41/KODAK M-SERIES PROJECTORS

Direction of Shifting Operation

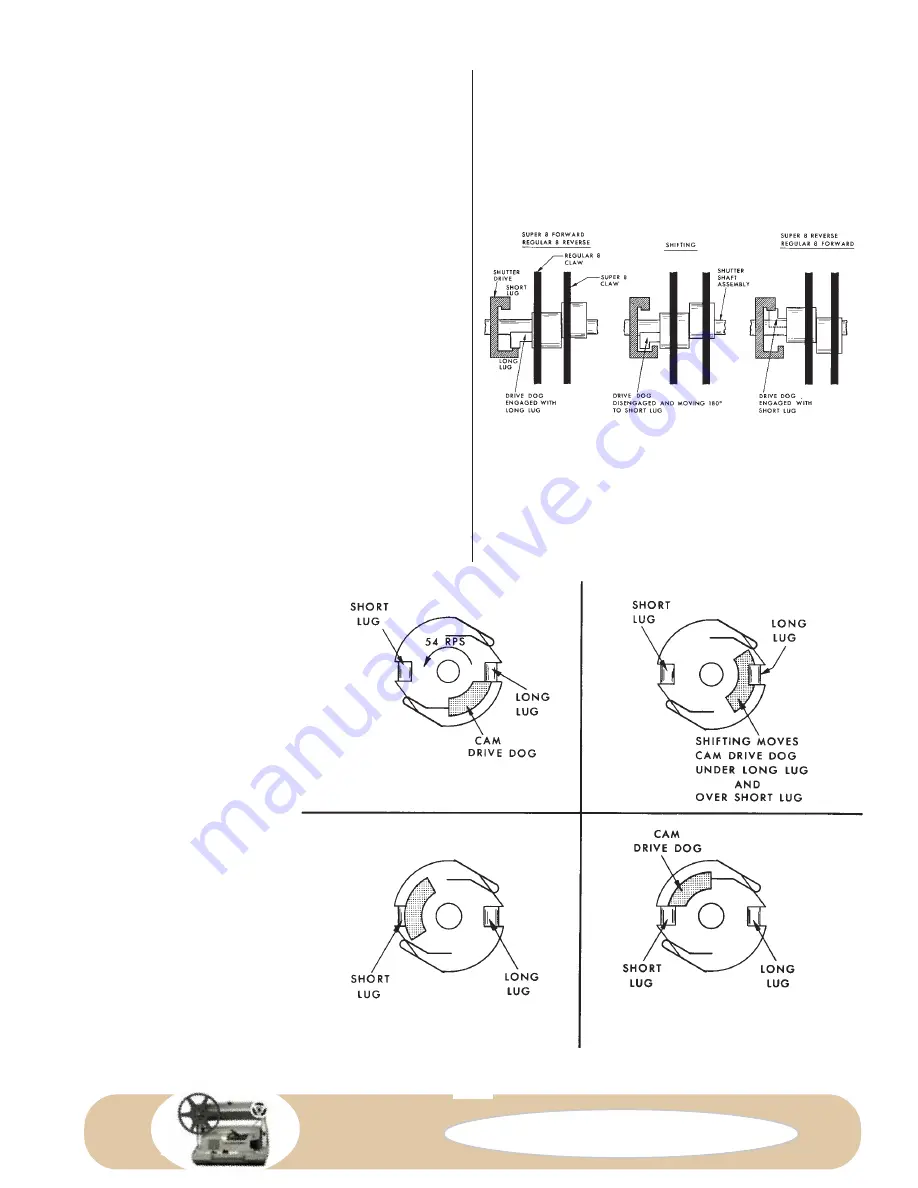

Because the motor turns the shutter-drive shaft in the same

direction at a constant 54rps at all times, shifting from

forward to reverse involves changing the phasing between

the up-and-down cam (on the shutter-drive shaft) and the

in-and-out cam (driven by the shutter). Remember that the

shutter and the shutter-drive shaft can rotate and slide

relative to each other.

In the super-8

Forward

running position, the cam dog

drives the long shutter lug (Fig. K12 and Fig. K15) and the

pulldown claw enters the film perforations at the start of

the down stroke.

Shifting direction: the directional shift lever pushes

against the shutter-drive shaft and moves it and the drive

dog to the left, Fig. K13, closer to the shutter and pinion

assembly.

The cam-drive dog is now disengaged (Fig. K13 and Fig.

K16) from the shutter assembly and is free to rotate

relative to it.

The cam-drive dog rotates 180° until it reaches the short

shutter lug, Fig. K14 and Fig. K18. This is the super 8

Reverse

running position. The pulldown claw enters the

film perforations at the start of the upstroke.

To change direction again, the directional shift lever

releases the shutter shaft, and a

spring moves the shutter-drive

shaft and drive dog back to the

right; the cam-drive dog is free to

rotate 180°until it again engages

the long lug and this again is the

super-8

Forward

running position.

In the regular-8

Reverse

running

position, the cam dog drives the

long shutter lug, Fig. K12 and Fig.

K15, and the pulldown claw enters

the film perforations at the start of

the upstroke, Fig. K11.

Shifting direction: the directional

shift lever pushes against the

shutter-drive shaft and drive dog

and moves it to the left.

The cam-drive dog is now disen-

gaged, Fig. K13 and Fig. K17,

from the shutter assembly and is

free to rotate relative to it.

The cam-drive dog rotates 180°

until it reaches the short shutter

lug, Fig. K14 and Fig. K18. This

is the regular-8

Forward

running

position. The pulldown claw

enters the film perforations at the

start of the downstroke.

FIG. K12 FIG. K13 FIG. K14

To change direction again, the directional shift lever

releases the shutter-drive shaft and drive dog, and a spring

moves the shutter-drive shaft back to its original position;

the cam-drive dog is free to rotate 180°until it again

engages the long lug and this again is the regular-8

Reverse

running position.

FIG. K15

FIG. K16

FIG. K17

FIG. K18

Compliments of:

www.KodakParts.com

Содержание Instamatic M Series

Страница 50: ...Compliments of www KodakParts com...

Страница 51: ...Compliments of www KodakParts com...

Страница 52: ...Compliments of www KodakParts com...

Страница 53: ...Compliments of www KodakParts com...

Страница 54: ...Compliments of www KodakParts com...

Страница 55: ...Compliments of www KodakParts com...

Страница 56: ...Compliments of www KodakParts com...