11

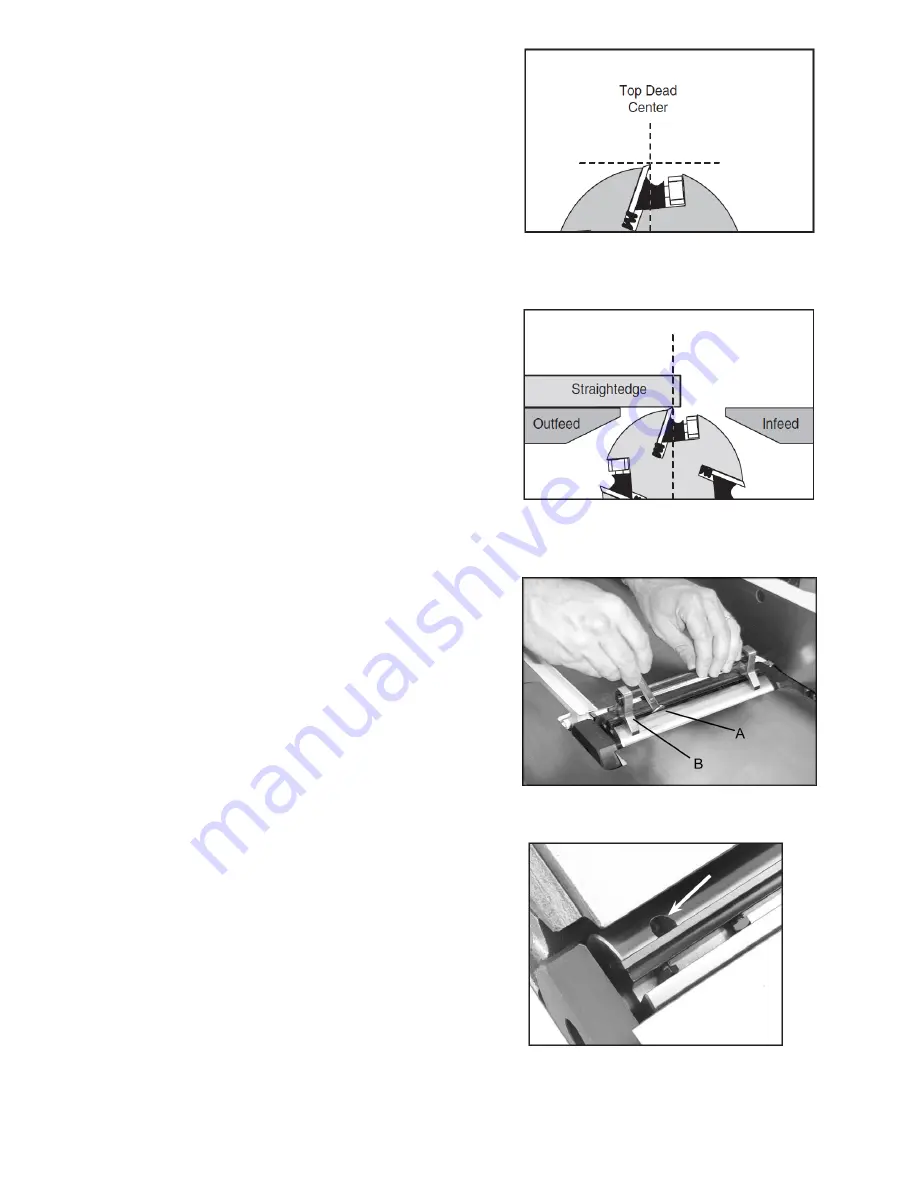

Figure 13

STEP 7&8 with the rest of the knives.

enough to just hold the knife in place. Repeat

pad of the knife setting jog. Snug the gib bolts tight

knife is set correctly, it will bearly touch the middle

screws to raise or lower the knife. When the

cutterhead(Fig. 13) and rotate the jack

jack screws through the access holes in the

the cutterhead over the blade. Find the

Loosen cutterhead gib bolt (A, Fig. 12)

8. Place the knife setting gauge (B, Fig. 12) on

by turning clockwise as viewed from the infeed

table as it is at the back of the table.

is at the same height at the front of the

It must have its knives parallel

it will

After the outfeed table has been set,

Figure 12

Figure 11

should look like Figure 11. Use care when

edge (C, Fig. 9) on the outfeed table and

9). Counter-clockwise will cause the

3. Loosen table lock screw (A, Fig. 9) and

is at top-dead-center(TDC), as shown

cutterhead pulley until one of the knives

Figure 10

table. (Fig. 15)

5. If fence is not square to table, release lock

handle (B, Fig. 14), loosen nut (D, Fig. 14),

and turn bolt (E, Fig. 14) until fence is

square to table.

6. Tighten nut (D, Fig. 14) to retain the setting.

Tighten lock handle (B, Fig. 14).

Figure 15

2. Rotate the cutterhead by turning the

raise the outfeed table to the height of blade

number one by turning handwheel (B, Fig.

outfeed table to raise. Clockwise will cause

the outfeed table to lower.Set a straight

across the cutterhead.

in Fig.10

4. Position of the table and straight edge

handling the straight edge near the blades

so as not to damage them.

5. When the outfeed table and blade number

one (or knife insert) are the same height,

tighten table lock screw.

need no further adjustments to the

cutterhead – skip steps 6 through 9 below.

with the outfeed table. Proceed as follows:

6. Bring the straight edge forward to the front

of the outfeed table and confirm that blade

7. If blade is higher or lower at one point,

table.