Operation

40

BA-42820-02-V03

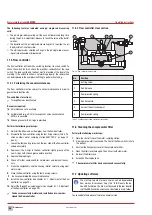

Water sampling station

EASYPRO

Operating instructions

9.5.5.1 1-point adjustment for the conductivity measurement

For calibration purposes, use only KCL buffer solutions (potassium chlo-

ride) for the various measuring ranges in accordance with the following

scheme:

Measuring range

buffer solution

0 –2000 μS/cm

1000 μS/cm = 1 mS/cm

0 – 20 mS/cm

12,88 mS/cm

0 – 100 mS/cm

80 mS/cm

Tab. 40: 1-point adjustment for the conductivity measurement

Pre-conditions for actions:

@

A buffer solution corresponding to the measuring range is on hand

and has the printed temperature.

@

A clean cloth is available.

Perform the following work steps:

1.

Working in the main menu under “Calibration”, navigate to the “Sen-

sors” tab.

2.

Working under “Sensor”, select the sensor that measures the con-

ductivity and which you wish to calibrate.

3.

Press the “1 points” button.

4

1-point calibration begins.

4.

Shut off the sample water.

5.

Unscrew the conductivity measuring cell from the corresponding

measuring cell housing.

6.

Dry the electrode with the cloth to prevent dilution of the buffer solu-

tion.

7.

Hold the conductivity measuring cell in the buffer solution and move

back and forth for a short time.

8.

Enter the value which is recorded on the buffer solution. The meas-

ured current value and the entered value are both displayed.

9.

Wait until the value has stabilised.

10.

Confirm the entry with the green checkmark.

ü

1-point adjustment of the conductivity measurement complet-

ed.

9.5.5.2 Adjusting the conductivity in the setpoint

When controlling the conductivity with your

TOPAX

®

MC

, you can cali-

brate the conductivity close to the setpoint (±10 %) using a reference

measurement.

Pre-conditions for actions:

@

The salt content of the sample water is close to the setpoint; the

sampling station is in operation.

@

A hand-held measuring device is available.

Perform the following work steps:

1.

Working in the main menu under “Calibration”, navigate to the “Sen-

sors” tab.

2.

Working under “Sensor”, select the sensor that measures the con-

ductivity and which you wish to calibrate.

3.

Press the “1 points” button.

4

The calibration starts.

4.

Remove the sample water from the measuring point.

5.

Determine the conductivity with the portable meter.

6.

Enter the value ascertained using the measuring device.

7.

Confirm the entry with the green checkmark.

ü

The calibration of the conductivity in the setpoint has been

completed.

9.5.6 Temperature

You can connect a temperature sensor to every input module. You can ad-

just the temperature sensor by setting a reference value.

When setting the reference value, the device will automatically correct

the measurement of the temperature sensor by the difference.

9.5.6.1 Adjustment of a temperature sensor

Pre-conditions for actions:

ü

A thermometer is available.

ü

You have activated the measurement of the temperature (see section

8.3.1.2 „Temperature inputs“ on page 30).

Perform the following work steps:

1.

Working in the Main menu under “Calibration”, navigate to the “Tem-

perature” tab.

2.

Working under “input”, select the input module for which you wish to

set a reference value.

3.

Press the “Reference value” button.

4.

Enter the reference temperature measured beforehand.

5.

Confirm with the green checkmark.

ü

Adjustment of a temperature sensor completed.

9.5.7 Servomotor relay

9.5.7.1 Servomotor with position feedback

You can connect servomotors with a position feedback to your device and

control them via an output. Before you can control the servomotor exact-

ly, you must first compensate the control via your device and the position

of the servomotor.

During compensation, the servomotor is first driven to the end position

and then back.

This section only applies to servomotors with a feedback potentiometer.

9.5.7.2 Calibration of an servomotor with position feedback

Pre-conditions for actions:

ü

The servomotor is switched on and has been connected properly.

ü

The output has been configured correctly (see Tab. 20 „Functions of

the individual controllers“ on page 17).