1

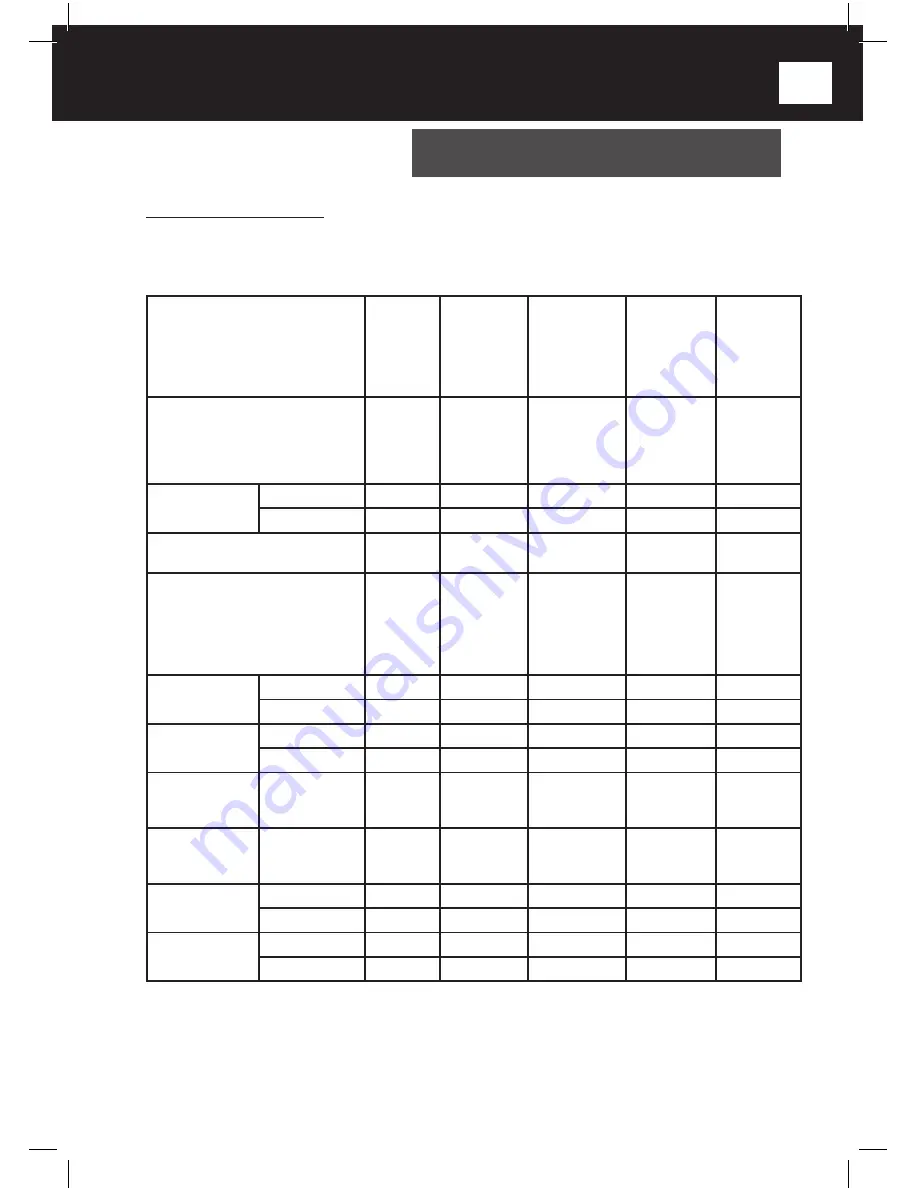

8.1 Maintenance scheme

To avoid damages and to ensure the proper function of all safety devices, these maintenance

works should be carried out with regular intervals. Disregarding the maintenance may cause

risk of accidents!

Action

Every

day

before

operation

After first

20 H. of

operation

Every 2nd

week or

50 H.

Every

month or

100 H.

Every year

or 300 H.

Check the fuel tank:

-

Filling

-

Tightness

-

Pipes

-

Tank cap

X

Air filter

Check/clean

X

Replace

X

Binding screws/bolts:

Check for proper pulling

X

External items (proper pulling):

- Gas lever

- Motor brackets

- Belt protection

- Central brackets

- Agitator/plate (connection)

X

Motor oil

Check

X

Replace

X

1

X

Belt

Check/adjust

X

Replace

X

Lubrication of

brackets for

steering shackle

X

Clean collecting

container for fuel

sediments

X

Spark plug

Check/clean

X

Replace

X

Oil in agitator

Check

X

Replace

X

1

After first operation event

MAINTENANCE

GB

RP-110HP_manual_GB.indd 19

04.02.2010 09:23:03

Содержание RP-110HP

Страница 4: ...4 6 7 8 5 5 4 9 1 3 4 RP 110HP_manual_GB indd 4 04 02 2010 09 22 48...

Страница 5: ...5 9 10 2 4 11 12 9 1 13 5 RP 110HP_manual_GB indd 5 04 02 2010 09 22 48...

Страница 28: ...28 13 PARTS INCLUDED Motor unit PARTS INCLUDED RP 110HP_manual_GB indd 28 04 02 2010 09 23 05...

Страница 29: ...29 GB Agitator PARTS INCLUDED RP 110HP_manual_GB indd 29 04 02 2010 09 23 05...

Страница 31: ...31 GB RP 110HP_manual_GB indd 31 04 02 2010 09 23 06...