-13-

www.igmtools.com

Better

A dial indicator on a mitre gauge.

Best

A dedicated saw dial indicator. Such as this one

by ‘Iagging’.

1. Un-plug the tablesaw!

2. Take initial measurement.

WARNING: MAKE SURE SAW IS

UNPLUGGED. With the throat plate and all

attachments removed, raise the blade to the

highest position at 90 degrees with the table.

Take an initial measurement about 1 cm from

the ground edge of the blade as shown.

3. Take relative measurement

Keep the mitre gauge against the left rail

and slowly move crossed the blade. Take

the second measurement and compare with

the initial measurement. Adjust the table to

compensate false measurements. There are 3

bolts to loosen prior to adjusting the table, see

step 4.

4. Loosen the three table fastener bolts.

5. Adjust as needed.

Loosen Table Bolts

Locate and loosen right side table to cabinet

bolt (above the tool holder).

Loosen Table Bolts

Locate and loosen left side table to cabinet bolt

(above the motor cover).

Loosen Table Bolts

Locate and adjust the rear table to cabinet bolt.

Adjusting or Installing Extension Wings: (may

be pre-installed):

To install or remove the extension wings, an

advised method is provided. This method

makes it easy to make the extension wings flat

with the table but requires the use of two ridged

supports and four clamps.

1. Unplug the table saw!

2. Clamp supports to table.

3. Place extension wing on supports.

4. Join or adjust the wing with supplied bolts.

Note: The clamps may scratch the tabletop!

Use a cloth or soft wood between

the clamp and the iron surfaces.

2. Take initial measurement

WARNING: MAKE SURE SAW IS

UNPLUGGED. Clamp two wooden supports

to the underside of the table saw as shown.

Straight 2x4 lumber will work

3. Take relative measurement

Place the extension wing on the supports and

place into position.

4. Join or adjust wing

You will need (4) m10 bolts and (4) washers to

fasten each extension wing to the table top. Be

sure to align the extension wing to the table top

prior to tightening the bolts.

7.3 Arbor and Tilt Adjustments

Adjusting the Blade Tilt Limits

You can check the arbor (blade) tilt limits with

an angle finder or 45-degree triangle. If these

limits are not within 0 degrees and 45 degrees,

use the following steps to adjust.

1. Unplug the table saw!

2. Remove the motor cover.

3. Remove the tool storage cover.

4. Locate tilt adjustment screws.

5. Adjust as needed.

6. Adjust the scale and indicator as needed.

Use caution: From the factory, the tilt limits

are pre-set to 0 and 45 degrees tilt to the left.

Adjusting this limit will slightly alter that amount

which may cause throat plate or fence to

interfere. Adjusting these limits should only be

done to set the tilt limits to 0 and 45 degrees.

2. Remove motor cover

WARNING: MAKE SURE SAW IS

UNPLUGGED.

To access the left side tilt limit adjustment

screw, remove the motor housing cover using

a #2 Philips head driver. There are 4 screws in

total holding on the motor cover.

Содержание Fusion2 2022

Страница 2: ...2 www igmtools com...

Страница 3: ...3 www igmtools com...

Страница 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Страница 19: ...19 www igmtools com Fence assembly...

Страница 20: ...20 www igmtools com Mitre gauge blade guard...

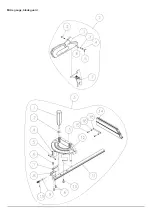

Страница 21: ...21 www igmtools com Motor and trunnion...

Страница 22: ...22 www igmtools com Cabinet...