7

cavity when rigid pipe is used. Ensure that a sediment trap is installed

upstream of the heater (figure 4) within the structure’s piping system to

prevent moisture and contaminants from passing through the pipe to

the heater controls and burner. Failure to do so could prevent the heater

from operating reliably.

The heater gas inlet connection is 3/8” NPT at the regulator, located

below the burner, in the right hand side of the heater. When tightening

up the joint to the regulator hold the regulator securely with a wrench to

prevent the regulator from moving.

Turn on gas supply and test for gas leaks using a gas leak test solution

(also referred to as bubble leak solution).

NOTE: using a soapy water solution (50% dish soap, 50% water) is an

effective leak test solution, but it is not recommended, because the

soap residue that is left on the pipes/fittings can result in corrosion over

time.

A.

Light the appliance (refer to the lighting instructions label in the con-

trol compartment or on page 10).

B.

Brush all joints and connections with the gas leak test solution to

check for leaks. If bubbles are formed, or gas odor is detected, turn the

gas control knob (off/pilot/on) to the “OFF” position. Either tighten or

refasten the leaking connection, then retest as described above.

C.

When the gas lines are tested and leak free, be sure to rinse off the

leak testing solution.

D.

Observe the individual tongues of flame on the burner. Make sure all

ports are open and producing flame evenly across the burner. If any

ports are blocked, or partially blocked, clean out the ports.

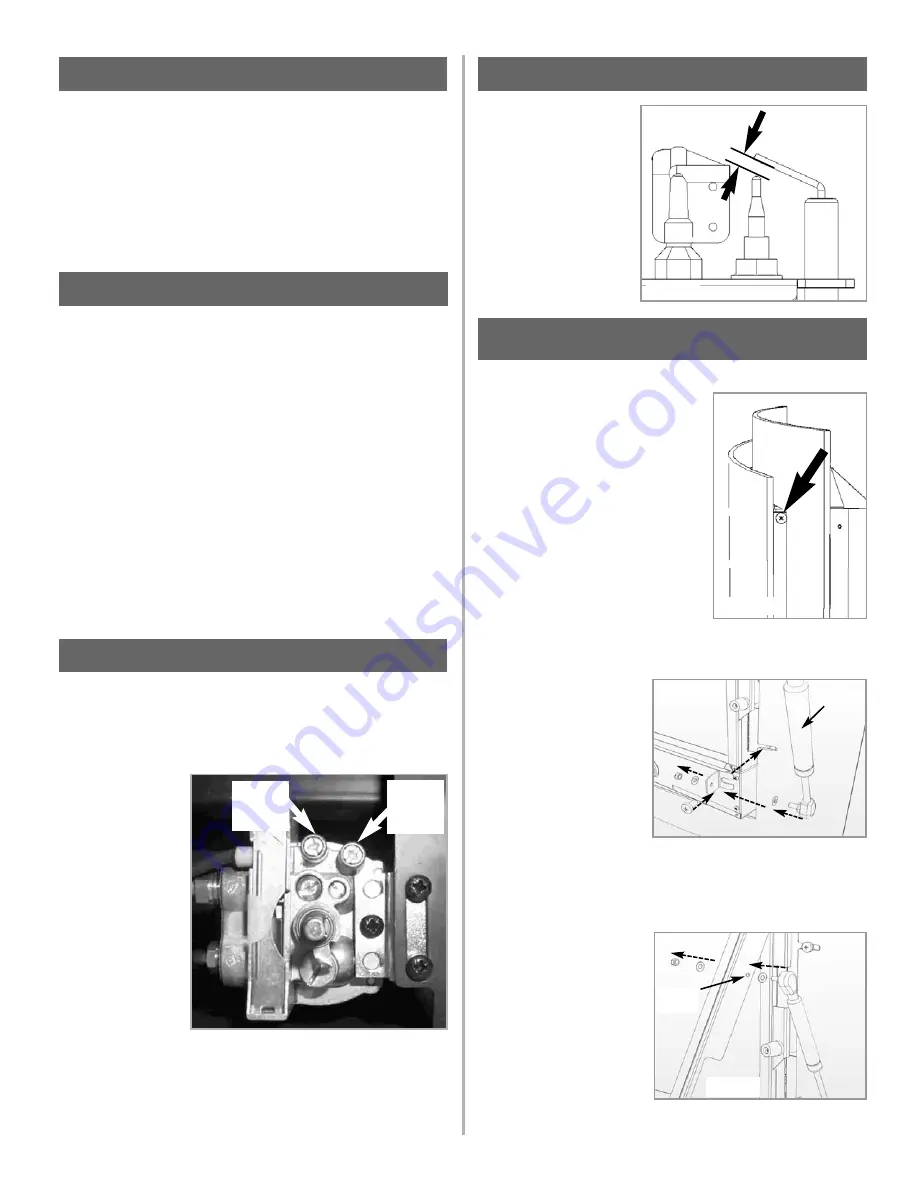

The heater regulator controls the burner pressure which should be

checked at the pressure test points located on the control valve itself

(shown in figure 5) for burner (manifold) and regulator setting pressure.

The valve is found on the centre of the appliance behind the valve

cover. Remove the

cover plate by

unscrewing the four

retaining screws.

Release the test

point screws and

ensure operating

pressures are as

specified in section 3

“Appliance data” on

page 2 of these

instructions.The

pressure should be

checked with the gas

heater burning and

the control set to high flame.

The pressure regulator on manual models is preset and locked to avoid

tampering. If the pressure is not as specified in the Appliance Data sec-

tion on page 2, replace the regulator with P/N H6063. Replace the test

point screws after pressure measurement ensuring no gas leaks.

The gap between the

spark electrode and the

pilot should be 1/8” to

3/16” to produce a good

spark. There should be no

need to adjust this. If

under any circumstances

the piezo electric spark

fails, the pilot cannot be lit

manually.

The glass panel is supported by two

self-locking M6 screws, one on each

side of the fire. The glass panel must be

held in position while the screws are

inserted on each side - it is

recommended to seek assistance for

this operation. See figure 6a. The

screws should be screwed in fully and

then undone one turn to allow the glass

panel to swing open for access to the

controls.

The appliance features a piston damper

hinge assembly. The damper assembly

should be fitted onto the rear of the

glass facia, on the lower right hand side

as follows:

1) Ensure that the piston

portion of the damper is

positioned as shown in

figure 6b. Remove the

Philips screw securing the

frame, and fit the lower

piston bracket to the frame

and fully re-tighten the

screw.

Now fit the lower piston bolt

through the hole in the bracket, with the two nylon washers positioned

either side of the bracket. Finally, attach the “nyloc nut” to the damper

thread, tighten and then release one quarter turn. Check that the

assembly can swivel.

2) The damper top fixing is

shown in figure 6c. Locate

the fixing hole in the glass

window bracket. Place a

nylon washer each side of

the bracket, and affix the

damper bolt using the “nyloc

nut” provided. Tighten the

nut and release one quarter

turn. Finally check operation of damper from the fully open to fully

closed positions.

12.0 CHECKING THE GAS CONNECTIONS

13.0 GAS PRESSURE CHECK

Burner

(Manifold)

pressure

Regulator

pressure

setting

Figure 5

14.0 SPARK GAP

Figure 6

Spark gap

15.0 FITTING THE GLASS FACIA

11.0 CONNECTING A GAS LINE - continued

Damper

Fixing

hole

Figure 6a

Figure 6b

Figure 6c