6

The disc filtration systems can be clogged by water-for-

med deposits. The formation of these deposits depends

on the quality of the filtered water and environmental

conditions like temperature, pH, light, duration of filtra-

tion and more.

The most common water-formed deposits are:

1. Biological or organic (mostly mucous or oily/ beige,

brown or green in color).

2. Iron oxide (rust) or other metal oxides.

3. Carbonates (white or gray).

4. Combinations of the above.

If these deposits cannot be eliminated by pretreatment

of the water, we recommend the following cleaning

procedure.

Material and Equipment.

Chose a well ventilated working place

• 2 small containers (1 liter), 2 large containers (15

liter) and a stirring stick, all resistant to chemicals,

preferably in polypropylene.

• Plastic rope to tie up the discs.

• Sodium Hypochlorite NaOCl (commercial concentra-

tion: 10%). Oxidizes and removes organic and biologi-

cal deposits.

• Hydrochloric Acid HCl (commercial concentration:

30%). Very corrosive liquid that dissolves and removes

carbonates, iron oxide, and other deposits.

Steps for seasonal maintenance of discs.

Seasonal Maintenance

Cleaning the Discs

6

Operation and maintenance manual

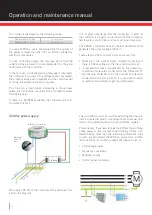

3

4

1

2

To clean carbonates and iron deposits, put the discs in a

15 liter container that contains:

• 10 liters of water

• 2 liters of Hydrochloric Acid HCl 30%.

• Contact time: from 1 to 8 hours

• Agitate the discs several times with a stirring stick.

• Remove the discs carefully from the solution, put them

in the second large container with clean water and rinse

them very well before placing them back in the filter.

Make sure that the system is not under pressure! Release

the clamp (1) and remove the filter cover (2). Unscrew the

butterfly-nut on top of the filtration cartridge (3). Remove

the tightening cap (4). Remove the discs out of the car-

tridge spine (5).

• Personal protection equipment: safety glasses, gloves,

long pants, long sleeved shirt and shoes.

To clean organic and biological deposits, put the discs in

a 15 liter container that contains:

• 5 liters of water

• 5 liters of Sodium Hypochlorite NaOCl 10%.

• Contact time: up to 8 hours

• Agitate the discs several times with a stirring stick.

• Remove the discs carefully from the solution, put

them in the second large container with clean water

and rinse them very well before placing them back in

the filter.

Clean regularly the hydraulic command filter

The ¾’’ filter installed in the inlet HDPE manifold provides

clean water to command hydraulically the backwash valves.

For regular maintenance, close the manual ball valve, get the

cartridge out and clean manually.

Winter time

To prevent damages in the filtration station by water

freezing in winter time, drain the system by leaving a drai-

nage valve open.