-6-

www.igmtools.com

• Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

• Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

• Maintain power tools and accessories. check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation. If

damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

• Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

• Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow

for safe handling and control of the tool in

unexpected situations.

• Use proper speed. A machine will do a better

and safer job when operated at the proper

speed.

• Use the correct tool for the job. Know

the limitations and capabilities of your new

purchase. Do not try to “fit a square peg in a

round hole.

• Secure the work piece. For all woodworking

and metalworking applications, the workpiece

should be secured correctly by the operator

using appropriate clamps and vises. Always

use a clamp or vise when available — it is safer

than using your hands.

• Feed direction. If feed rate is applicable, then

there is only one direction of feed rate for the

tool. Do not force the workpiece in the wrong

feed direction.

• Never leave tool running unattended. Do not

leave the tool until it comes to a complete stop.

When unattended, unplug the tool.

• Maintain tools with care. Keep cutting

tools sharp and clean for better and safer

performance.

• Follow instruction for lubricating and changing

accessories. Inspect tool cords periodically

and if damaged have then repaired by an

authorized service facility. Inspect extension

cords periodically and replace if damaged.

Keep hand dry, clean and free from oil and

grease.

• Illumination. Adequate general or localized

lighting shall be provided.

• Dust Collection. During use the saw benches

shall be connected to an external chip and dust

extraction system.

4.5 Guarding related warnings

• Keep guards in place. Guards must be in

working order and be properly mounted.

A guard that is loose, damaged, or is not

functioning correctly must be repaired or

replaced.

• Always use saw blade guard and riving

knife for every through–cutting operation. For

through-cutting operations where the saw blade

cuts completely through the thickness of the

workpiece, the guard and other safety devices

help reduce the risk of injury.

• Make sure the saw blade is not contacting

the guard, riving knife or the workpiece before

the switch is turned on. Inadvertent contact of

these items with the saw blade could cause a

hazardous condition.

• Adjust the riving knife as described in

this instruction manual. Incorrect spacing,

positioning and alignment can make the riving

knife ineffective in reducing the likelihood of

kickback.

• For the riving knife to work, it must be

engaged in the workpiece. The riving knife is

ineffective when cutting workpieces that are

too short to be engaged with the riving knife.

Under these conditions a kickback cannot be

prevented by the riving knife.

• Use the appropriate saw blade for the riving

knife. For the riving knife to function properly,

the saw blade diameter must match the

appropriate riving knife and the body of the saw

blade must be thinner than the thickness of

the riving knife and the cutting width of the saw

blade must be wider than the thickness of the

riving knife.

4.6 Work related warnings

• Danger: never place your fingers or hands

in the vicinity or in line with the saw blade. A

moment of inattention or a slip could direct

your hand towards the saw blade and result in

serious personal injury.

• Feed the workpiece into the saw blade or

cutter only against the direction of rotation.

Feeding the workpiece in the same direction

that the saw blade is rotating above the table

may result in the workpiece, and your hand,

being pulled into the saw blade.

• Never use the mitre gauge to feed the

workpiece when ripping and do not use the rip

fence as a length stop when cross cutting with

the mitre gauge. Guiding the workpiece with the

rip fence and the mitre gauge at the same time

increases the likelihood of saw blade binding

and kickback.

• When ripping, always apply the workpiece

feeding force between the fence and the saw

blade. Use a push stick when the distance

between the fence and the saw blade is less

than 150 mm, and use a push block when this

distance is less than 50 mm. Work helping

devices will keep your hand at a safe distance

from the saw blade.

• Use only the push stick provided by the

manufacturer or constructed in accordance

with the instructions. This push stick provides

sufficient distance of the hand from the saw

blade.

• Never use a damaged or cut push stick. A

damaged push stick may break causing your

hand to slip into the saw blade.

• Do not perform any operation “freehand”.

Always use either the rip fence or the mitre

gauge to position and guide the workpiece.

“Freehand” means using your hands to support

or guide the workpiece, in lieu of a rip fence

or mitre gauge. Freehand sawing leads to

misalignment, binding and kickback.

• Never reach around or over a rotating saw

blade. Reaching for a workpiece may lead to

accidental contact with the moving saw blade.

• Provide auxiliary workpiece support to the

rear and/or sides of the saw table for long and/

or wide workpieces to keep them level. A long

and/or wide workpiece has a tendency to pivot

on the table’s edge, causing loss of control, saw

blade binding and kickback.

• Feed workpiece at an even pace. Do not

bend or twist the workpiece. If jamming occurs,

turn the tool off immediately, unplug the tool

then clear the jam. Jamming the saw blade by

the workpiece can cause kickback or stall the

motor.

• Do not remove pieces of cut-off material while

the saw is running. The material may become

trapped between the fence or inside the saw

blade guard and the saw blade pulling your

fingers into the saw blade. Turn the saw off and

wait until the saw blade stops before removing

material.

• Use an auxiliary fence in contact with the table

top when ripping workpieces less than 2 mm

thick. A thin workpiece may wedge under the rip

fence and create a kickback.

4.7 Kickback causes and related warnings

• Never stand directly in line with the saw blade.

Always position your body on the same side

of the saw blade as the fence. Kickback may

propel the workpiece at high velocity towards

anyone standing in front and in line with the

saw blade.

• Never reach over or in back of the saw blade

to pull or to support the workpiece. Accidental

contact with the saw blade may occur or

kickback may drag your fingers into the saw

blade.

• Never hold and press the workpiece that is

being cut off against the rotating saw blade.

Pressing the workpiece being cut off against the

saw blade will create a binding condition and

kickback.

• Align the fence to be parallel with the saw

blade. A misaligned fence will pinch the

workpiece against the saw blade and create

kickback.

• Use extra caution when making a cut into

blind areas of assembled workpieces. The

protruding saw blade may cut objects that can

cause kickback. Note, the above safety warning

only applies to tools where such cuts are

permitted by design and instruction.

• Support large panels to minimise the risk of

saw blade pinching and kickback. Large panels

tend to sag under their own weight. Support(s)

must be placed under all portions of the panel

overhanging the table top.

• Use extra caution when cutting a workpiece

that is twisted, knotted, warped or does not

have a straight edge to guide it with a mitre

gauge or along the fence. A warped, knotted,

or twisted workpiece is unstable and causes

misalignment of the kerf with the saw blade,

binding and kickback.

• Never cut more than one workpiece, stacked

vertically or horizontally. The saw blade could

pick up one or more pieces and cause kickback.

• When restarting the saw with the saw blade

in the workpiece, centre the saw blade in the

kerf so that the saw teeth are not engaged in

the material. If the saw blade binds, it may lift

Содержание Fusion2 2022

Страница 2: ...2 www igmtools com...

Страница 3: ...3 www igmtools com...

Страница 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Страница 19: ...19 www igmtools com Fence assembly...

Страница 20: ...20 www igmtools com Mitre gauge blade guard...

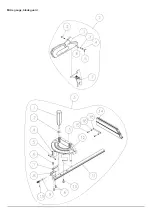

Страница 21: ...21 www igmtools com Motor and trunnion...

Страница 22: ...22 www igmtools com Cabinet...