Doc: I437GB04_16.docx 09/03/2016

p. 14 / 37

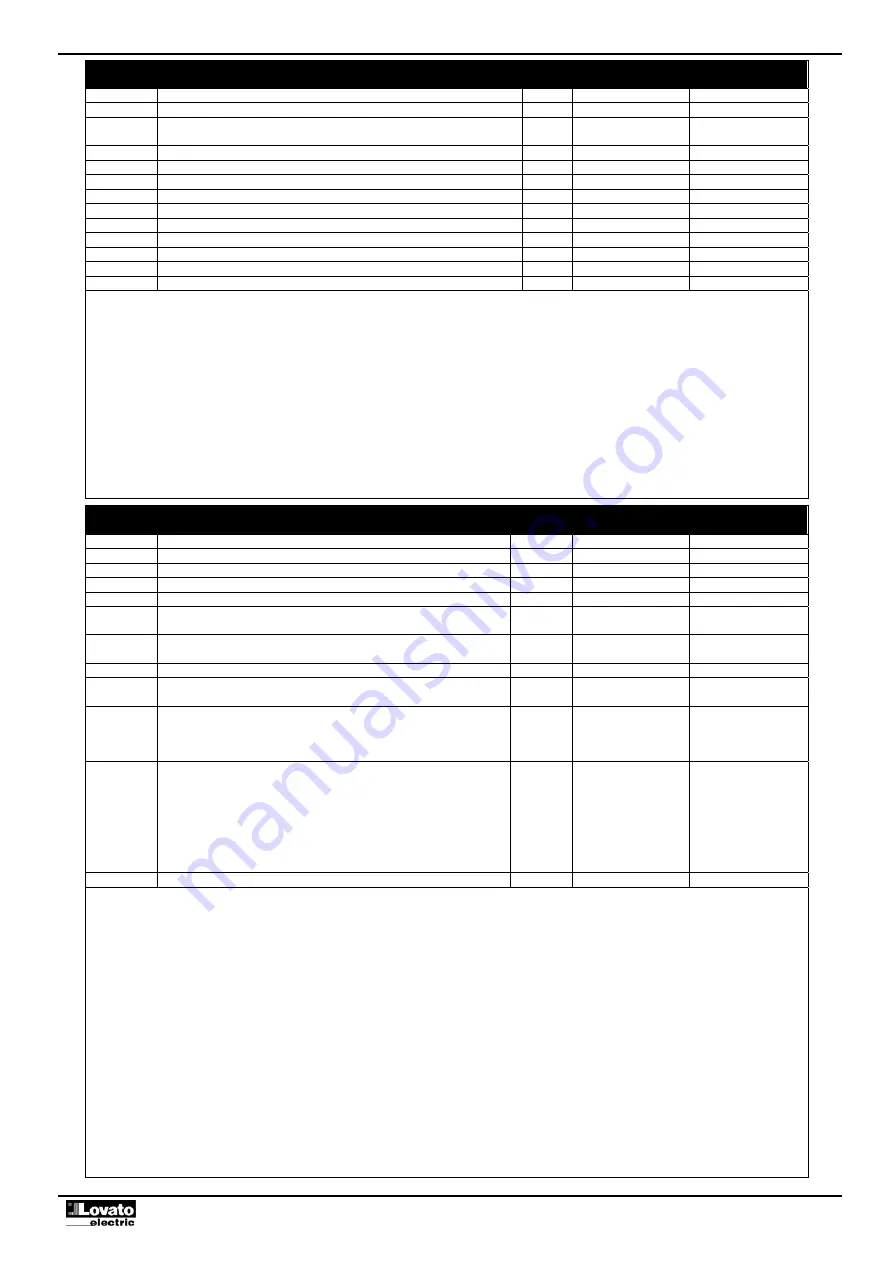

M06 - SOURCE LINES

(SRCx, n=1…3)

Unit

Default

Range

P06.n.01

Source description

SRCx (char*6)

P06.n.02

Signal priority

n 1

– 3

P06.n.03

SRCx source type

Mains Mains

Genset

P06.n.04

Genset cooling time

sec

120

1-3600

P06.n.05

Rated source power

kW

1000 1-100000

P06.n.06

Max. power use limit

%

OFF

OFF / 1-200

P06.n.07

Max. power use delay

sec

60 1

- 9999

P06.n.08

Power use return limit

%

OFF

OFF / 1-200

P06.n.09

Power use return delay

sec

60 1

- 9999

P06.n.10

Power use max. limit for non-priority load disconnection

%

OFF

OFF / 1-200

P06.n.11

Power use max. delay for non-priority load disconnection

sec

60 1

- 9999

P06.n.12

Power use return limit for non-priority load connection

%

OFF

OFF / 1-200

P06.n.13

Power use return delay for non-priority load connection

sec

60 1

- 9999

Note: This menu is divided into 3 sections for source lines SRC1..3.

