18

07610-003-61-42-T

PREVENTATIVE MAINTENANCE

MAINTENANCE

The dishmachines covered in this manual are designed to operate with a minimum of

interaction with the operator. However, this does not mean that some items will not wear

out in time. Jackson highly recommends that any maintenance and repairs not specifi cally

discussed in this manual should be performed by QUALIFIED SERVICE PERSONNEL

ONLY. Performing maintenance on your dishmachine may void your warranty if it is still

in effect, so if you have a question or concern, do not hesitate to contact a QUALIFIED

SERVICE AGENCY.

There are many things that operators can do to prevent catastrophic damage to the

dishmachine. One of the major causes of component failure has to do with prescrapping

procedures. A dishmachine is not a garbage disposal; any large pieces of material that

are put into the machine shall remain in the machine until they are either broken up (after

spreading out on your ware!) or physically removed. Strainers are installed to help catch

debris, but they do no good if they are clogged. Have operators regularly inspect the pan

strainers to ensure (1) that they are free of soil and debris and (2) they are laying fl at in

the tub.

When cleaning out strainers, do NOT beat them on waste cans. The strainers are made

of metal and can be forgiving; but once severe damage is done, it is next to impossible for

the strainer to work in the way it was designed to. Wipe out strainers with a rag and rinse

under a faucet if necessary. For stubborn debris, a toothpick should be able to dislodge

any obstructions from the perforations. Always ensure that strainers are placed back in

the machine before operation and that they lay fl at in the tub.

You may wish to learn more about how your water hardness will effect the performance

of your machine. Hard water makes dishmachines work harder and decreases effi ciency.

Again, it is important to remind operators that trying to perform corrective maintenance

on the dishmachine could lead to larger problems or even cause harm to the operator. If

a problem is discovered; secure the dishmachine using proper shut down procedures as

listed in this manual and contact a QUALIFIED SERVICE AGENCY.

Some problems, however, may having nothing to do with the machine itself and no

amount of preventative maintenance is going to help. A common problem has to do

with temperatures being too low. Verify that the water temperatures coming to your

dishmachine match the requirements listed on the machine data plate. There can be a

variety of reasons why your water temperature could be too low and you should discuss

it with a QUALIFIED SERVICE AGENCY to determine what can be done.

PREVENTATIVE

MAINTENANCE

Содержание TEMPSTAR

Страница 2: ......

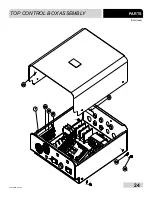

Страница 31: ...24 07610 003 61 42 T TOP CONTROL BOX ASSEMBLY PARTS Continued 26 1 29 28 30 33 34 36 ...

Страница 66: ...59 07610 003 61 42 T PARTS TEMPSTAR VENTLESS SYSTEM ASSEMBLY ...

Страница 74: ...07610 003 61 42 T 67 SCHEMATICS SOLID STATE 208 230V 50 60 HZ 1 3 PHASE TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Страница 75: ...07610 003 61 42 T TEMPSTAR 208 230V 50 60 HZ 1 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES 68 ...

Страница 76: ...69 07610 003 61 42 T SCHEMATICS SOLID STATE 460 V 60 HZ 3 PHASE TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Страница 77: ...70 TEMPSTAR 460 V 60 HZ 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Страница 79: ...72 TEMPSTAR LT NB 208 230V 50 60HZ 1 3 PHASE SCHEMATICS TEMPSTAR TOP MOUNT W CYCLE SWITCHES ...

Страница 80: ...73 07610 003 61 42 T SCHEMATICS TEMPSTAR NB LT 460V 50 60 HZ 3 PHASE TOP MOUNT UNIVERSAL TIMER ...

Страница 82: ...75 07610 003 61 42 T SCHEMATICS SDI OPTIONS ...

Страница 83: ...76 07610 003 61 42 T DRAIN QUENCH OPTIONS SCHEMATICS ...

Страница 85: ......