10

It is recommended that only an authorized MagnuM installer install your wood pellet stove.

The following installation

guidelines must be followed to ensure conformity with both the safety listing of this stove and to local building codes.

9

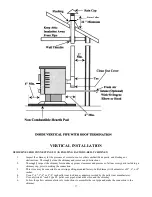

A listed 3” or 4” type “PL” pellet vent exhaust system must be used for FREESTANDING installation and attached to the

pipe connector provided on the back of the stove. Use a 3” to 4” adapter for 4” pipe. A cap must be used at the

termination of type “L” vent chimneys.

9

Do not terminate vent in any

enclosed or semi-enclosed

area, such as; carports, garage, attic, crawl space, under a sundeck

or porch, narrow walkway or closed area, or any location that can build up a concentration of fumes such as a stairwell,

covered breezeway, etc.

9

Vent surfaces can get hot enough to cause burns if touched by children. Non-combustible shielding or guards may be

required.

Do not install a flue damper in the exhaust vent of this unit.

9

Termination must exhaust above air inlet elevation.

It is recommended

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN

that at least 3 ft. of vertical pipe be installed

when the appliance is vented directly through a wall or in a basement.

This will create some natural draft to prevent

the possibility of smoke or odor during appliance shutdown and to keep exhaust from causing a nuisance or hazard from

exposing people or shrubs to high temperatures. In any case, the safest and preferred venting method is to extend the vent

through the roof.

Do not connect this unit to a chimney flue serving another appliance.

9

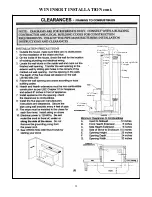

Distance from doors and windows, gravity or ventilation air inlet into building:

Not less that 4 ft. / 1.2 m below, 4 ft. / 1.2 m horizontally from, 1 ft. / 305 mm above (This does not apply if the

windows are non-opening or have been fixed so they cannot open.)

9

Distance from bottom of termination and grade – 1 ft. / 305 mm minimum. This is conditional upon the plants and nature

of grade surface. The exhaust gases are not hot enough to ignite grass, plants or shrubs located in the vicinity of the

termination. The grade surface must not be a lawn. Distance from bottom of termination and public walkway is 7ft. /2.1m

minimum.

9

Distance to combustible materials – 2 ft. / 610 mm. This includes adjacent building, fences, protruding parts of the

structure, roof overhang, plants and shrubs, etc.

9

It is recommended that a single or double clean-out “tee”, for cleaning the vent in both directions, be installed at every 90-

degree junction

to enable collection of fly ash and to permit periodic cleaning of the exhaust system. 90-degree elbows

accumulate fly ash and soot, thereby reducing exhaust flow and performance of the stove.

9

Total length of horizontal vent must not exceed 10 feet / 3,000 mm. All joints in the vent system must be fastened by at

least three (3) screws, and all joints must be sealed with

high temp

RTVsilicone sealer to be airtight.

9

A 3” inch single-wall, stainless steel flexible or rigid exhaust pipe should be used for INSERT installations and must be

attached to the stove with a single-wall, stainless steel “tee” with a clean-out cap. The stainless steel “tee” should be

inclined at 45-degrees to enable the vent to be centered on the stove and allow the “tee” to be cleaned without removing

the stove (see diagram 11.1).

9

When venting into an existing masonry or factory built chimney, the chimney must be cleaned, with all creosote removed.

The chimney must be a type suited for solid fuel.

WARNING:

The chimney and the chimney connections must be kept

clean and in good condition.

9

The “PL” venting or single wall stainless exhaust system must be installed so as to be GAS TIGHT! The vent

manufacturer’s installation procedures must be followed. In addition, pipe connections, joints and all pipe seams within

the home should be sealed with high temperature RTV silicone sealer.

9

If an insert is to be installed into an unlined masonry chimney, it is recommended that a 3” or 4” inch stainless steel pipe

be extended to the top of the existing chimney. The top of the existing chimney should be sealed with a steel plate (see

diagram 11.2).

Содержание Winchester WINACI

Страница 21: ...21 MAGNUM WIN INSERT INSTALLATION ...

Страница 25: ...25 ...

Страница 26: ...Fireplace Insert Shroud Installation Diagram 26 ...

Страница 27: ...27 Thermostat wire connection Low voltage thermostat Molex Plug 24 volt thermostat hookup ...

Страница 41: ...AC MODEL WIRING DIAGRAM WARNING DISCONNECT POWER BEFORE SERVICING THIS UNIT 41 DHC 3000 AC board ...

Страница 42: ...42 DC MODEL DDC 3000 WIRING DIAGRAM WARNING DISCONNECT POWER BEFORE SERVICING THIS UNIT ...