R3-TC2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: [email protected]

EM-8468 Rev.3 P. 9 / 37

■

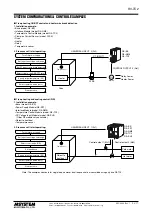

SETTING EXAMPLE 1: TEMPERATURE CONTROL WITH STANDARD PID

The following is an example to control temperature of loop 1 to 40.0°C by standard PID control.

4

8

2

5

4

6

(1) Connect Pt100 to the universal input terminal 1 to measure temperature. Connect also an SSR and a heater to the control

output 1.

SSR

Power Supply

Heater

R3-TC2PS

Pt100

Universal Input 1

Control Output 1

(2) Go to the setting items tree and change the following parameters.

SETTING ITEMS TREE

PARAMETER

SELECTION

Universal input 1

Input type

RTD Pt 100

Universal input 1

Wiring

3 wires

Control output 1

Output assignment

Loop 1, Heating control

Loop 1, Bank 0

SP (setpoint value)

40.0

(3) Confirm that Pt100 is correctly connected to the universal input 1 and the controlled object (heater, etc) for heating control

to the control output 1.

(4) Click RUN button and AUTO button located below the trend graph to start control operations. Indicators STOP and MAN

are switched respectively to RUN and AUTO.

(5) Click Auto-tuning button located below the trend graph to show the Auto-tuning dialog box. Choose Bank 0 and click OK.

(6) The Controller starts auto-tuning. Indicator AT starts blinking. Click STOP button to stop the auto-tuning.

(7) Indicator AT stops blinking to start control operation when the auto-tuning is complete.

(8) Go to the setting items tree and change the following parameters so that the control operation automatically starts at the

start up of the device.

SETTING ITEMS TREE

PARAMETER

SELECTION

Loop 1

Operation at startup

RUN

Loop 1

Control mode at startup

AUTO

Now the setting is complete.