23

6X-1050a

3960 CAMERA

INSTALLATION AND OPERATION

The 1/4-20 fasteners threaded into these

holes must not protrude through the base more

than 0.1 inch.

The 3960 can be directly mounted to the wall

mount arm (section 4.3 below) or to any other

base that matches the 4.75-inch diameter hole

pattern on the 3960 Base.

Proceed as follows to install the 3960 on a

pedestal:

1. Route the cable pigtail down into the pedestal.

This cable should be secured by a strain relief and

not allowed to hang free within the pedestal if there

is a long cable run hanging underneath. (If an

access plate is not available at the top of the

pedestal, the system cable must first be connected

to the pigtail connector.)

2. Bolt the 3960 to the pedestal using stainless

steel hardware.

3. Attach the pigtail connector to the system

connector. This often is done through a removable

access plate. Be sure these cables are secured

with a strain relief so that they do not hang free with

long cable runs.

4. Verify that the 3960 will have a full range of

movement without striking any nearby structure.

5. Refer to section 3 to set up and check out the

3960.

4.2 LARGE BASE PLATE INSTALLATION

This plate is not required for any of the Cohu

supplied mounting arms and brackets covered in

this manual. It is an optional 8.5 inch diameter

base plate that attaches to the 3960 base plate to

provide additional mounting hole options.

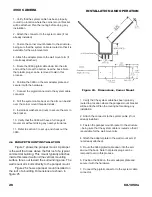

Figure 18 is the dimensional diagram of this

optional base.

It attaches to four threaded holes on the

3960 standard base with flathead 1/4-20 x 3/4

mounting screws. Use of flathead screws main-

tains the entire surface of the adapter plate flat for

placing on an existing on-site mounting base

These holes are on the 4.750 diameter

pattern. If site-supplied flathead screws are used

they must not protrude through the standard base

plate by more than 0.1 inch. More than this would

jam into the 3960 housing.

This optional base has two four-hole patterns

for mounting to a pedestal or other type mount. One

pattern is on a 7-inch diameter and the other on a

7.25-inch diameter pattern. Holes on each pattern

are spaced 90° from each other. These patterns are

offset from each other by 22.72°.

All support mounting holes are 0.380 diameter.

They are intended for 3/8-inch hardware. Use high

quality fasteners made from grade 316 stainless

steel.

4.3 WALL MOUNT INSTALLATION

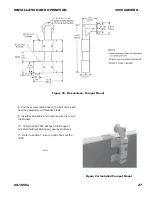

Figure 4 shows the wall mount arm. For a wall-

mount installation, the support arm bolts directly to

a wall. An adapter plate on the end of the arm

matches the hole pattern of a 3960 base. The 3960

is placed on the arm and is then bolted to it. This

arm is also used with the remaining three mounting

methods (pole, corner, and parapet).

Figure 22 shows dimensions of the basic wall

mount arm. The 0.38-inch diameter holes (slotted)

are suitable for use with 5/16-inch mounting hard-

ware. All mounting hardware should be of high

quality and made from grade 316 stainless steel.

This diagram does not show the adapter plate

on the end of the arm to which the 3960 fastens.

This adapter plate has four 1/4-20 threaded

holes on a 4.75-inch diameter hole pattern to match

the baseplate of the 3960.

The basic installation procedure is:

1. Verify that the system cable is accessible for

connection to the 3960 pigtail cable at the mounting

location.

2. Install a connector to the end of the system cable

(if not already installed).

3. Attach the adapter plate to the wall mount arm (if

not already attached).