R3-TC2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: [email protected]

EM-8468 Rev.3 P. 5 / 37

FUNCTION DESCRIPTIONS

■

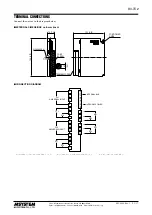

UNIVERSAL INPUT

• Input types

1) DC: 0 − 20mA / -1000 − +1000mV / -10 − +10V

2) Potentiometer: Max. total resistance 4000Ω

3) Resistor: Max. 4000Ω

4) RTD: Pt 100 / Pt 500 / Pt 1000 / Pt 50Ω / JPt 100 /

Ni 508.4Ω / Cu 10

5) Thermocouple: (PR) / K / E / J / T / B / R / S / C / N / U /

L / P

• Two input points can be assigned respectively with one of

the selections (1) through (5).

• Sampling cycle: 100 milliseconds

• Burnout detection available for potentiometer, resistor,

RTD and thermocouple inputs

• Cold junction compensation sensors for thermocouple in-

put included in the product package

• Fine input adjustment available

• DC, potentiometer and resistor inputs can be scaled into

temperature ranges.

• First order lag filter for input signals

■

CONTROL OUTPUT

• Output types

1) 12V pulse / 0 − 20mA DC / 0 − 10V DC

selected by model number suffix code when ordering

2) Open collector

• Two output points by the selection (1) plus two output

points with the selection (2)

• Control cycle 0.1 to 99.9 seconds

(100 msec. fixed for control output 0 − 20 mA and 0 − 10

V DC)

• Output resolution 1 millisecond

• PV, SP and MV signals can be scaled and provided as duty

ratio output; Alarm contact output (ON/OFF) also available

• Minimum ON/OFF pulse width can be specified for relay

life protection

■

CONTROL LOOP

• Control strategies

1) Standard PID control

2) Heating-cooling PID control

(independent PID operation for heating and cooling)

3) Heating-cooling ON/OFF control

(heating-only or cooling-only output is possible.)

• Two control loops can be assigned respectively to one of

the selections (1) through (3).

• Limit cycle method auto-tuning

• Direct/reverse action selectable for standard PID control

• Input 2 can be cascaded to loop 1 as its SP (remote SP)

• MV tracking function: MV in manual mode is carried on

into auto mode.

• High/low limits selectable for SP and MV values

• Specific MV values applicable at STOP/abnormality.

• Three PV alarm modes selectable for each loop

• Four bank settings available for each loop; Banks can be

switched during operation.

• Bank setting

• SP / SP rise ramp / SP fall ramp / P / I / D / Cooling P /

Cooling I / Cooling D / Heating sensitivity / Cooling sensi-

tivity / Deadband / PV alarm high/low limits

■

EVENT INPUT

• Two discrete input points can be assigned to a specific

event.

• Event types

• Switching banks / Switching operation / Switching manu-

al/auto mode / Switching local/remote SP

■

CT INPUT

• Input type

M-System clamp-on current sensor (model: CLSE)

• Two input points can be assigned respectively to monitor

specific control output status.

• One signal can watch heater wire break, SSR shortcircuit

failure and overload at once.

• Control output must be turned on for at the minimum

of 110 milliseconds to detect a heater wire break; must

be turned off for at the minimum of 200 milliseconds to

detect an SSR shortcircuit failure.

■

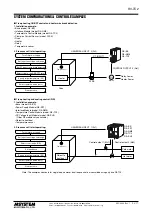

COMMUNICATION

• Monitoring and setting can be performed easily with PC

Configurator Software (model: R3CON).

• Various values can be read out via network communica-

tion (data allocation mode: 8)

• Modbus interface module (model: R3-NM3) available with

the R3 extension area communication realizes a large ca-

pacity data reading/writing.