IT

EN

FR

ES

13

Madas Technical Manual

- 4|4.1b - REV. 0 of 10

th

May 2018

RG/2M

4.1 - RECOMMENDED PERIODIC CHECKS

• Use a suitable calibrated tool to ensure the bolts are tightened as indicated in 3.2;

• Check the tightness of the flanged/threaded connections on the system;

• Check the tightness and operation of the regulator;

The final user or installer is responsible for defining the frequency of these checks based on the extent of the service conditions.

4.2 - ADJUSTING THE OUTLET PRESSURE

Before starting the system, make sure that the spring supplied with the regulator is suitable for the desired adjustment

pressure. The P2 output pressure (unless specifically requested) is factory set at approximately the minimum calibration value.

Adjust the outlet pressure as follows:

• Set the adjustment screw (

1

) at minimum calibration;

• Start the system or make sure there is a minimum flow downstream of the regulator;

• To increase the pressure calibration downstream of the regulator, tighten the adjustment screw (

1

) to the desired value. Perform

the reading with a calibrated pressure gauge, installed downstream of the regulator to at least 5 DN (see example in 3.4);

• Use pressure outlets (

11

) on the device only for zero flow or very low flow measurements.

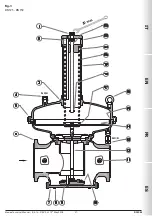

4.3 - REPLACING THE SPRING

The step must be carried out without gas inside the regulator.

• IMPORTANT:

Springs that are: Grey, Red, Brown use the upper spring guide (

21

) code RP-0150/SX

Spring colours: Yellow, Black use the upper spring guide (

21

) code RP-0155/SX

Replace the spring as follows:

• Completely loosen the adjustment screw (

1

) to the stroke end;

• Unscrew the cap (

22

) from the pipe (

19

);

• Remove the spring (

20

) from inside the pipe (

19

);

• If necessary (check spring colour), the upper spring guide (

21

) must be replaced as follows:

• Remove the pin (

18

);

• Keeping the cap (

22

) blocked, turn the fastening screw (

1

) clockwise until the spring guide (

21

) is released from

the guide pin (

2

);

• Remove the spring guide (

21

) completely by turning it clockwise;

• Fit the new spring guide at the end of the threaded bar (

23

);

• Turn the new spring guide anticlockwise in order to secure the threaded bar (

23

), until it is coupled with the pin (

2

);

• Keeping the cap (

22

) blocked in place, turn the adjustment screw (

1

) anticlockwise until the spring guide is at the

opposite end of the threaded bar (

23

);

• Reassemble the pin (

18

).

• Insert the new adjustment spring, making sure to position it correctly inside the lower spring guide (

17

).

• Screw the cap (

22

) to the pipe (

19

).

• Adjust the output pressure as indicated in 4.2.