24

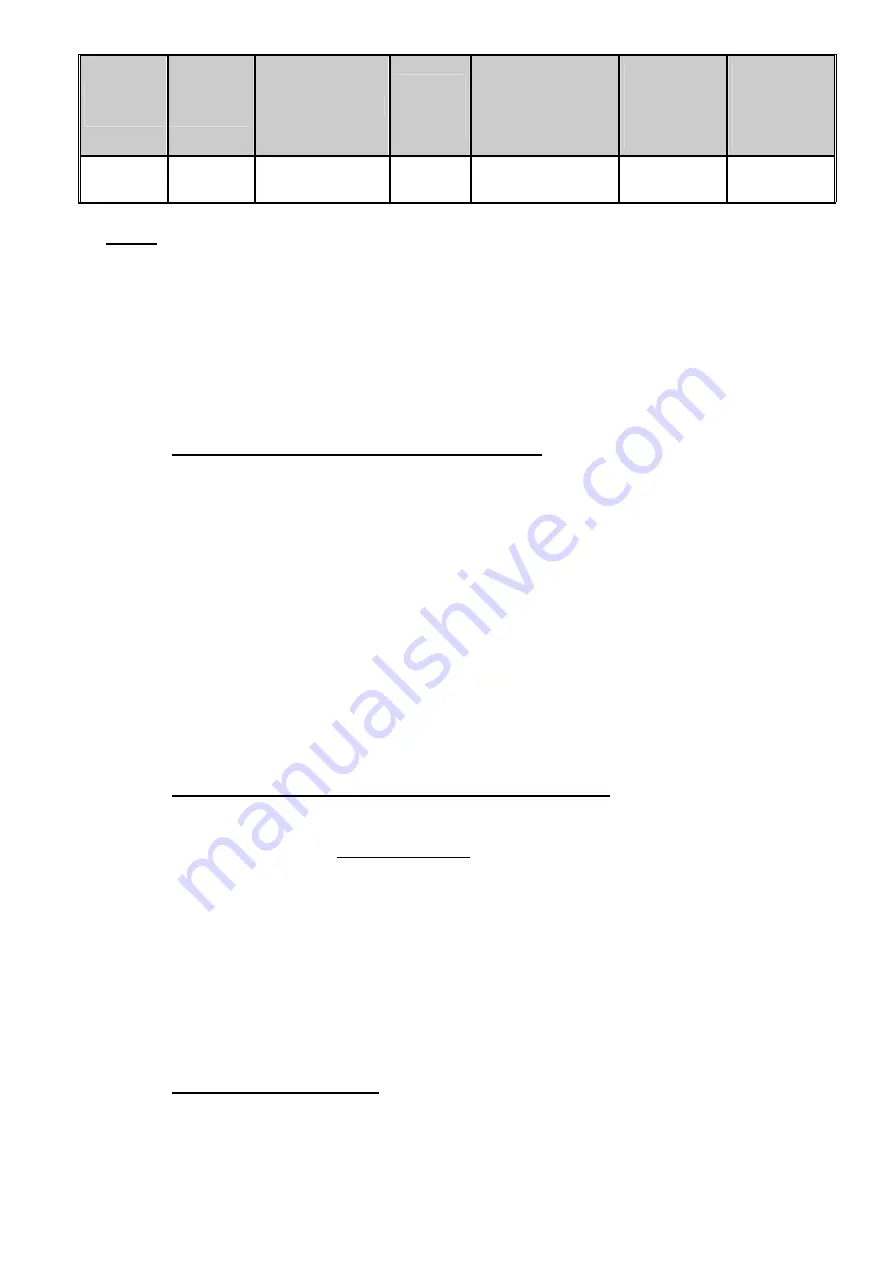

Limiter

type

External

diameter

Spring type

Number

of

springs

Adjustment

value

1mm = 1 turn

Corresponds to

Longuest

adjustment

dimension

maxL (mm)

Shortest

adjustment

dimension

minL (mm)

K 64/22

170 mm 60x20,5 x 2,0

6

about 35,0

daNm

53,0 47,5

NOTE

To avoid the limiter getting stuck, it is important to make sure, during the

adjustment or readjustment, that the shortest adjustment dimension is not lower than

the indicated dimension.

After adjustment, the elastic flange should be changed in the hexagon nut hole.

For greasing, only use special grease (Agraset 116 or 147).

A/

WITH HYDRAULIC TRACTOR PUMP

1-

Whilst unloading, when the resisting torque reaches the sliding torque towards the

centre of the hub which comes to a halt, they are driven back up by the two springs

in the rotating casing, which causes the noise.

2-

Disengage the tractor PTO and slow the tractor engine’s speed right down

.

3-

Invert

the moving floor’s speed to maximum, preferably for

10 seconds

, to bring

the heap of manure back towards the front.

4-

When the heap of manure is cleared from the spreading device,

restart the

tractor’s PTO

and gradually accelerate its speed.

5-

The limiter will then be activated again at about

200revs/min

. (PTO)

.

B/

WITH HYDRAULIC POWER UNIT (OPTION)

1-

When the limiter disengages,

keep the same rotating rate for the tractor’s PTO

(1000revs/min)

, and do not slow down in spite of the constant noise produced by

the two beating cams. The limiter can remain disengaged for a certain time without

risks for the cams or the carter’s notches.

2-

Invert

the moving floor’s speed to clear the heap of manure as explained above.

3-

Reduce the speed of rotation of the tractor’s PTO to about

200revs/min

to engage

the limiter again.

4-

Gradually

accelerate

the PTO’s speed of rotation.

C/

FOREIGN MATTERS

1-

When the limiter has difficulty engaging again, check that there are no foreign

matters in front or inside the spreading parts.