21

Pr

=

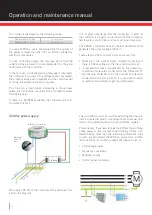

0.0 atm pfc 12:40

f03 00:18 FLUSHING ti

Out of schedule

…The Filtmaster filter cleaning controller is out of the time interval when it is authorised to clean

filters (displayed only if a cleaning interval time has been entered).

No permission

...The Filtmaster filter cleaning controller may be out of the time interval (if it is programmed) but

the cleaning permission input may not be activated (if it is programmed). Therefore, no operation is

done. This message is displayed if the user answered YES to the question of enabling inputs. In this

case, any automatic cleaning is conditioned to the activation of this input.

05-minute lag

…The Filtmaster filter cleaning controller already has permission to clean filters, but it is in a lag

mode (programmed by the user or 5 minutes pre-program), so pressure in the facility is stabilised to

prevent mistaken cleaning. This process takes place every time it is programmed at the beginning of

the cleaning permission and after each cleaning carried out.

F:01 00:28 cleaning

…Once the cleaning interval set by the user is up, or when the pressure gauge gives the signal, the

Filtmaster filter cleaning controller starts cleaning the first programmed filter. It displays on the

countdown counter what still remains before passing on to the following step.

F:02 06 pause

PAUSE (if this is programmed) before proceeding to clean the second filter. This process will be

repeated with every filter that is programmed by the user until the last one is cleaned.

F:08 00:01 cleaning

Once the cleaning is completed, the controller will go back to the LAG status.

05-minute lag

Once this is finished, the INTERVAL period will be displayed again.

Remaining v:0847 t:01:30

Until it goes to NO PERMISSION or OUT OF SCHEDULE

No request

OUT OF SCHEDULE

Remaining v:0847 t:01:30

…The Filtmaster filter cleaning controller is already in the process between cleanings once the lag

is over (if this was programmed) and it is now counting down time and volume to reach the next

cleaning. The Filtmaster filter cleaning controller has a cleaning interval that can be programmed by

time, volume or both, depending on the devices of the facility or on the user’s preference.

On top of that, the cleaning on demand of the differential pressure switch (if this is connected) is

always active. If the differential pressure switch gives the signal, the cleaning will start and then the

interval countdown (time/volume) will go back to their initial programmed position.

The REMAINING data are saved when finishing the PERMISSION period or entering the OUT OF

SCHEDULE period, these are kept so that, when back to the CLEANING status, not a single second

of the interval set by the user for the correct cleaning of the filtering station is lost.

Bottom line

Information on the current status of the cleaning and

remaining volume and time.

Reasons for cleaning

Keypad

At any time we can see in the screen what the controller

is doing and what devices are connected.

In this example, filter 3 is being cleaned, with 18 se-

conds remaining before cleaning the next filter. It is also

indicating that this cleaning process has been started by

time counter (TI).

TI

Cleaning activated because time countdown reached 0.

VO

Cleaning activated because volume countdown reached 0.

MD

Cleaning activated by the differential pressure switch.

MA

Cleaning manually activated through keypad of controller.

NOTE

Every time a cleaning is carried out for whatever

reason, both time and volume countdown coun-

ters start again with the information programmed

by the user.

F

1

7

0

9

5

4

2

3

6

8

FILTER AND TIME REMAINING

REASON FOR CLEANING