V:\Mark\AP-F6 Operation Manual.doc

17

JST

AP-F6 PNEUMATIC CRIMPING MACHINE

Step 5.

Replace the terminals in the Index wheel,

re-connect the air and electricity supplies,

and refit the Safety Guard.

7. CRIMPING MACHINE MAINTENANCE

7.1 Lubrication

Ensure that the ram is regularly lubricated

with a general purpose machine oil

(approximately once every week).

7.2 Cleaning

The crimping dies are chrome plated, and

as a result they require polishing at regular

intervals with a good quality metal polish to

ensure that the terminals do not become

stuck in the punches due to a build-up of

deposits. If the deposits are not removed,

the terminals may become bent during the

stripping operation.

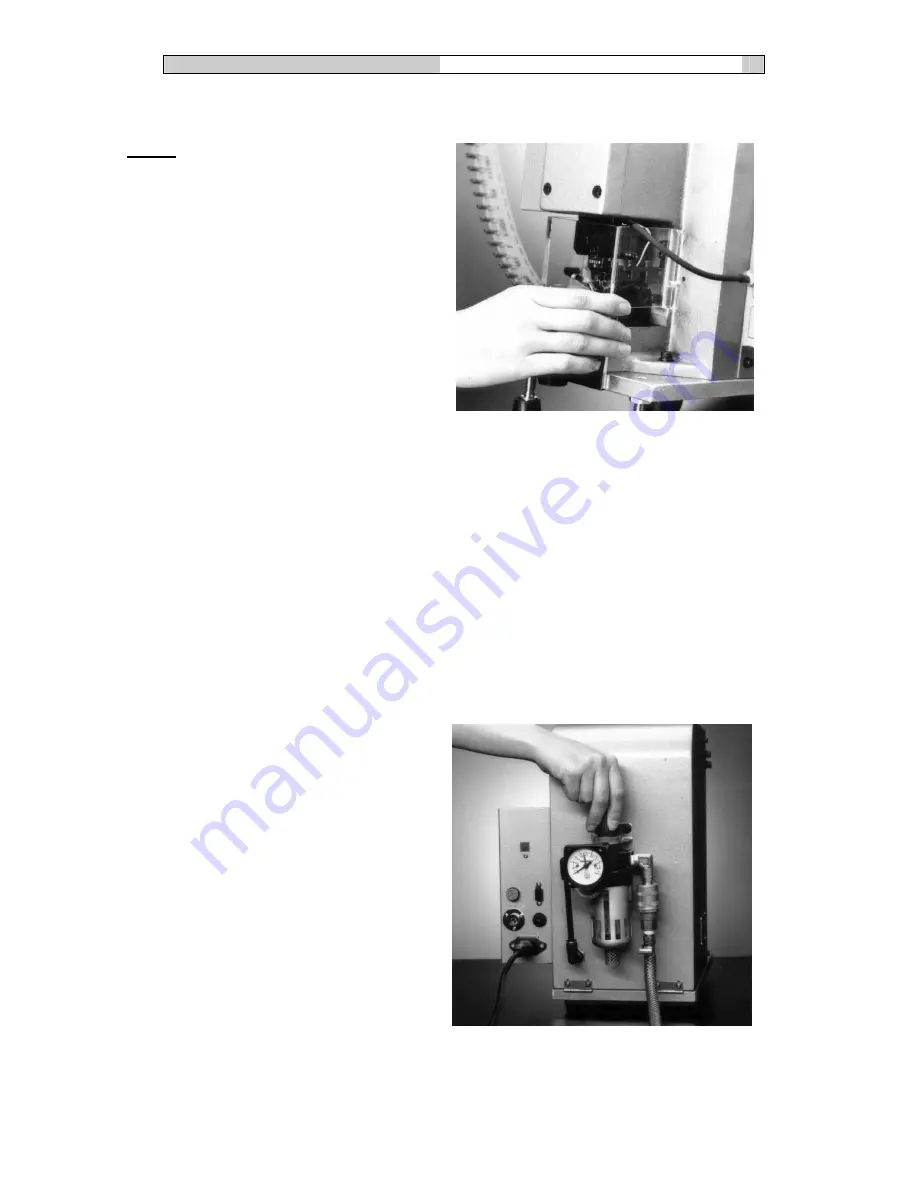

7.4 Filter Regulator adjustment

The air pressure on the Filter Regulator is

factory set to 0.6 MPa before despatch.

If the pressure is not set to this figure, the

regulator will require adjustment using the

following method:-

Pull the knob on top of the regulator in an

upward direction and rotate in either a

clockwise or counter-clockwise direction

until the gauge reads the correct pressure.

Push the knob down to lock it in position

once the correct pressure is achieved.

7.3 Shut Height Adjustment

The shut height of the press is factory set so

that when the ram is at Bottom Dead Centre,

the conductor crimp dies are closely touching to

ensure that the correct crimp height is

achieved.

If the linkage becomes worn it is possible that

the shut height will not be correct and the crimp

height will fluctuate.

If this problem occurs, contact the J.S.T.

Technical Services Department, because the

setting of the crimp height requires special

tooling.