P06.n.01

- Alphanumeric description on the respective power source line which will be shown on the display synoptic panel.

P06.n.02

- Power line priority. In case of simultaneous presence of multiple power lines on the same load, the one with priority 1 is connected. If the line with priority

1 is not present, the one with priority 2 is used etc. If two sources are programmed with the same priority, the software attribute higher priority to the one

most on the left.

P06.n.03

- This defines the type of power source of the SRCx line.

Mains

= The mains symbols is shown on the synoptic panel.

Genset

= The genset symbol is

shown and the start/stop outputs are managed; is sought.

P06.n.04

- Maximum cooling cycle time. Example: time which elapses between the load disconnection of the genset and the actual stopping of the engine.

P06.n.05

- Max. rated power available on the SRCx source.

P06.n.06

- Max. power limit (in percentage) which can be taken from the SRCx line. If this limit is exceeded by the load, the load is transferred onto another source

line.

P06.n.07

- Delay referred to the previous parameter.

P06.n.08

- Power value (in percentage) which defines the hysteresis with respect to P06.n.06 for the load return to SRCx.

P06.n.09

- Delay referred to the previous parameter.

P06.n.10

-

P06.n.11 - P06.n.12 - P06.n.13

- Thresholds and delays which define the power levels for connecting and disconnecting the non-priority load.

M07 - BREAKERS

(BRKn, n=1…3)

Unit

Default

Range

P07.n.01

Breaker description

BRKn (char*6)

P07.n.02

Interlock time SRCx

…

sec

6.0

0.1…1800.0

P07.n.03

Breaker operation max. time (alarm delay A03 and A04)

sec

5

1…900

P07.n.04

Open pulse time

sec

10 0-600

P07.n.05

Close pulse time

sec

1 0-600

P07.n.06

Continuous control in RESET/OFF mode

NOC OFF

NOC

P07.n.07

Breaker following no closing (with feedback open only)

OFF OFF

ON

P07.n.08

Minimum coil opening pulse time

sec

1.0

0.1 … 10.0

P07.n.09

Delay between min. coils and spring load

sec

0.2

0.1 … 10.0

P07.n.10

Closing retry

AUT OFF

AUT

AUT+MAN

CLOSING

P07.n.11

Breaker conditional enable

OFF OFF

INPx

OUTx

LIMx

REMx

PLCx

Ax

UAx

P07.n.12

Function index (x)

OFF

OFF / 1…99

Note: This menu is divided into 3 sections for controlling the source line breakers BRK1..3.

P07.n.01 -

Alphanumeric description which identifies the line breaker on the display synoptic panel.

P07.n.02 -

Interlock time from the opening instant of the breaker BRKn to the closing of another breaker.

P07.n.03 -

Timeout between sending of a control from a line breaker and the actual execution of the operation. After having sent an opening or closing control to

the breaker, alarms A03 or A04 are generated if it is not positioned correctly before the timeout. It works when the auxiliary state contacts of the

breakers is programmed and wired.

P07.n.04 -

Minimum opening control time, when the breaker control is defined by means of a pulse (P08.01 = Pulse breaker). For applications with motorised line

breakers, this must be set to a sufficient time to allow complete charging of the springs. This time is considered also when working in continuous control

mode.

P07.n.05 -

Closing control pulse time.

P07.n.06 –

Otherwise, the breaker control is selected as continuous (P08.01 = Continuous breaker), defines the behaviour of the board when it switches to the OFF

operating mode.

OFF

= The control relays are de-energised.

NOC

= The control relays remain in in their original state (No Change).

P07.n.07 -

In case of timeout caused by the line breaker BRKn failing to close (open feedback contact) causes the transfer of the load on an alternative line.

P07.n.08 -

Minimum coil deactivation pulse duration for breaker opening pulse.

P07.n.09

- Time elapsed between minimum voltage opening pulse and breaker spring loading control.

P07.n.10

- This defines whether in case of failure to close the ATL900 must perform a retry consisting of a cycle of opening/spring recharging cycles followed by a

new closing attempt. The failed closing alarm will be generated if the second attempt also fails.

OFF

= Closing is not retryed.

AUT

= Retry is manual only.

AUT+MAN

= Retry enabled in both modes.

CLOSING

= Closing retry is executed in AUT or MAN only in case of failed closing

but not when breaker opens unexpectedly.

P07.n.11, P07.n.12

- Conditional enable of breaker.

OFF

= Breaker is enabled normally.

(Any other setting)

= The breaker is enabled only if the selected variable

is active. When the variable is not active, if the breaker is open, its closing will be avoided. If the breaker is closed, it will be opened.