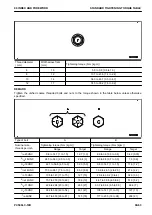

Standard clearance and standard value

• The clearance made when new parts are assembled is

called the standard clearance, which is indicated by the

range from the minimum clearance to the maximum clear-

ance.

• When some parts are repaired, the clearance is generally

adjusted to the standard clearance.

• The values indicating performance and function of new

products or equivalent are called "standard value", which is

indicated by a range or a target value.

• When some parts are repaired, the value of performance/

function is set to the standard value.

Standard interference

• When the diameter of a hole of a part shown in the given standard dimension and tolerance table is smaller

than that of the shaft to be inserted, the difference between those diameters is called "interference".

• Subtract the maximum dimension of the hole from the minimum dimension of the shaft and call it (A). Sub-

tract the minimum dimension of the hole from the maximum dimension of the shaft and call it (B). The range

between (A) and (B) is "standard interference".

• After repairing or replacing some parts, measure the dimension of their hole and shaft and check that the

interference is in the standard range.

Repair limit and allowable value or allowable dimension

• The dimension of parts changes due to the wear or deformation while they are used. When the dimension

changes exceeding certain value, parts cannot be used any longer. This value is called "repair limit".

• If a part is worn to the repair limit, it must be replaced or repaired.

• The performance and function of products lower while they are used. A value with which the product can be

used without causing a problem is called "allowable value" or "allowable dimension".

• A product whose dimension is out of the allowable value, must be repaired. However, since the allowable

values are generally estimated through various tests or experiences in most cases, the judgment must be

made in consideration of the operating condition and customer's requirement.

Allowable clearance

• Parts can be used until the clearance between them is increased to a certain limit. The limit at which those

parts cannot be used is called "allowable clearance".

• If the clearance between the parts exceeds the allowable clearance, they must be replaced or repaired.

Allowable interference

• The allowable maximum interference between the hole of a part and the shaft of another part to be assem-

bled is called "allowable interference".

• The allowable interference shows the repair limit of the part of smaller tolerance.

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

00 INDEX AND FOREWORD

00-60

PC500LC-10R

Содержание PC500LC-10R

Страница 1: ...HYDRAULIC EXCAVATOR SEN06722 00 PC500LC 10R SERIAL NUMBERS 100001 and up...

Страница 2: ......

Страница 3: ...00 INDEX AND FOREWORD PC500LC 10R 00 1...

Страница 76: ......

Страница 77: ...01 SPECIFICATIONS PC500LC 10R 01 1...

Страница 94: ......

Страница 95: ...10 STRUCTURE AND FUNCTION PC500LC 10R 10 1...

Страница 106: ...8 System operating lamp 9 Fusible link LAYOUT DRAWING OF BOOT UP SYSTEM 10 STRUCTURE AND FUNCTION 10 12 PC500LC 10R...

Страница 177: ...When balanced 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 83...

Страница 178: ...When lever is returned to fine control state CLSS 10 STRUCTURE AND FUNCTION 10 84 PC500LC 10R...

Страница 179: ...When lever is pulled at a stroke 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 85...

Страница 180: ...When lever is in stroke end CLSS 10 STRUCTURE AND FUNCTION 10 86 PC500LC 10R...

Страница 345: ...21 Center swivel joint 22 Travel motor 10 STRUCTURE AND FUNCTION LAYOUT DRAWING OF TRAVEL SYSTEM PC500LC 10R 10 251...

Страница 377: ...20 STANDARD VALUE TABLE PC500LC 10R 20 1...

Страница 406: ...Fig 13 Fig 14 Fig 15 MACHINE POSTURE AND PROCEDURE FOR MEASURING PER FORMANCE 20 STANDARD VALUE TABLE 20 30 PC500LC 10R...

Страница 407: ...30 TESTING AND ADJUSTING PC500LC 10R 30 1...

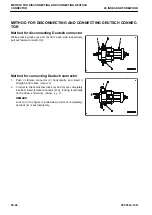

Страница 423: ...Socket Plug 30 TESTING AND ADJUSTING SKETCH OF TOOLS FOR TESTING AND ADJUSTING PC500LC 10R 30 17...

Страница 583: ...30 TESTING AND ADJUSTING METHOD FOR STARTING UP KOMTRAX TERMINAL PC500LC 10R 30 177...

Страница 604: ......

Страница 605: ...60 MAINTENANCE STANDARD PC500LC 10R 60 1...

Страница 619: ...MAINTENANCE STANDARD OF FINAL DRIVE 60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF FINAL DRIVE PC500LC 10R 60 15...

Страница 623: ...60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF SPROCKET TOOTH PROFILE FULL SCALE DRAWING PC500LC 10R 60 19...

Страница 626: ...MAINTENANCE STANDARD OF IDLER MAINTENANCE STANDARD OF IDLER 60 MAINTENANCE STANDARD 60 22 PC500LC 10R...

Страница 636: ...MAINTENANCE STANDARD OF MAIN PUMP 60 MAINTENANCE STANDARD 60 32 PC500LC 10R...

Страница 637: ...MAINTENANCE STANDARD OF SWING MOTOR 60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF SWING MOTOR PC500LC 10R 60 33...

Страница 638: ...MAINTENANCE STANDARD OF SWING MOTOR 60 MAINTENANCE STANDARD 60 34 PC500LC 10R...

Страница 641: ...60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF TRAVEL MOTOR PC500LC 10R 60 37...

Страница 643: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF CONTROL VALVE PC500LC 10R 60 39...

Страница 644: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 40 PC500LC 10R...

Страница 646: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 42 PC500LC 10R...

Страница 648: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 44 PC500LC 10R...

Страница 650: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 46 PC500LC 10R...

Страница 652: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 48 PC500LC 10R...

Страница 655: ...60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF WORK EQUIPMENT AND SWING PPC VALVE PC500LC 10R 60 51...

Страница 658: ...MAINTENANCE STANDARD OF TRAVEL PPC VALVE 60 MAINTENANCE STANDARD 60 54 PC500LC 10R...

Страница 668: ...MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE 60 MAINTENANCE STANDARD 60 64 PC500LC 10R...

Страница 674: ...DIMENSIONS OF BUCKET MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE 60 MAINTENANCE STANDARD 60 70 PC500LC 10R...

Страница 679: ...90 CIRCUIT DIAGRAMS PC500LC 10R 90 1...

Страница 690: ...Symbol Content Unit SYMBOLS USED IN HYDRAULIC CIRCUIT DIAGRAM 90 CIRCUIT DIAGRAMS 90 12 PC500LC 10R...

Страница 692: ......

Страница 694: ......

Страница 696: ......

Страница 698: ......

Страница 700: ......

Страница 704: ...Symbol Content Buzzer Antenna SYMBOLS USED IN ELECTRICAL CIRCUIT DIAGRAM 90 26 PC500LC 10R...

Страница 706: ......

Страница 708: ......

Страница 710: ......

Страница 712: ......

Страница 714: ......

Страница 716: ......

Страница 718: ......

Страница 720: ......

Страница 722: ......

Страница 724: ......

Страница 726: ......

Страница 728: ......

Страница 730: ......

Страница 732: ......

Страница 734: ......

Страница 736: ......

Страница 738: ......

Страница 740: ......

Страница 742: ......

Страница 744: ......

Страница 746: ......

Страница 748: ......

Страница 757: ......

Страница 758: ...PC500LC 10R HYDRAULIC EXCAVATOR Form No SEN06722 00 2018 KOMATSU All Rights Reserved Printed in Japan 11 2018...