Startup/Normal Operation

CIRCUIT BOARD/CONTROL BOARD FUNCTIONS (How does the circuit

board operate?)

When the circuit board is energized (the On/Off button is pushed), the start up cycle is initiated. This

starts a timed 8-15 minute cycle which allows the unit to light. If the unit is on AC power, the automatic

ignition system will energize. The igniter (optional feature) will glow red in the firepot for 10 minutes

and then shut off to protect the igniter. If the unit is on DC back up power the automatic ignition system

will not work and the unit will have to be lit manually. If the proof of fire thermodisk has not reached

operating temperature, the unit will go into the shut down mode. The circuit board is programmed to start

at a specified feed rate regardless of where the heat level setting is set. The unit should be set to the # 2 or

#3 heat level setting for the first 45 minutes. To restart the system if it does not light, push the ON/OFF

button and the startup sequence will start over again. If you open the door, it will stop the startup

sequence.

The circuit board is programmed to start on the # 2 heat setting regardless of what the advance heat

setting is on.

NOTE:

Make sure that the wall thermostat is turned up so the unit will start. (When using T-STAT or

AUTO settings.)

Once the unit is operating at the proper temperature (usually after 10-15 minutes), the circuit board

switches from the start up cycle to normal operation. Then the manual draft slide can be set for the right

fuel load in the firepot.

The unit is not designed to be operated for long periods of time on the highest heat level setting.

Optimum efficiency is achieved by using lower settings (2 or 3). It is also recommended that the unit not

be run for extended periods of time on the #1 heat level setting. The draft blower and venting will fill up

with fly ash after a period of time. It is recommended to run the unit on a higher # heat level setting (2 or

3) once a week. Run it this way for a few hours to clear the venting and draft blower.

With all models, the manual draft will have to be adjusted when the higher (4-5) heat level settings are

used. The circuit board will automatically change the draft and also the room air speed when you change

heat level settings.

If you open the door, ash pan door, hopper lid, have negative

e or place the

unit in a drafty location the vacuum

to shut

down mode. If the unit does not re

ve to be re-set by pressing and

holding the start button for several

Shutdown

or positive pressure in the hom

pressure switch will shut off the auger and the unit will go in

spond, then the pressure switch will ha

seconds, or unplugging the power and starting over again.

To shut the unit down, s

wer will continue to

operate until the low limit/coo

e exhaust fan will

continue to run for an additiona

inutes to make sure there is no exh ust in stove.

imply press the On/Off button. The room fan and exhaust blo

l down sensor tells it that the fire is out. At that point th

l 45 m

a

Before starting the MagnuM Biomass unit again, it is important to remember to clean out the firepot,

empty the ashes, clean out the heat exchangers, vacuum out the hopper if needed and fill the hopper

with fuel.

38

Содержание Winchester WINACI

Страница 21: ...21 MAGNUM WIN INSERT INSTALLATION ...

Страница 25: ...25 ...

Страница 26: ...Fireplace Insert Shroud Installation Diagram 26 ...

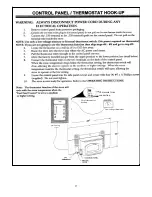

Страница 27: ...27 Thermostat wire connection Low voltage thermostat Molex Plug 24 volt thermostat hookup ...

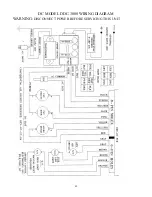

Страница 41: ...AC MODEL WIRING DIAGRAM WARNING DISCONNECT POWER BEFORE SERVICING THIS UNIT 41 DHC 3000 AC board ...

Страница 42: ...42 DC MODEL DDC 3000 WIRING DIAGRAM WARNING DISCONNECT POWER BEFORE SERVICING THIS UNIT ...