Page 19

Unit Start−Up & Adjustments

Before starting unit, make sure the oil tank is adequately

filled with clean No. 1 or No. 2 furnace oil.

NOTE − Water, rust or other contaminants in oil supply sys-

tem will cause malfunction and failure of the internal parts

of the fuel pump.

CAUTION

Never burn garbage or paper in the heating system.

Never leave papers near or around the unit.

CAUTION

Blower access door must be in place before start-up.

Burner Start−Up

1 − Set thermostat for heating demand and turn on electri-

cal supply to unit.

2 − Open all shut−off valves in the oil supply line to the

burner.

3 − While the ignition is on, press and release the reset

button on the burner control (hold 1/2 second or less).

4 − Bleed the pump until all froth and bubbles are purged.

The bleed port is located on the bottom of the fuel

pump. To bleed, attach a clear plastic hose over the

vent plug. Loosen the plug and catch the oil in an

empty container. Tighten the plug when all the air has

been purged.

NOTE − A two−line fuel system will normally bleed itself

by forcing air back to the tank through the return line.

This type of bleeding procedure is not necessary.

5 − If burner fails to start within the set time, the burner

control will lock out operation. Press the reset button

to reset the control as in step 3. See figure on page 3

for burner parts arrangement.

CAUTION

Do not push the reset button on the primary control

more than one time.

6 − Repeat steps 4 and 5, if necessary, until pump is fully

primed and oil is free of bubbles. Then, terminate the

call for heat. The burner control will resume normal

operation

Fuel Pump Pressure Adjustment

Measure fuel pump pressure with unit off. Attach pressure

gauge to pump outlet. Turn unit on and check pressure and

compare to table 9. Adjust if necessary.

Temperature Rise Adjustment

To measure temperature rise, place plenum thermometers

in warm air and return air plenums. Locate thermometer in

warm air plenum where thermometer will not see" the heat

exchanger to prevent it from picking up radiant heat. Set

thermostat to its highest setting to start unit. After plenum

thermometers have reached their highest and steadiest

readings, subtract the readings. The difference in temper-

atures in the supply and return air plenums should approxi-

mate the temperatures listed in table 8 and on the ap-

pliance rating plate.

If the temperature rise is not within the range listed, check

the following items:

D

Make sure that properly sized nozzle has been

used (table 9).

D

Make sure that fuel pump pressure is correct.

D

If furnace is in cutback mode, check for:

Dirty filters,

Dirty indoor coil,

Restricted ducts, closed registers, etc.

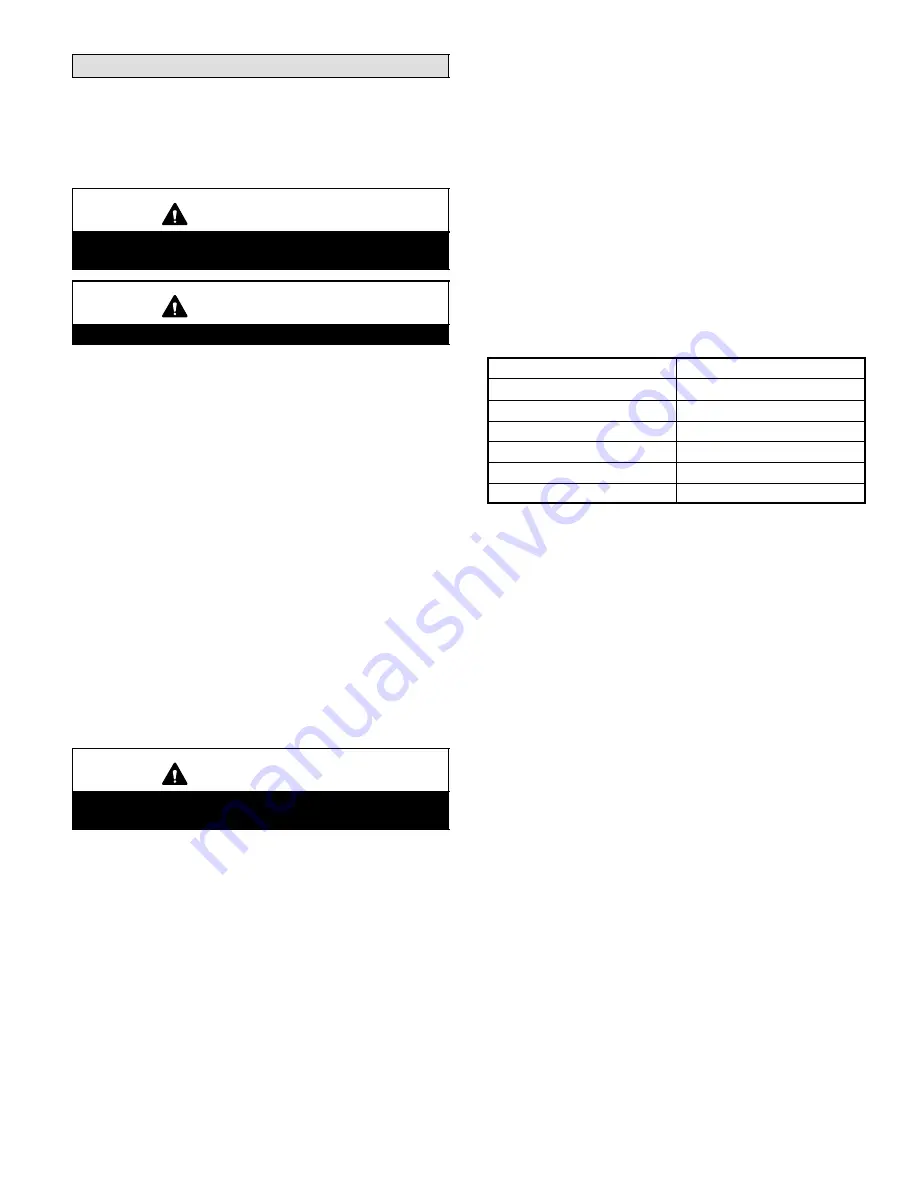

Table 8

Temperature Rise

Unit

Temperature Rise °F

SLO183UFV68

50 − 80

SLO183UFV86

50 − 80

SLO183UFV101

65 − 75

SLO183UFV114

70 − 80

SLO183UFV135

65 − 75

SLO183UFV150

70 − 80

Limit Control

Limit Control Do not adjust from factory setting.

Burner Adjustment

The following instructions are essential to the proper op-

eration of SLO183UFV series oil furnaces. To prevent

sooting, these instructions must be followed in sequence:

1.

Draft

This test should be taken at the breach be-

tween the outlet of the vent connector and the baro-

metric draft control. Generally a 1/4" hole will need to

be drilled for the draft gauge to be inserted into the vent

connector.

A minimum of 0.03 draft must be established without

the burner in operation. With the burner in operation,

the draft should be 0.04 to 0.05. This is VERY critical to

the flame retention head burners.

Oil furnace installations also require careful inspection

to make sure the chimney is in good shape and can ac-

commodate the products of combustion. The temper-

ature in the unconditioned space will also affect the

draft if long vent connectors are allowed to get too

cold.

2.

Overfire Draft

This test should be taken with the

burner in operation. Remove the plug from the center

of the inspection port. Insert your draft gauge into the

hole.

A reading of the overfire draft should be 0.02 less than

the reading found in the vent connector. If a positive

reading is seen at this point, the combustion fan is

pumping too much air into the heat exchanger. Make

the necessary adjustments with the air shutter or air

band.