31

OPERATING INSTRUCTIONS…continued (ALL MODELS)

PROPER FUEL

This stove is designed and approved to burn approved Biomass fuel only. Do not use any other type of

fuel. Clean corn with moisture content less than 15% must be used. Factory approved pellets are those ¼”

in diameter and not over 1” in total length. Larger pellets will cause the auger to jam or bridge in the

pellet hopper. The use of unapproved fuel will void all warranties. Do not burn damp or wet pellets. The

stove’s performance depends greatly on the quality of your pellet fuel.

Clean fuel means a consistent and trouble-free operation. Do not use corn/wood pellets that have:

1.

Excess fines

-loose material that looks like sawdust or sand. Loading this material into the

hopper may eventually slow down or jam the auger and prevent the flow of fuel in the hopper

compartment. Dirty Corn (corn cobs, cockle burrs, etc. will plug the auger)

2.

Binders

-material used to hold the pellet together. Wax content corn cannot be used.

3.

High ash content

-avoid pellet brands that immediately smoke up the viewing window and

leave a residue in the burn pot. You will be required to clean the ash boxes and vent pipe more

frequently. It may be necessary to sample several brands until you find a brand of pellets that

will burn properly. Corn supply must be clean, consistent and preferred 11-12% moisture.

RUNNING YOUR STOVE

A.

After starting the stove, leave it burning on the #3 setting for at least 20-30 minutes to allow

the stove to heat to operating temperatures. You may then set the desired burn rate by moving

the control switch to the desired operating position.

B.

Select the most efficient burn by adjusting the air damper control rod in or out. An air damper

closed too much will produce a lazy and slow flame. Adjusted properly, the flames should be

bright and lively. Altitude and fuel types greatly affect the amount of air required. Opening

the damper approximately ¼-1/2 will be sufficient for most installations and fuels.

The

operating temperatures of this unit may vary with the different types or grades of fuel

used.

TURNING THE STOVE OFF

A.

Move the power switch to the “Off” position. (push the On/Off button on the AC & DC

models) The fan will continue to run for approximately 45 minutes to let the stove cool down,

and then automatically shut itself off.

NOTE: IF THIS UNIT RUNS OUT OF FUEL AND COOLS DOWN, THE AUGER WILL STOP

FEEDING. IT WILL BE NECESSARY TO PRIME THE AUGER ANY TIME THE HOPPER

RUNS OUT OF FUEL. THE BLOWERS WILL CONTINUE TO RUN UNTIL THE POWER

SWITCH IS MOVED TO THE “OFF” POSITION.

WARNING:

DO NOT USE ADDITIONAL GRATES TO SUPPORT THE FUEL.

WARNING:

Auger jams are the leading cause of stove malfunctions. Jams occur due to foreign objects

in the fuel, or more commonly, failure to follow the operating instructions. Most auger jams are

preventable by properly priming the auger as required before starting the stove. Keeping the hopper from

running out of fuel will help prevent auger jams.

IMPORTANT:

Selecting the proper combustion air is done by moving the air damper control rod in or

out to decrease or increase the air flow (in = closed = decrease, out = open = increase). High altitude or

high ash fuel may require more air for efficient fuel combustion. The stove should be started with the

damper control rod out in the 1/4 open position.

Содержание Winchester WINACI

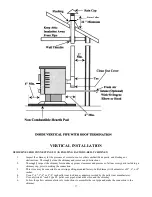

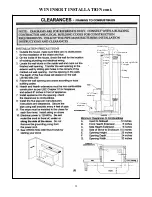

Страница 21: ...21 MAGNUM WIN INSERT INSTALLATION ...

Страница 25: ...25 ...

Страница 26: ...Fireplace Insert Shroud Installation Diagram 26 ...

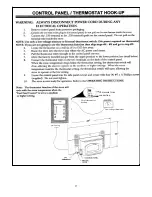

Страница 27: ...27 Thermostat wire connection Low voltage thermostat Molex Plug 24 volt thermostat hookup ...

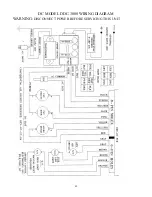

Страница 41: ...AC MODEL WIRING DIAGRAM WARNING DISCONNECT POWER BEFORE SERVICING THIS UNIT 41 DHC 3000 AC board ...

Страница 42: ...42 DC MODEL DDC 3000 WIRING DIAGRAM WARNING DISCONNECT POWER BEFORE SERVICING THIS UNIT ...