10

table so it extends over the cutterhead.

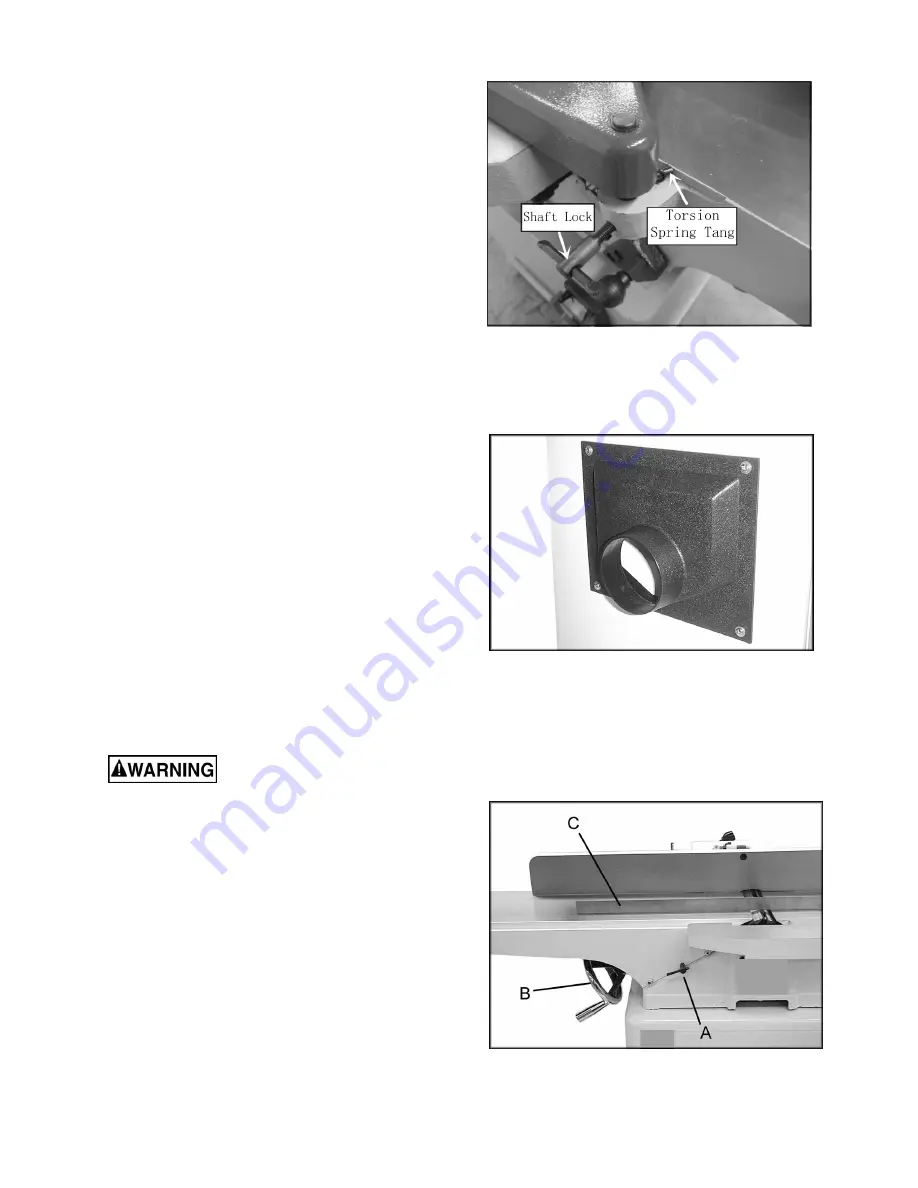

1. Place a strightedge(C Fig. 9) on the out-

Figure 9

reset the outfeed table hight as following:

the outfeed table hight before use, if it is changed,

However, it may change during the shipment, check

Setting Outfeed Table Hight

Attach the dust chute (Fig. 8) to the stand with

Figure 8

repeat STEP 1&2, increasing the spring tension

-If the guard does not snap back, remove it and

-If the guard drags across the table, raise it until

2. Test the guard by pulling in back and

1. Wind the tang the torsion spring back a

so the spring tang points tp the right and reset

half turn, and slide the guard shaft into the casting

Figure 7

Installing Cutterhead Guard

Installing Dust Chute

four screws and four flat washers, through the

pre-tapped holes in the stand.

against the casting.(Fig. 7)

letting go.

-The guard should snap back over the cutterhead

without dragging across the table. If it does,

tighten the shaft lock.

it won't drag, then tighten the shaft lock.

as needed.

Machine should be

disconnected from power source at this

time! Cutterhead blades are extremely sharp!

Use caution when hands are near the

cutterhead!

For most jointing operations, the surface of the

outfeed table must be level with the knife tips of

the cutterhead at their highest point of

revolution. The knife tips must project equally

from the cutterhead.

The outfeed table and cutterhead are adjusted

at the factory and should not require adjustment.