INSTALLATIoN

WH45P

23

/42

rev 20-10

3.12.

Installations within floor

Refer to the section Construction supports characteristi-

cs p. 16 for further information.

Comply with the minimum distances indicated on section

Minimum distances p. 14.

before and after installation please perform a functional

test. Refer to section Mechanism type for further informa-

tion p. 7.

3.12.1.

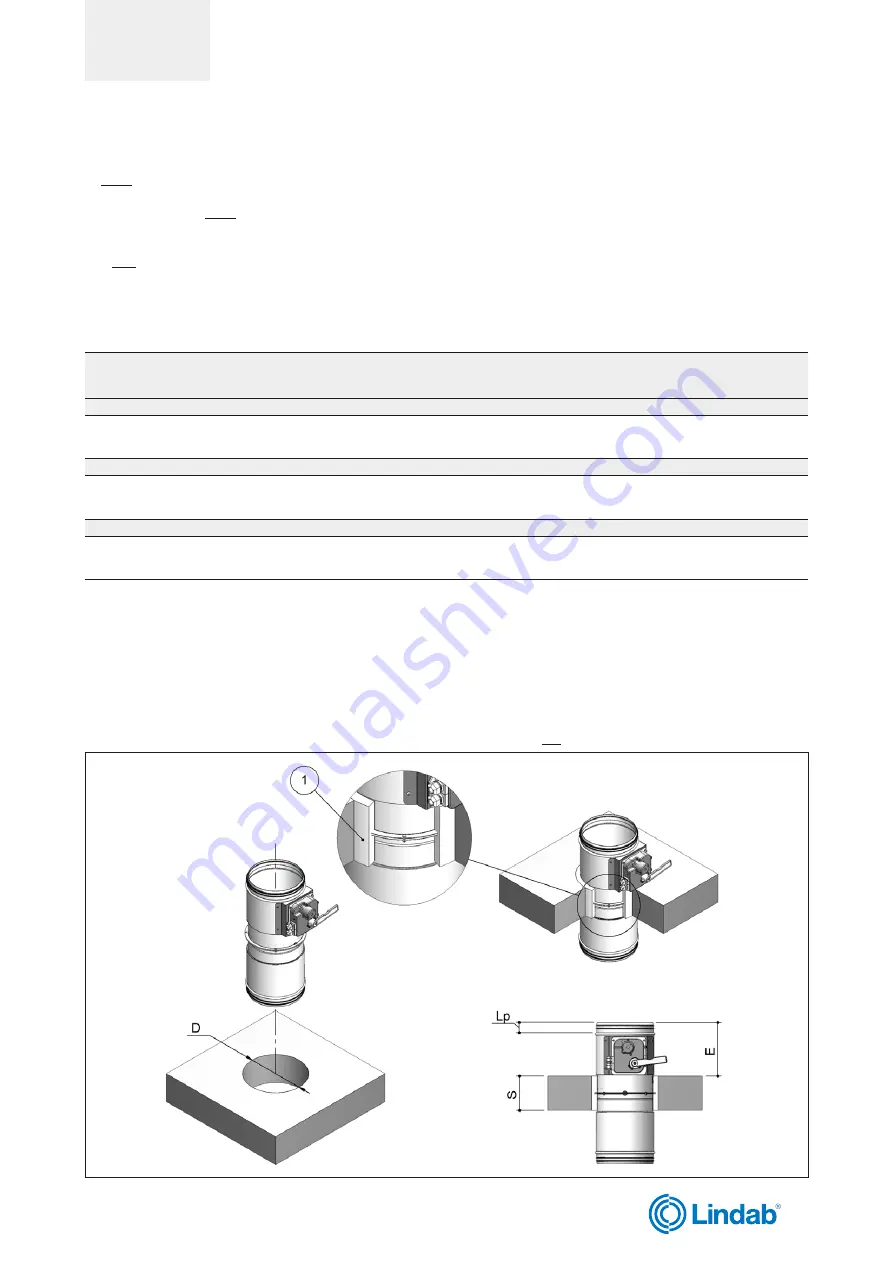

Floor opening

A opening must be provided in the floor as indicated in the

table and in the drawing

3.12.2.

Damper positioning

Position the damper in the opening so that the side of the

closing mechanism extends as indicated in the table and

in the drawing.

Close the blade before installing the fire damper.

3.12.3.

Filling

Fill the space between the floor and the damper as indica-

ted in the table and in the drawing.

Sealing with concrete is not allowed.

Fire resistance classi-

fication

“D” hole size

[mm]

Damper protrusion

from the floor “E”

[mm]

Floor minimum

thickness “S”

[mm]

Sealing

EI 90 S Installation within floor

Floor minimum density 650 kg/m³

EI 90 S

(500 Pa)

From Ø + 40

to Ø + 55

(circular hole)

215 + Lp

100

Mortar sealing

EI 120 S Installation within floor

Floor minimum density 650 kg/m³

EI 120 S

(500 Pa)

From Ø + 40

to Ø + 55

(circular hole)

190 + Lp

150

Mortar sealing

EI 180 S Installation within floor

Floor minimum density 2200 kg/m³

EI 180 S

(500 Pa)

From Ø + 40

to Ø + 55

(circular hole)

190 + Lp

150

Mortar sealing

1.

Mortar M-10, EN998-2

D

Hole size: see table above

S

Floor minimum thickness: see table above

E

Damper protrusion from the floor: see table above

Lp

Overlap length between fire damper and duct: see section

Dimension p. 9

WH45P

23

We reserve the right to make changes without prior notice