P 5 / 13

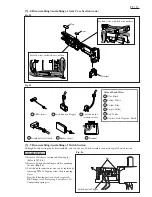

[3] -3. Disassembling/ Assembling/ Adjustment of Angle Head Section (cont.)

[3] -4. Disassembling/ Assembling of Clutch Case Section

ASSEMBLING

1) Assemble Needle bearing 1212, Thin washer 12 and Spacer to Spiral

bevel gear 9.

Caution: Spacer is not reversible when assembled to Spiral bevel gear 9.

Be sure to place as illustrated in Fig. 11.

2) Press-fit Ball bearing 6900LLB to Spiral bevel gear 9 using arbor press

and 1R033. Assemble Retaining ring S-14 to Spiral bevel gear 9

to complete assembling of Spiral bevel gear 9 section.

And then insert Spiral bevel gear 9 section into Angle head complete.

3) Assemble Retaining ring R-22 to Spiral bevel gear 9.

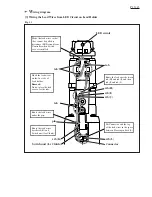

4) Put Internal gear 50 in Angle head complete so that the protrusions on

Internal gear 50 fit in the matching holes on Angle head complete.

(Fig. 15)

5) Assemble Spur gear 14 and Pin 3 (5 pcs each) to Carrier, and then Thin washer 14 and Retaining ring S-14 to complete

Carrier section.

6) Insert Carrier section into Angle head complete, and apply 1.5g of Makita seal lubricant No.101 to Spur gear 14.

7) Install Flat washer 26 and Retaining ring R-32.

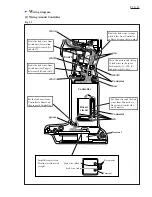

DISASSEMBLING

*Shown in Fig. 16 are the parts of Clutch case

section.

1) Remove Angle head section. (Refer to [3]-1, 3.)

2) Remove Compression spring 2 and Switch lever.

3) Clutch case, Clutch assembly and Compression

spring 5 can be removed by removing four

M4x22 Pan head screws.

4) Remove Retaining ring R-26 using 1R006

or the like.

5) Push out Spur gear 21, and then, after removing

Flat washer 21 using slotted screwdriver or

the like, push out Ball bearing 6803ZZ.

6) Remove Retaining ring S-10 using 1R004 and

1R008 or the like, then Ball bearing 6000DDW

using 1R269 or the like.

Now Spur gear 21 can be replaced.

7) Remove Hex nut M36-41 by turning

counterclockwise. Remove Ring 38, and now

Clutch case can be replaced.

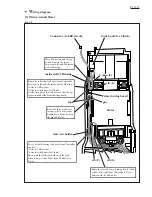

ADJUSTMENT

1) Fasten Angle head complete and Hex nut M36-41 to Clutch case section to the full by hand.

2) Turn Angle head complete counterclockwise to adjust to a desired angle.

3) Being very careful not to turn Angle head complete, fix it securely by turning Hex nut M36-41 clockwise with 1R223

and 1R341 to the recommended torque of 30 -50N.m.

4) Make sure that Lead wires are fixed in place with Lead wire holders as illustrated in Fig. 6.

Then, being careful not to pinch Lead wires, install Lead cover.

Fig. 12

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Angle head complete

two flats

Adjustable wrench

No.1R223

No.1R341

protrusion

Internal gear 50

matching hole

Angle head complete

28) Clutch case

29) Ball bearing 6803ZZ

30) Flat washer 21

31) Spur gear 21

32) Ball bearing 6000DDW

33) Retaining ring S-10

34) Retaining ring R-26

35) Compression spring 5

69) P.H. Screw M4x22 (4pcs)

70) Compression spring 2

71) Switch lever

28

29 30

31

32 33

34

35

69

70

71