5

Description and operation

Monthly Maintenance

How to work the automatic

filtration station

3

5

4

Filtmaster uses a unique disc filtration technology. The

double face thin PP grooved discs are compressed together

in the cartridge spine to create the filtering effective sur-

face that retains the suspended solids in the dirty water.

Thiis disc cartridge is resistant to pressure and corrosion.

In the filtration process, the discs are tightly compres-

sed together thanks to the spring and the differential

pressure inside the filter. The filtration is done when the

dirty water passes through the discs to the interior of the

cartridge spin.

Check for leakages in the drainage manifold

In case that there is a leakage of water during the filtration

stage, check the sealing joints of the backwash valves.

Check inlet and outlet pressure

In case that the differential pressure is above 0,6 bar

(9 psi), activate manually the backwash of the Filtmaster

filtration station. In case that the differential pressure

remains high check for possible failures in the internal

components of the automatic disc cartridges.

Controller performance

Check that the controller timing parameters are correctly

set up. Using the controller, activate an automatic bac-

kwash cycle.

1. Make sure that the inlet and outlet HDPE manifolds

are correctly connected.

2. Check that the automatic filtration station was not da-

maged during the transport.

3. Check that filter clamps are tightly closed.

4. Power up the system.

5. Pressurize the system checking that pressure does not

exceeds 10 bar.

6. Program the controller following the instructions in

this manual.

7. Check that pressure in the outlet HDPE manifold is at

least 2,5 bar.

Filter clogged during start-up.

1. Close the downstream sustaining pressure hydraulic

valve if exists.

Color-coded filtration degrees

Working conditions.

Colour

Yellow

Red

Blue

Green

Sky Blue

Violet

Screen

-

130

100

-

-

-

Discs

200

130

100

50

25

20

(microns)

Maximum pressure

10 bar

140 psi

Minimum pressure

2.5 bar

35 psi

Backwash flow (per filter)

7-28 m

3

/h

30-123 gpm

Maximum temperature

60°C

135°F

pH

4-13

4-13

Filtration station 3 x 2’’.

2. Operate manually several backwash cycles.

3. Open slowly the downstream hydraulic valve.

4. If the differential pressure remains high, check that the

flow to be filtered is not excessive. This could cause a

high head loss.

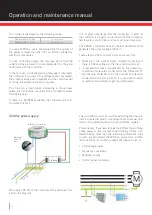

INLET

DRAINAGE

OUTLET

580

1.495

895

90

110

110

63

285