-9-

www.igmtools.com

Receiving your tablesaw

This is how machine is shipped from the

factory.

Unscrew the crate fasteners

Use a drill with a #2 Phillips head bit and

remove the bottom screws from carton. These

screws may be discarded.

Lift crate off pallet

Use two persons to lift the carton away from the

pallet. There should be three packages along

with the table saw.

NOTE: The throat plate, riving knife, and 10”

blade is pre-installed in the machine. The miter

gauge, and blade changing tool are positioned

in the tool holder located on the right side of the

cabinet.

Check Inventory

1. Fence, install tools, push stick, blade guard

assembly

2. Smaller fence rail sections, hardware kit

3. Longer fence rail sections.

Wipe off protective plastics

Peel back the protective vinyl plastic and wipe

away the oil with a waste rag.

Use Caution: An oily rag can be a serious fire

hazard. Discard in an appropriate manner.

Tech Tip: To help keep your table top clean and

to prevent or clean any rust, we recommend

waxing your tabletop with an appropriate wax

rubbing compound. This will also reduce friction

under operation. Rust can be removed with

WD-40.

6.2 Inventory

Box 1

Fence: PTSF236110175-0130-1-1

Push stick: PTSF236110175-0130-130

Blade guard: PTSF236110175-01302-1

Install Tools

Fence hooks*: PTSF236110175-0130-118

* Fence storage hooks may be pre-installed.

Box 2

Rear Rail 2: PTSF236110175-0130-127.5

Front Rail 2: PTSF236110175-0130-127.6

Hardware kit

Box 3

Rear rail 1: PTSF236110175-0130-127.5

Front rail 1: PTSF236110175-0130-127.6

Pre-installed on machine

Throat plate

PTSF236110175-0130-6

Riving knife

PTSF236110175-0130-27

250mm blade

PTSF236110175-0130-33

Mitre gauge

PTSF236110175-0130-3

Arbor wrench

PTSF236110175-0130-137

Tool storage

PTSF236110175-0130-120

Wings (2x)

PTSF236110175-0130-4

Note: The front rail part number is comprised of

two pieces – both long and short. The rear rail

part number is comprised of two pieces – long

and short.

Note.: For safety reasons, this machine is not

sold with a tape-rule for the left side of the

blade. It is not a missing part.

6.3 Loose Parts & Overview

Your new machine has been mostly assembled

at the certified ISO 91001 factory where it was

made. Some parts must be assembled by the

purchaser. Please read all steps first before

proceeding with step one.

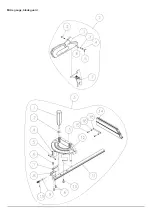

Blade Guard

5) M8x1.5+ lock nut

(5) Square head 8x1.5 + nut

Fence hooks (step 2)

6.4 General Setup

1. Attach the short rear fence support

2. Attach the long rear fence support

3. Level the rear rails and fasten

4. Attach T-Slot bolts to front table

5. Insert long front rail fence support

6. Insert short front rail and switch

7. Join front fence supports

8. Align the entire front rail to blade mark

9. Level and fasten the front rail

10. Insert fence

11. Level the saw by adjusting casters

1. Attach short rear fence support

Use the supplied wrench and Alan key to

loosely fasten (2) bolts, lock washers, washers,

Содержание Fusion2 2022

Страница 2: ...2 www igmtools com...

Страница 3: ...3 www igmtools com...

Страница 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Страница 19: ...19 www igmtools com Fence assembly...

Страница 20: ...20 www igmtools com Mitre gauge blade guard...

Страница 21: ...21 www igmtools com Motor and trunnion...

Страница 22: ...22 www igmtools com Cabinet...