118

For horizontal refrigerant pipe, the distance

between supporters should not be exceed

1m.

For vertical refrigerant pipe, the distance

between supporters should not be exceed

1.5m.

13. Connect the pipe to indoor unit and

outdoor unit by using two spanners.

Be sure to use two spanners and proper

torque to fasten the nut, too large torque

will damage the flare, and too small torque

may cause leakage. Refer the following

table for different pipe connection.

Pipe

Diameter

Torque

Sketch map

(kgf.cm)

(N.cm)

1/4" (6.35)

144~176 1420~1720

3/8" (9.52)

333~407 3270~3990

1/2" (12.7)

504~616 4950~6030

5/8" (15.9)

630~770 6180~7540

3/4" (19)

990~1210 9270~11860

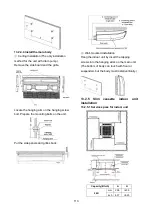

13.4.3 First-Time Installation

Air and moisture in the refrigerant system

cause the following problems:

●

Increases in system pressure

●

Increases in operating current

●

Decreases in cooling and heating efficiency

●

Blocks in capillary tubing caused by

moisture in the refrigerant circuit freezing

●

Corrosion of parts in the refrigerant system

caused by water

The indoor units and the pipes between

indoor and outdoor units must be tested for

leakages and evacuated to remove gas and

moisture from the system.

Gas leak check with soap water:

Apply soap water or a liquid neutral

detergent on the connections with a soft brush

to check for leakage in the pipe connecting

points. If bubbles emerge, the pipes are

leaking.

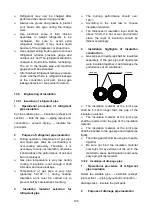

1. Air Purging Using the Vacuum Pump

1) Completely tighten the flare nuts on the

indoor and outdoor units. Confirm that both

the2-way and 3-way valves are set to the

closed position.

2) Connect the charge hose with the push pin

of the Handle Lo to the 3-way valve gas

service port.

3) Connect the charge hose of the Handle Hi

to the vacuum pump.

4) Fully open the Handle Lo of the manifold

valve.

5) Turn on the vacuum pump to begin

evacuation.

6) Conduct a 30-minute evacuation. Check

whether the compound meter indicates

-0.1Mpa(14.5Psi). If the meter does not

indicate -0.1Mpa(14.5Psi) after 30 minutes

has elapsed, continue evacuation for 20

more minutes. If the pressure does not

reach -0.1Mpa(14.5Psi) after 50 minutes

has elapsed, check if there are any leaks.

Fully close the Handle Lo valve of the manifold

valve and turn off the vacuum pump. After 5

minutes, confirm that the gauge needle is not

moving.

7) Turn the flare nut on the 3-way valve45°

counterclockwise for 6-7 seconds. Once

gas begins to come out, tighten the flare nut.

Make sure the pressure display on the

pressure indicator is higher than

atmospheric pressure. Then remove the

charge hose from the 3-way valve.

8) Fully open the 2-wayand 3-way valves and

securely tighten the cap on the 3-way valve.

Содержание KDIP012-H2

Страница 8: ...5 2 2 Part names of Indoor Outdoor units Cassette Units ...

Страница 9: ...6 KDIR Duct Units ...

Страница 10: ...7 KDIP Duct Units ...

Страница 11: ...9 Ceiling floor Units ...

Страница 12: ...10 HESP DUCT Units ...

Страница 19: ...19 2 3 4 7 Outside Water Pump for Optional When Ceiling Installation ...

Страница 31: ...33 KSIE024 H220 O KSIR036 H218 inch 37 2 16 1 31 9 40 6 26 5 15 9 ...

Страница 34: ...36 Ceiling floor Units ...

Страница 39: ...41 KTIR036 H2G1 KTIR048 H2G1 ...

Страница 40: ...43 KUIR18 H2 KUIR24 H2 ...

Страница 41: ...44 KFUF036 H2G1 KFUF048 H2G1 ...

Страница 42: ...45 KFUF060 H2G1 ...

Страница 43: ...46 KFUF036 H2G1 KFUF048 H2G1 ...

Страница 44: ...47 KDIP090 H2 KDIP012 H2 KDIP018 H2 KDIP24 H2 ...

Страница 69: ...74 6 2 Outdoor Unit KSIE018 H220 O KSIE024 H220 O ...

Страница 70: ...75 KSIE009 H221 O KSIE012 H220 O ...

Страница 71: ...77 KSIR036 H218 ...

Страница 77: ...83 KDIR09 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 78: ...84 KDIR12 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 79: ...85 KDIR18 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 80: ...86 KDIR24 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 96: ...104 12 Field Wiring 9K 24K 36K 48K 60K ...

Страница 97: ...105 ...

Страница 147: ...155 P U P V ...

Страница 148: ...156 P W P N ...

Страница 174: ...184 4 Remove the evaporator support board 5 Screw off the fixing screws to remove the evaporator 4 screws 1 screw ...

Страница 181: ...191 4 Remove the evaporator fixing clamps to disassemble the evaporator Fixing clamps 1 screw ...

Страница 188: ...221 5 Remove the four fixing screws of the fan motor then remove the motor 5 ...

Страница 201: ...234 6 Remove the grounding screw 7 Remove the Wires 1 2 3 or L1 L2 S Then remove the electronic control box 7 5 ...