P 2 / 13

Warning: Always be sure to disconnect battery cartridge from the machine before starting repair.

Note: See the instruction manual for safety instructions, safety rules and operating instructions.

-- Contents --

[1] Necessary Repair Tools ..................................................................................... III - 1

[2] Grease and Adhesive ......................................................................................... III - 1

[3] Disassembling/ Assembling .............................................................................. III - 2

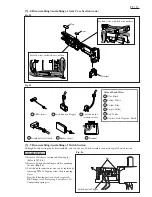

[3] -1. Disassembling/ Assembling of Job Light Section ................................... III - 2, 3

[3] -2. Disassembling/ Assembling of Bearing Retainer .................................... III - 3

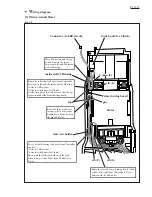

[3] -3. Disassembling/ Assembling/ Adjustment of Angle Head Section ........... III - 3, 4

[3] -4. Disassembling/ Assembling of Clutch Case Section ............................... III - 4, 5

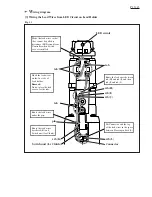

[3] -5. Disassembling/ Assembling of Clutch Section ........................................ III - 5

[3] -6. Disassembling/ Assembling of Gear Case Section .................................. III - 5 -7

[3] -7. Disassembling/ Assembling of Switch Section ........................................ III - 7, 8

[1] NECESSARY REPAIR TOOLS

(Code No.) (Tool Name)

1R004 Retaining Ring Pliers ST-2

1R005 Retaining Ring Pliers RT-2N

1R006 Retaining Ring Pliers RT-2E

1R008 Tips for Retaining Ring Pliers

1R033 Bearing setting Plate 10.2

1R219 Torque Wrench Shaft 7-23N.m

1R220 Ratchet Head 9.5

1R222 Socket Adapter

(Code No.) (Tool Name)

1R223 Torque Wrench Shaft 20-90N.m

1R269 Bearing Extractor

1R291 Retaining Ring S and R Pliers

1R341 Spanner Head

134844-7 Socket 27-50 Ass'y

134848-9 Socket 27-50 Ass'y

765025-8 Torque Adjust Tool

[2] LUBRICATION AND ADHESIVE

See the parts breakdown below.

Apply 2.0g of Makita Grease N. No.2 to the portions designated with the mark of .

Apply Makita seal lubricant to the portions designated with the mark of .

Apply Loc-Tite 603 to the portions designated with the mark of .

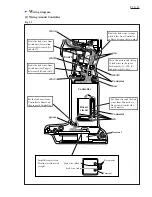

The portions to lubricate with Makita Grease N No.2

48. Three gear shafts of Carrier Complete (A)

51. Spur Gear 13 (3 pcs)

52. Spur Gear 20 Complete

53. Spur Gear 15 (3 pcs)

The portions to lubricate with Makita

Seal Lubricant No. 101

10. Gear room of Angle Head Complete

21. Pin 3 (5 pcs)

22. Teeth of Spur Gear 14

31. Hole on Spur Gear 21

39. Threads on Spindle

40. Steel Ball 5.0 (3 pcs)

43. Steel Ball 4 (3 pcs)

45. steel ball 3 (13 pcs)

63. O Ring 15

The portions to apply Loc-Tite 603

36. Threaded portion of Bearing Retainer 15-26

10

22

21

31

63

64

39 40

43

45

48

51

52

53

Fig. 1

R

epair