14

STV50 ed 09/08

VICTRIX 50 Rev. 002

10

8

4

12

9

1

11

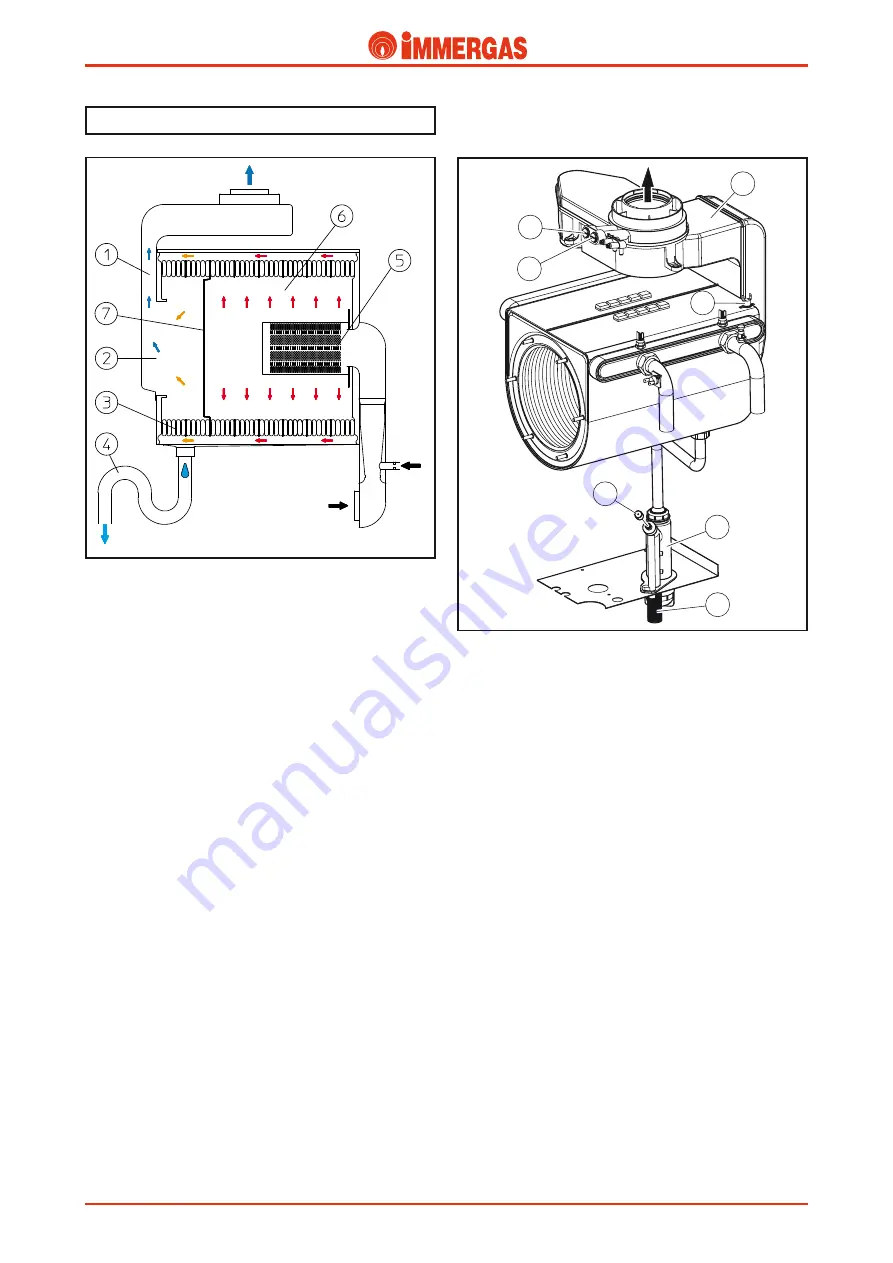

Condensate drain trap (4).

Collects the condensate that forms during boiler functioning

from the bottom of the module.

Its outlet is connected to the draining pipe (11) towards which

the passage of water is allowed but not the passage of fumes,

which could occur following obstruction of the evacuation

pipes.

The height of the column of water in the siphon is in fact

greater than the pressure detected inside the sealed chamber

(module)

with the fan at maximum speed and the evacuation

pipes blocked at functioning limits.

This, however, prevents the draining of combustion products

into the sewers.

On commissioning fumes may escape from the exhaust pipe

(11) which disappear after a few minutes of functioning when

the condensate has reached a sufficient height. If this should

take too long, fill the siphon with water after having removed

the cap (10), which must be re-positioned correctly at the end

of the operation.

Air-flue sample points (8-9).

There are two sample points in the upper part of the boiler

with screw fastening, with front access, after having removed

the plastic cover and from where the combustion agent air (8)

and combustion products (9) can be withdrawn.

Flue circuit.

Operating.

The functioning of the fan positioned at the entry of the air-

gas mixing pipe, guarantees the fan-assisted expulsion of the

fumes produced by the cylindrical burner (5).

These directly hit the first eight elements of the primary heat

exchanger inserted in the sealed combustion chamber (6) which

has a sheet steel section on its base (7) that divides it from the

condensation chamber (2) and diverts the flow of fumes to the

outside of the module.

In this way the flue gases, before entering the condensation

chamber (2), hit the last three elements (3) of the heat exchan-

ger, inside which primary circuit return water runs.

This cools the combustion products further and makes their

condensation easier before escape from the flue hood (1).

The water condensate formed inside the heat exchanger, in

the flue hood and also in the evacuation pipes flows into the

lower part of the module from where, before being discharged,

is conveyed into a trap (4).

Flue hood (1).

It is connected to the rear part of the condensation module

and conveys the combustion products towards the drain fitting

present in the upper part of the appliance.

It is affected by the passage of fumes and water condensate

formed inside it or in the exhaust pipes.

It is constructed in plastic, resistant to the corrosive effects of

the condensate and can work to a temperature of 130 °C

(max.

flue temp with flow 85° C = 78° C)

.

A flue safety thermostat is inserted onto the condensation

module (12), to protect the flue hood (1) and which intervenes

when the temperature detected on the condensation module

exceeds110° C.

Gas

Air

Condensate drain

Flue exhaust

Technical Documentation

Technical Documentation