Leuze electronic GmbH + Co. KG

In der Braike 1 D-73277 Owen

We reserve the right to make changes

[email protected] • www.leuze.com

Tel. +49 (0) 7021 573-0

03/2020 - 50134631-02 - 4/20

MSI-SR-2H1-xx

Original operating instructions

Evaluation unit for two-hand control devices

•

Basic unit according to ISO 13851:2019 type IIIA, EN 60204-1 and

EN ISO 13849-1:2015

•

PL c / category 1 according to EN ISO 13849-1

•

SIL CL 1 according to DIN EN 62061

•

Single-channel control for 1 NO contact and 1 NC contact

•

Monitoring of synchronous operation

•

1 enabling current path and 1 current signalling path (changeover contact)

Device versions

MSI-SR-2H1-01 with screw terminals, pluggable

MSI-SR-2H1-03 with spring-loaded terminals, pluggable

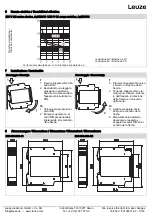

Front view

SUPPLY

K1

LED green, status indicator for power supply

LED green, status indicator for relay K1

Safety Regulations

•

Installation, commissioning, modification and retrofitting must

only be performed by a qualified electrician.

•

Disconnect the device/the system from the power supply

before starting work. In the case of installation and system

errors, mains voltage can be present on the control circuit in

the case of non-galvanically isolated devices.

•

Observe the electrotechnical and professional trade

association safety regulations for installation of the

equipment.

•

Opening the case or other manipulation voids any warranty.

•

In the case of improper use or any use other than for the

intended purpose, the device must no longer be used and any

warranty claim is void. Invalidating causes can be: strong

mechanical loading of the device, such as occur when falling

or voltages, currents, temperatures, humidity outside the

specifications.

•

Always check all safety functions in accordance with the

applicable regulations during initial commissioning of your

machine/system and observe the specified inspection cycles

for safety devices.

Attention

•

Take the following safety precautions before starting

installation/assembly or dismantling:

1.

Disconnect the device/the system from the power supply

before starting work.

2.

Secure the machine/system against being switched on again.

3.

Confirm that no voltage is present.

4.

Ground the phases and short to ground briefly.

5.

Cover and shield neighbouring live parts.

6.

The devices must be installed in a switch cabinet with a

protection class of at least IP 54.

•

Limited contact protection!

−

Protection class according to EN 60529: IP 20.

−

Finger-proof according to EN 50247.

1

Proper use

The unit can be used with machines which require per-

sonnel to reach into the danger zone repeatedly during

operation.

Only use the unit in accordance with its intended pur-

pose. Pay particular attention to the information in the

technical data.

2

Function

The safety requirements of the unit are grouped under

Type IIIA according to ISO 13851:2019. The safety

behaviour is designed for Category 1 applications

(EN ISO 13849-1). The synchronous activation of the

two two-hand pushbuttons or safety door contacts is

monitored. Each of the two pushbuttons is connected to

the unit via an NO contact and an NC contact. The tech-

nical design of the input circuit makes provision for moni-

toring for cross-circuits and short-circuits to earth. The

output function is designed with 1 NO contact as ena-

bling current paths and 1 NC contact as messaging

current path.

Once the supply voltage has been applied to terminals

A1/A2, the enabling current paths close when the two-

hand pushbuttons (T1 + T2) are pressed at the same

time. The two pushbuttons must be pressed synchro-

nously in less than 500 ms in order for the unit to be

enabled. Even releasing just one of the two pushbuttons

will de-energise the unit (due to the enabling current path

opening). The unit can only be restarted once both two-

hand pushbuttons have moved back to their initial posi-

tion (e.g. have been released). The current status of the

unit is indicated by 2 LEDs. The application of the supply

voltage is indicated by the SUPPLY LED and the activa-

tion of the two pushbuttons is indicated by the K1 LED.