

The device also has a safety function in that, in the event of a break in the exchanger, it allows the refrigerant

gas to escape into the external air, preventing it from being transported to the internal terminals.

It is possible to leave the valve in the closed position by closing the cap on the outlet; by loosening the cap

the valve remains in the open position and the air is discharged automatically.

If you notice a water leak, you must replace the component by unscrewing it with a spanner, as

shown in the image below.