-7-

www.igmtools.com

up the workpiece and cause kickback when the

saw is restarted.

• Keep saw blades clean, sharp, and with

sufficient set. Never use warped saw blades or

saw blades with cracked or broken teeth. Sharp

and properly set saw blades minimise binding,

stalling and kickback.

4.8 Table saw operating procedure warnings

• Turn off the table saw and disconnect the

power cord when removing the table insert,

changing the saw blade or making adjustments

to the riving knife or saw blade guard,

and when the machine is left unattended.

Precautionary measures will avoid accidents.

• Never leave the table saw running

unattended. Turn it off and don’t leave the

tool until it comes to a complete stop. An

unattended running saw is an uncontrolled

hazard.

• Locate the table saw in a well-lit and level

area where you can maintain good footing and

balance. It should be installed in an area that

provides enough room to easily handle the size

of your workpiece. Cramped, dark areas, and

uneven slippery floors invite accidents.

• Frequently clean and remove sawdust from

under the saw table and/or the dust collection

device. Accumulated sawdust is combustible

and may self-ignite.

• The table saw must be secured. A table saw

that is not properly secured may move or tip

over.

• Remove tools, wood scraps, etc. From

the table before the table saw is turned

on. Distraction or a potential jam can be

dangerous.

• Always use saw blades with correct size and

shape (diamond versus round) of arbour holes.

Saw blades that do not match the mounting

hardware of the saw will run off-centre, causing

loss of control.

• Never use damaged or incorrect saw blade

mounting means such as flanges, saw blade

washers, bolts or nuts. These mounting means

were specially designed for your saw, for safe

operation and optimum performance.

• Never stand on the table saw, do not use

it as a stepping stool. Serious injury could

occur if the tool is tipped or if the cutting tool is

accidentally contacted.

• Make sure that the saw blade is installed

to rotate in the proper direction. Do not use

grinding wheels, wire brushes, or abrasive

wheels on a table saw. Improper saw

blade installation or use of accessories not

recommended may cause serious injury.

4.9 Electrical

• Machine plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

• Disconnect the power first. Always disconnect

machine from power supply before adjusting,

changing tooling, or servicing machine.

• Power supply: 230V/50Hz/1 phase.

• Use a qualified electrician for all electrical

connections. Failure to do so may result in

damage to the tool and electrical shock to the

operator and bystanders.

• Power plugs. Your machine may not come

with a power plug because of the variance

in power receptacles. Consult with a local

electrician prior to purchasing a power plug.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• Extension cords. Consult with or use a

qualified electrician prior to sizing extension

cords for use with this machine.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a residual current device (rcd)

protected supply.

• Electrical protection. End user should connect

the machine to a circuit protected with a 16 A

circuit breaker, tripping characteristic C (16/1/C)

and overvoltage protection.

4.10 Noise emissions

•

Reference standards.

The measurements of noise emission were

conducted according to the EN ISO 11202:2010

for the determination of sound pressure level

at the operation positions. When the measured

sound pressure levels at the operation positions

exceed 80db(a), the measurements of sound

power levels were conducted according to EN

ISO 3746:2010.

•

Operating conditions.

The operating conditions for noise

measurement comply with Annex A of ISO

7960:1995.

•

Testing results:

A-weighted Sound Pressure - Level 91.3 dB

A-weighted Sound Power - Level 113.8 dB

Associated uncertainty - K=4dB

Background noise of measurement surrounding

is - 55dB

The figures quoted are emission levels and

are not necessarily safe working levels. Whilst

there is a correlation between the emission

and exposure levels, this cannot be used

reliably to determine whether or not further

precautions are required. Factors that influence

the actual level of exposure of the workforce

include the characteristics of the work room, the

other sources of noise etc. i.e. the number of

machines and other adjacent processes. Also

the permissible exposure level can vary from

country to country. This information, however,

will enable the user of the machine to make a

better evaluation of the hazard and risk.

4.11 Grounding

• Proper grounding of your machines lowers the

risk of injury by electricity.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

• Do not modify the plug. Do not remove any of

the prongs attached to the proper plug for the

machine.

• Use only 3-wire extension cords.

Some extension cords only have two wires,

which does not allow for grounding.

• Always use grounded connections and work

only on a grounded circuit.

4.12 Rulings

Warning: Before connecting this tool to a

power supply (receptacle, outlet, etc.) Make

sure that the voltage supplied is the same

that is specified on the nameplate of the tool.

Also make sure that the power supply is

equipped with the appropriate breaker and

plug according to your local electrical code. If

in doubt, do not plug in the machine. Using this

tool with a voltage different than that stated

on the nameplate can damage the electrical

components of this machine and any such

damage will not be covered by a warranty.

Warning: Some dust created by power sanding,

sawing, grinding, drilling and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paint.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk of exposure varies, depending on how

often you do this type of work. To reduce your

exposure to these chemicals, work in a well-

ventilated area and work with approved safety

equipment, such as face or dust masks that are

specifically designed to filter out microscopic

particles.

4.13 Notice on safe use

The machinery sold by Laguna Tools,

distributed by IGM Tools and machinery co.,

are safe when used properly and comply to

with the CE norms, standards and regulations

for safe use. Laguna Tools or IGM is in no

way responsible for injury or death that occurs

while using this product. Your personal safety is

100% your responsibility and using this product

requires 100% of your attention.

If there is any concern related to the application

you are intending to use this tool for, DO NOT

proceed until you have contacted the retailer

you purchased it from and have been advised

on the correct application of the product.

This manual is intended to thoroughly cover

the setup up, maintenance, and proper

adjustments of your new purchase. Aside from

the proceeding general safety considerations,

this manual DOES NOT cover woodworking

or metalworking techniques that are possible

with this product and the appropriate safety

precautions necessary for safe practices. There

are several organizations with published safe

practices, techniques, and proper operation of

this tool.

Warning

The symbols below advise that you

follow the correct safety procedures when using

this machine.

Keep your fingers away from the

saw blade

Environmental protection:

Waste electrical products should not

be disposed of with household waste.

Please recycle where facilities exist.

Check with your local Authority or retailer for

recycling advice.

Содержание Fusion2 2022

Страница 2: ...2 www igmtools com...

Страница 3: ...3 www igmtools com...

Страница 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Страница 19: ...19 www igmtools com Fence assembly...

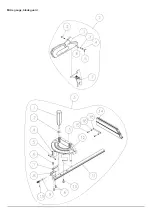

Страница 20: ...20 www igmtools com Mitre gauge blade guard...

Страница 21: ...21 www igmtools com Motor and trunnion...

Страница 22: ...22 www igmtools com Cabinet...