33/KODAK M-SERIES PROJECTORS

completely out of the film aperture at the slowest run-

ning speed, the snap ring is too far in. Move the snap

ring closer to the lower end of the still-mask changeover

rod—the direction of arrow #1, Fig. D112.

-if the still-frame heat-absorbing filter doesn't move

completely into the film aperture at the still setting, the

snap ring is too far out. Increase the distance between

the snap ring and the lower end of the still-mask

changeover rod—move the snap ring in the direction of

arrow #2, Fig. D112.

2. Forward/reverse arm.

As you change between forward

and reverse, the forward/reverse arm shifts the position of

the shutter-drive shaft. The forward/reverse arm pushes the

shutter-drive shaft slightly closer to the shutter at the reverse

setting. At the forward setting, the forward-reverse arm

allows the shutter-drive shaft to move slightly away from the

shutter.

The in/out position of the shutter-drive shaft determines

which of two lugs on the shutter will be engaged by the drive

dog at the end of the shutter-drive shaft. In Fig. D113 and

Fig. D114, we've assembled a shutter to the shutter-drive

shaft to illustrate the operation.

On reverse, you've seen that the forward/reverse arm pushes

the shutter-drive shaft toward the shutter. The dog at the end

of the shutter-drive shaft then picks up the inner lug at the

back of the shutter, Fig. D113. On forward, the spring-driven

shutter-drive shaft moves slightly away from the shutter. The

dog at the end of the shutter-drive shaft then picks up the

outer lug at the back of the shutter, Fig. D114.

Watch the shutter-drive shaft as you shift the projector

between forward and reverse—make sure the dog on the

shutter-drive shaft engages the proper lug on the shutter. If

the shutter-drive shaft won't move back far enough to engage

the outer lug on the shutter, adjust the eccentric on the

forward/reverse arm, Fig. D116. Similarly, adjust the

eccentric if the shutter-drive shaft won't move in far enough

to engage the inner lug on the shutter. But first make sure

that the shutter-drive shaft is free to move in. If one of the

springs at the back of the shutter is bent, it may be blocking

the shutter-drive shaft, Fig. D115.

3. Testing film advance.

For safety, always install the

bottom cover before plugging in the projector. If you've just

repaired the projector, it's not as necessary as yet to replace

the bottom-cover screws—just make sure the bottom cover is

in place.

Next install the lamp and the film-path cover plate. Also

replace the pressure plate, Fig. D117, and the lens; it's not

necessary to replace the front cover for tests and adjust-

ments. You can now check the projector with test film. If

you're repairing the projector for someone else,

always use

test film

—don't risk damage to the customer's film.

When you're checking with super 8 film, install the super-8

adapter over the supply spindle. Remove the super-8 adapter

to check with regular-8 film.

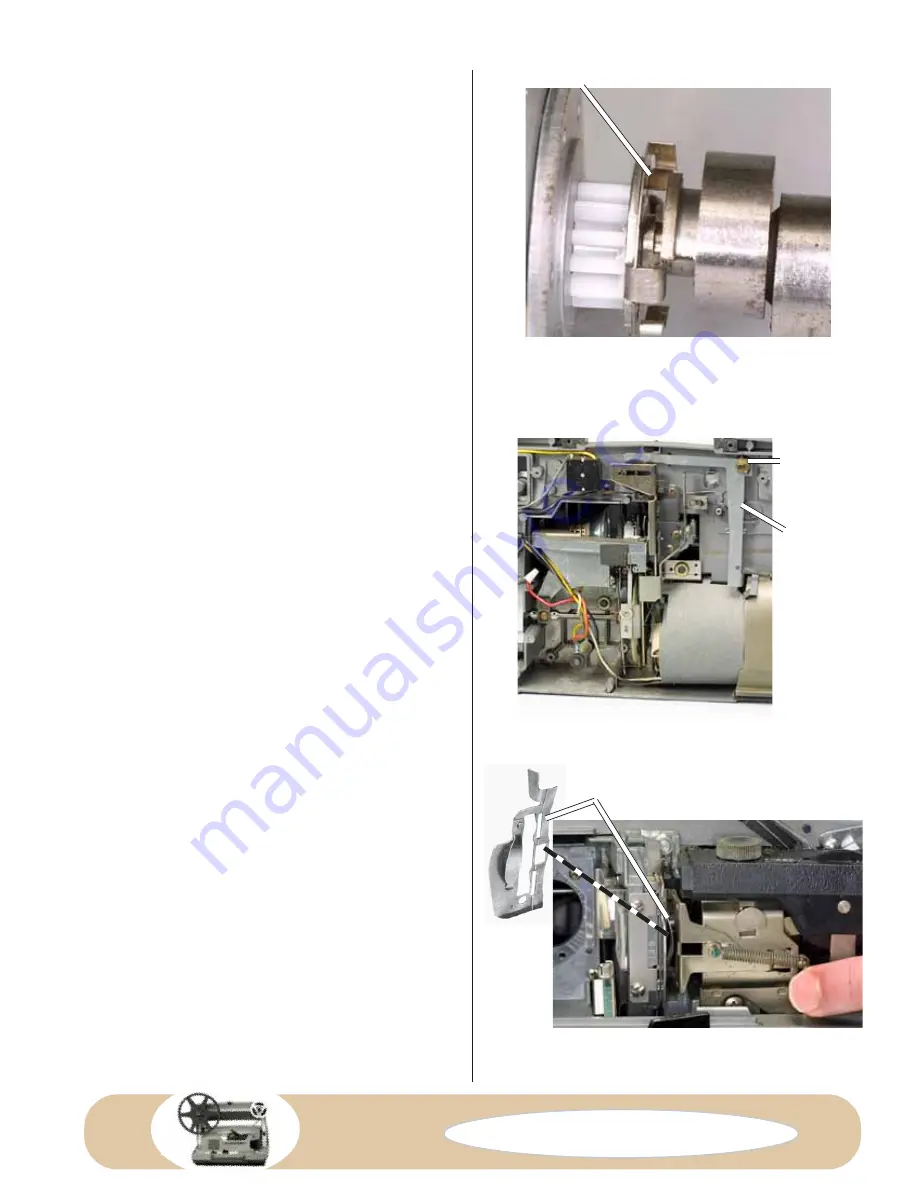

BENT SPRING BLOCKING SHUTTER-DRIVE SHAFT

FIG. D115 Shutter-drive shaft and shutter—

here a bent spring at the back of the shutter is

preventing the shutter-drive shaft from moving

to the reverse position.

FIG. D116 Back of projector.

FIG. D117 Front of projector—pressure plate

installed.

PRESSURE PLATE

FORWARD/

REVERSE

ARM

ECCENTRIC

Compliments of:

www.KodakParts.com

Содержание Instamatic M Series

Страница 50: ...Compliments of www KodakParts com...

Страница 51: ...Compliments of www KodakParts com...

Страница 52: ...Compliments of www KodakParts com...

Страница 53: ...Compliments of www KodakParts com...

Страница 54: ...Compliments of www KodakParts com...

Страница 55: ...Compliments of www KodakParts com...

Страница 56: ...Compliments of www KodakParts com...