MAINTENANCE PLAN

155

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION

4.7.7.a

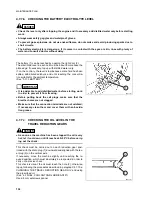

ADJUSTING THE FAN BELT TENSION

These maintenance operations must be carried out after the first 250 hours of operation, together with those to

be carried out “EVERY 250 HOURS”.

•

CHANGE THE OIL IN THE TRAVEL REDUCTION GEARS

•

CHECK AND ADJUST THE ENGINE VALVE CLEARANCE

For further details on the various maintenance operations, see the sections “4.7.10 MAINTENANCE EVERY

1000 HOURS OF OPERATION” and “4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION”.

For the inspection and adjustment, contact your Komatsu Utility Dealer.

The fan belt can be reached by opening the engine hood (See

“3.5.1 ENGINE HOOD”).

The check is manual: press the belt with your thumb on the indi-

cated point with a force equal to approx. 6 kg; the resulting de-

flection must be approximately 10÷15 mm.

If the deflection exceeds this value, loosen the nuts (1) and (2)

that fasten the alternator (3) and, with a lever inserted between

the motor block and frame, make the alternator slide.

Lock the nuts and check again.

Use a 13 mm spanner.

A -Fan pulley

B -Driving shaft pulley

C -Alternator pulley

IMPORTANT

☞

•

If the belt is worn, change it and check the tension again

after a few hours of operation.

RWA09210

RWA09230

3

2

1

RWA09220

10

÷

15 mm

A

C

B

Содержание PC20R-8

Страница 2: ......

Страница 12: ...10...

Страница 20: ...18...

Страница 21: ...SAFETY AND ACCIDENT PREVENTION...

Страница 23: ...SAFETY NOISE AND VIBRATION PLATES 21 MACHINE WITH CANOPY RWA00010 RWA00030 RWA00020 RYA11890...

Страница 27: ...SAFETY NOISE AND VIBRATION PLATES 25 LIFTING POINT DO NOT LIFT MORE THAN 1000 kg RWA04920 1000 Kg RWA00210...

Страница 54: ...52...

Страница 55: ...THE MACHINE AND ITS OPERATIONS...

Страница 118: ...116...

Страница 119: ...MAINTENANCE...

Страница 172: ...170...

Страница 173: ...TECHNICAL SPECIFICATIONS...

Страница 182: ...180...

Страница 183: ...AUTHORISED OPTIONAL EQUIPMENT...