Index Braille

Page 9

Manual Index Everest

January 2000

Verson 8.20/9.20

4

The sheet feeder

4.1

General function

The sheet feeder is designed to use paper in the weight range of 70-200 gsm. (grams per square

metre) Perfect function (a fault frequency maximum 1/1000) requires a paper suitable for the

printer, and a correctly installed sheet feeder. The experience we have from thousands of

Everest’s on the market, indicates that 80% of all good quality paper works perfectly with the

Everest.

4.2

Paper quality

There are a number of different paper qualities on the market which are labelled “Braille Paper”.

Normally they are in the range of 70-180 gsm (20-100 Pound).

To determine if the paper quality is suitable for the Everest check the following details:

a) The paper is properly cut. There should be a smooth and even surface when you feel with your

finger along the cutting edge of the paper.

b) Never use separated fan fold paper. The edges of this paper are very bad and can result in

double-feeding, or not feeding at all.

c) The paper must be a clean, with no holes or perforations on the sheet. Holes and perforation

are normally made with a punch, and as a result sheets can “stick” together.

d) Check that the surface of the paper has a texture similar to normal copy paper. The roughness

of the surface affects the difference between gliding and standing friction and is necessary for

proper function. The paper should not have a shiny or glossy surface. (Similar to playing cards.)

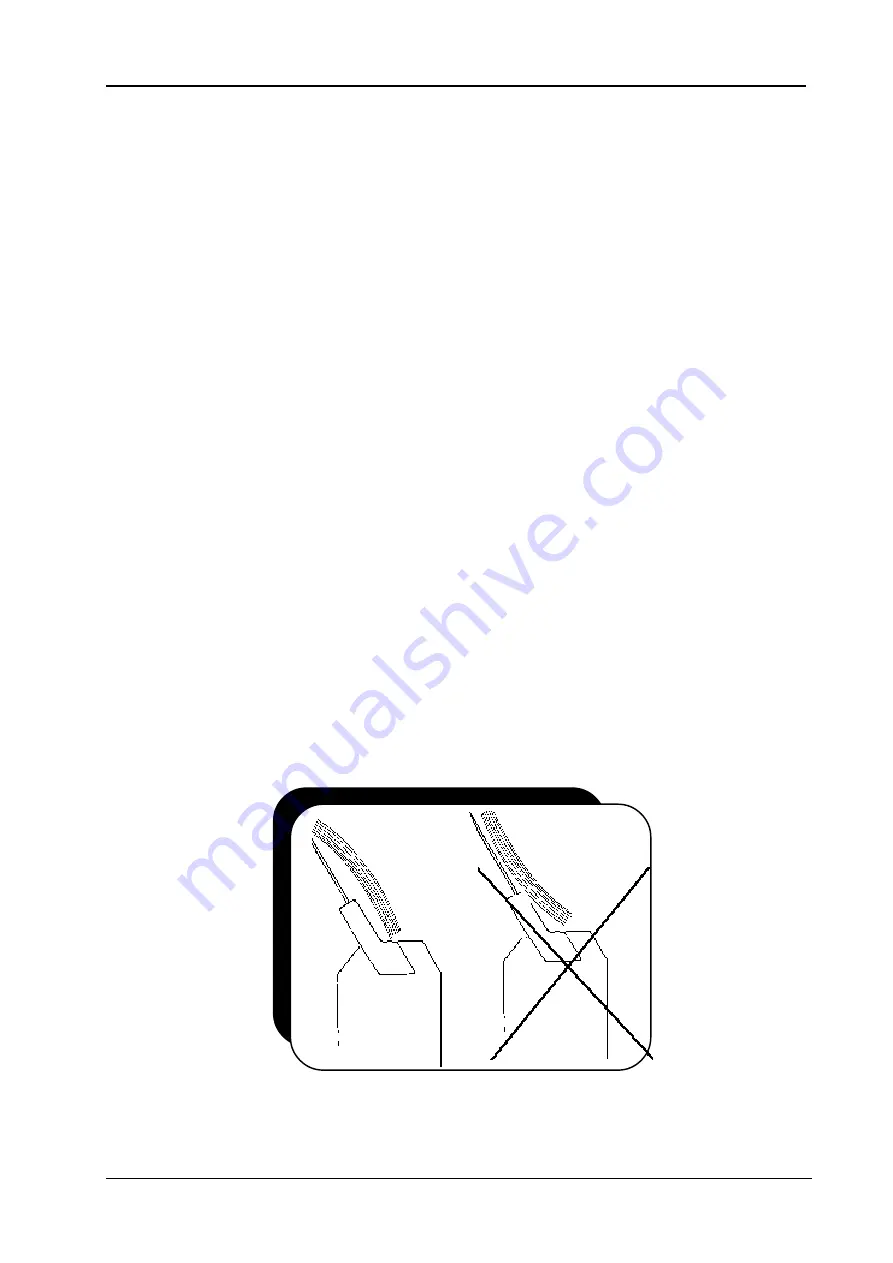

e) Ensure that the paper is flat and undamaged. If the paper is bent, it is important that the

curving of the paper is towards the front of printer. (See picture below)

f) Do not use dark coloured paper. It can interfere with the optical paper sensor.