19

11-

Tractor with flow which exceeds 45 l/min

:

Provide a flow divider to be installed on the spreader, before the “PRESSURE”

orifice on the distributor unit, or contact your dealer to check whether it is possible to

adjust the tractor’s flow rate.

12-

Closed circuit tractor

: (Example: John DEERE)

a-

To operate the equipment without the tractor having problems, activate the tractor

distributor and immediately use the equipment’s hydraulic functions.

b-

As soon as the equipment’s hydraulic functions have been used, return the tractor’s

distributor to NEUTRAL.

c-

For earlier models of John Deere tractors (prior to the 6000 series), check that the

tractor’s hydraulic system is not vibrating and that the equipment’s return hose is

connected to the tractor’s filter bowl; this is to avoid CAVITATION and pump

unpriming (if you experience problems, contact your John Deere dealer).

4).

Electricity.

1-

See pages 15, 16 and 17 (section 6): Maintenance and repair.

2-

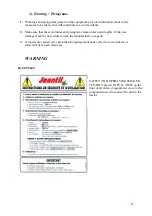

Read sticker page 11 (ref: 892 640).

All types of equipment (direct control from tractor or distributor) require electrical

power:

- Connection is made to the battery from a direct electrical line.

-Voltage:

12 volts

DC

- Two conductors:

2.5 mm²

the

brown

wire should be connected to

battery

+

,

and the

blue

wire to

battery

-

.

3-

Signalling:

The spreaders are equipped with rear signal lights, which comply with the French

Highway Code with standard

7

-contact connectors, type

12

N Normal,

ISO

standard 1724 N° NF 43.407,

which should be connected to the socket at the back

of the tractor.

9.

Adjustments and maintenance.

1).

Greasing.

1-

Whilst using the equipment,

grease every day.

2-

The various greasing points are arranged as follows:

- 1 greaser on the drawbar broaching pin (Reference 1).

- 1 greaser on the front bearing (Reference 2).

- 2 greasers on front pulley of moving floor (Reference 3).