SERVICE PROCEDURE

MAINTENANCE

4-54

LUBRICATING

4

1.

Using a grease pump, pump in grease through the grease fittings marked by the arrows.

2.

After greasing, wipe off any old grease that was pushed out.

(1) Center hinge pin (2 places)

(2) Engine stop solenoid linkage (1 place)

CHECK TIGHTENING PARTS OF TURBOCHARGER

4

Please contact your Komatsu distributor to have the tightening portions checked.

CHECK PLAY OF TURBOCHARGER ROTOR

4

Please contact your Komatsu distributor to have the rotor play checked.

CHECK ALTERNATOR DRIVING BELT TENSION AND REPLACEMENT

4

Since inspection and replacement of the fan belt require special tools, contact your Komatsu distributor.

REMARK

The machine is equipped with an auto tensioner, so there is no need to adjust the tension.

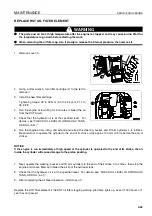

If the alternator drive belt is in the following condition, the belt

must be replaced. Please ask your Komatsu distributor to

replace the belt.

q

When horizontal scratch (1) crosses vertical scratch (2)

q

When there are tears (3) in part of the belt

In case (4) where there are horizontal scratches only, there is

no need to replace the belt.

Содержание WA320-5H

Страница 2: ...FOREWORD 11...

Страница 17: ...CONTENTS FOREWORD 1 16...

Страница 23: ...CE CONFORMING EQUIPMENT FOREWORD 1 22...

Страница 24: ...SAFETY 12...

Страница 25: ...SAFETY 2 2...

Страница 60: ...OPERATION 13...

Страница 181: ...TROUBLESHOOTING OPERATION 3 122...

Страница 182: ...MAINTENANCE 14...

Страница 243: ...SERVICE PROCEDURE MAINTENANCE 4 62...

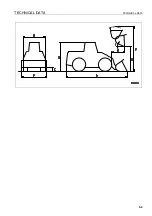

Страница 244: ...TECHNICAL DATA 15...

Страница 246: ...TECHNICAL DATA TECHNICAL DATA 5 3...

Страница 248: ...ATTACHMENTS OPTIONS 16...

Страница 313: ...CENTRAL LUBRICATION SYSTEM ATTACHMENTS OPTIONS 6 66...

Страница 314: ...INDEX 17...

Страница 315: ...INDEX 7 2...

Страница 318: ...NOTES 18...

Страница 319: ...NOTES NOTES 8 2 NOTES 8...

Страница 320: ...NOTES NOTES 8 3...

Страница 321: ...2003 Komatsu Hanomag GmbH All Rights Reserved Printed in Europe 10 2003...