SERVICE PROCEDURE

MAINTENANCE

4-60

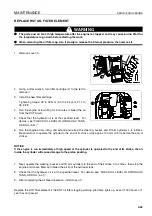

2.

Depress the brake pedal, keep it depressed, and push in

the rod (2) of the gauge until contacts the piston.

3.

Wear (A) is the amount that end face (C) of rod (2) is pro-

truding from end face (D) of guide (3). Measure the

amount of protrusion.

The point where groove (E) of the rod is level with end face

(D) of the guide is permissible limit (B) for the disc wear.

If this point has been reached, please ask your Komatsu

distributor to carry out inspection and replacement of the

parts.

q

If the disc is near the wear limit, carry out inspection at

shorter intervals, regardless of the specified inspection

interval.

4.

Install cap nut (1).

Tightening torque: 29.4 to 39.2 N·m (3.0 to 4.0 kgf·m, 21.7

to 28.9 lbft)

REMARK

On new machines, the position of the guide is adjusted so that the end face of rod (2) comes to the end face of

guide (3). For this reason, do not loosen locknut (4) except when replacing the disc.

Carry out the operation with two workers: one worker depresses the brake pedal and the other worker pushes in

rod (2).

CLEAN AND CHECK TURBOCHARGER

4

If there is carbon or oil sludge stuck to the blower impeller, it will lower the performance of the turbocharger or

cause it to break, so ask your Komatsu distributor to carry out the cleaning.

CHECK ACCUMULATOR GAS PRESSURE

4

When carrying out the EVERY 2000 HOURS SERVICE or EVERY YEAR SERVICE or when making periodic

replacement of the critical safety parts, please ask your Komatsu distributor to check the accumulator gas pres-

sure.

CHECK VIBRATION DAMPER

4

Check that there are no cracks or peeling in the outside surface of the rubber.

If any cracks or peeling are found, contact your Komatsu distributor to have the parts replaced.

Содержание WA320-5H

Страница 2: ...FOREWORD 11...

Страница 17: ...CONTENTS FOREWORD 1 16...

Страница 23: ...CE CONFORMING EQUIPMENT FOREWORD 1 22...

Страница 24: ...SAFETY 12...

Страница 25: ...SAFETY 2 2...

Страница 60: ...OPERATION 13...

Страница 181: ...TROUBLESHOOTING OPERATION 3 122...

Страница 182: ...MAINTENANCE 14...

Страница 243: ...SERVICE PROCEDURE MAINTENANCE 4 62...

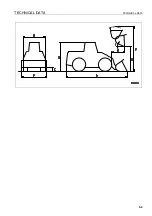

Страница 244: ...TECHNICAL DATA 15...

Страница 246: ...TECHNICAL DATA TECHNICAL DATA 5 3...

Страница 248: ...ATTACHMENTS OPTIONS 16...

Страница 313: ...CENTRAL LUBRICATION SYSTEM ATTACHMENTS OPTIONS 6 66...

Страница 314: ...INDEX 17...

Страница 315: ...INDEX 7 2...

Страница 318: ...NOTES 18...

Страница 319: ...NOTES NOTES 8 2 NOTES 8...

Страница 320: ...NOTES NOTES 8 3...

Страница 321: ...2003 Komatsu Hanomag GmbH All Rights Reserved Printed in Europe 10 2003...