-17-

www.igmtools.com

10. Trouble-Shooting

Machine will not start or continues to trip the breaker.

Possible Causes

1. Start capacitor at fault.

2. Motor connection wired wrong.

3. Wiring at fault.

4. Motor Start/Stop switch at fault.

5. Motor at fault.

6. Run capacitor at fault.

7. Wall circuit breaker tripped or at fault.

8. Power supply switched OFF or at fault.

9. Plug/receptacle at fault or wired incorrectly.

Possible Solution

1. Test/replace if faulty.

2. Correct motor wiring connections.

3. Check/fix broken, disconnected, or corroded wires.

4. Replace switch.

5. Test/repair/replace.

6. Test/replace if faulty.

7. Ensure circuit size is correct/replace weak breaker.

8. Ensure power supply is on/has correct voltage.

9. Test wires and contacts; correct the wiring.

Machine is excessively loud or is experiencing excessive vibration.

Possible Causes

1. Motor or component loose

2. Blade at fault

3. Motor mount loose/broken

4. Machine incorrectly mounted

5. Arbor pulley loose

6. Belts worn or loose

7. Pulley loose or at fault

8. Arbor bearings at fault

9. Motor bearings at fault

Possible Solution

1. Inspect/replace damaged bolts/nuts, and re-tighten with thread-

locking fluid.

2. Replace warped/bent blade; re-sharpen dull blade.

3. Tighten/replace.

4. Tighten mounting bolts; relocate/shim machine.

5. Retighten/replace arbor pulley.

6. Adjust tension of/replace belt

7. Realign/replace shaft, pulley, setscrew, and key.

8. Replace arbor housing bearings; replace arbor.

9. Test by rotating shaft; grinding/loose shaft requires bearing

replacement.

Machine trips the overload, or feels underpowered during operation.

Possible Causes

1. Feed rate/cutting speed too fast

2. Workpiece material unsuitable for machine

3. Pulley/sprocket slipping on shaft

4. Motor bearings at fault

5. Contactor at fault

6. Motor overheated

7. Workpiece crooked; fence not aligned

8. Machine undersized for task; wrong blade

9. Run capacitor at fault

10. Belt is slipping from pulley

11. Motor wired incorrectly

12. Plug/receptacle at fault

13. Motor at fault

Possible Solution

1. Decrease feed rate/cutting speed.

2. Only cut wood; ensure moisture is below 20%.

3. Replace loose pulley/shaft.

4. Test/repair/replace.

5. Test for good contacts/correct wiring.

6. Clean motor, let cool, and reduce workload.

7. Straighten or replace workpiece; adjust fence.

8. Use correct blade; reduce feed rate or depth of cut.

9. Test all legs for power/replace if faulty.

10. Adjust tension of/replace belt.

11. Test/repair/replace.

12. Wire motor correctly.

13. Test/repair/replace.

WARNING:

1. Wiring should only be done by professional electricians. Always make sure the machine is properly earthed.

2. All wirings in the cabinets should be protected against direct contact to at least IP2X when finishing electrical installation.

3. All exposed conductive parts should be connected to the protective bonding circuit.

4. Close and lock the door of cabinets.

WARNING:

1. Enough space around the machine and the cabinets should be kept in order to maintain conveniently.

2. The machine should be installed in a workshop with good illumination and ventilation.

3. Over-voltage protection device should be provided by end user on spot.

Содержание Fusion2 2022

Страница 2: ...2 www igmtools com...

Страница 3: ...3 www igmtools com...

Страница 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Страница 19: ...19 www igmtools com Fence assembly...

Страница 20: ...20 www igmtools com Mitre gauge blade guard...

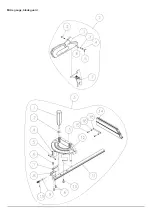

Страница 21: ...21 www igmtools com Motor and trunnion...

Страница 22: ...22 www igmtools com Cabinet...