-10-

www.igmtools.com

and nuts to the short rear fence guide and

the back left of the table. STOP BEFORE

TIGHTENING: Keep bolts loose until entire rail

assembly is in place to properly level rail.

2. Attach short rear fence support

Repeat step 1 for the longer rear fence section

with (3) bolts, lock washers, washers, and nuts.

Use the same assembly diagram in Step 1.

NOTICE: If the fence hooks are not yet

installed, now is a good time to do so.

3. Attach short rear fence support

To level the rear fence with the table top,

place a rigid straight edge on top of the rails.

Apply downward force at both arrow indicators

and simultaneously tighten the bolts with the

supplied Allen key and wrench.

4. Attach T-slot bolts to front table

Loosely fasten the (5) square headed bolts, (5)

washers, and (5) nuts. A couple revolutions of

the bolt will be tight enough. Prepare to insert

the (2) aluminium front rail sections.

5.Insert the long front fence support

Insert the long Front Rail. STOP BEFORE

TIGHTENING: Keep these bolts loose until the

entire rail assembly is in place to properly level

the rail.

6. Insert short rail and switch

Insert the short front rail into the first square

head bolt. IMPORTANT: Insert the switch

assembly before joining the two front rail

pieces. STOP BEFORE TIGHTENING.

7. Join front fence supports

Align the pins and join the two front rail pieces

and firmly push together.

8. Align the front rail with blade

Using the blade notching on the measuring

tape, align the entire front rail section to the

blade.

9. Level and fasten front rail

To level the front rail sections to the table top,

use a ridged straight edge atop the loosely

fit rail sections. Apply downward force to the

straight edge while keeping the two sections

firmly together. Simultaneously fasten down the

bolts.

10. Install the fence

Install the fence by placing the front end

first. Be sure that the handle is in the open,

unlocked, position prior to installing.

11. Level the table saw with casters and fix

Level the table saw with the ground and fix the

machine on the floor with screws.

6.5 Installing/removing the throat plate

1. Unplug the table saw!

2. Insert the throat plate back end first.

3. Lower the throat plate to the table.

4. Lock the throat plate with the thumb-lock.

5. Level the throat plate with the table using

the cat screws.

Note: This machine is shipped with a zero-

clearance throat plate that has already been

cut at the factory. Because of this, there may be

some residue already in the saw.

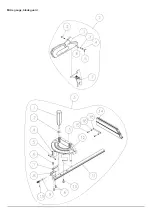

Installing the throat plate

WARNING: MAKE SURE SAW IS

UNPLUGGED. To remove or install the throat

plate, first set it to the unlock position. Then,

insert the rear end first and tilt the other end

down into position.

Levelling the throat plate

Pic. 34

To level the throat plate, adjust the leveling

screws.

Note: Make sure the throat plate is lower than

the cast iron table. Having the throat plate

higher at any position can interfere with the

workpiece feed and cause injury or harm and

increase the chance of kickback

6.6 Installing/removing safety accessories

A: Saw blade

B: Riving knife housing

C: Cam action lever

D: Riving knife

E: Blade guard

F: Blade compliant markings

Содержание Fusion2 2022

Страница 2: ...2 www igmtools com...

Страница 3: ...3 www igmtools com...

Страница 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Страница 19: ...19 www igmtools com Fence assembly...

Страница 20: ...20 www igmtools com Mitre gauge blade guard...

Страница 21: ...21 www igmtools com Motor and trunnion...

Страница 22: ...22 www igmtools com Cabinet...